5. Commissioning

5 Commissioning

5.1 Mechanical

installation

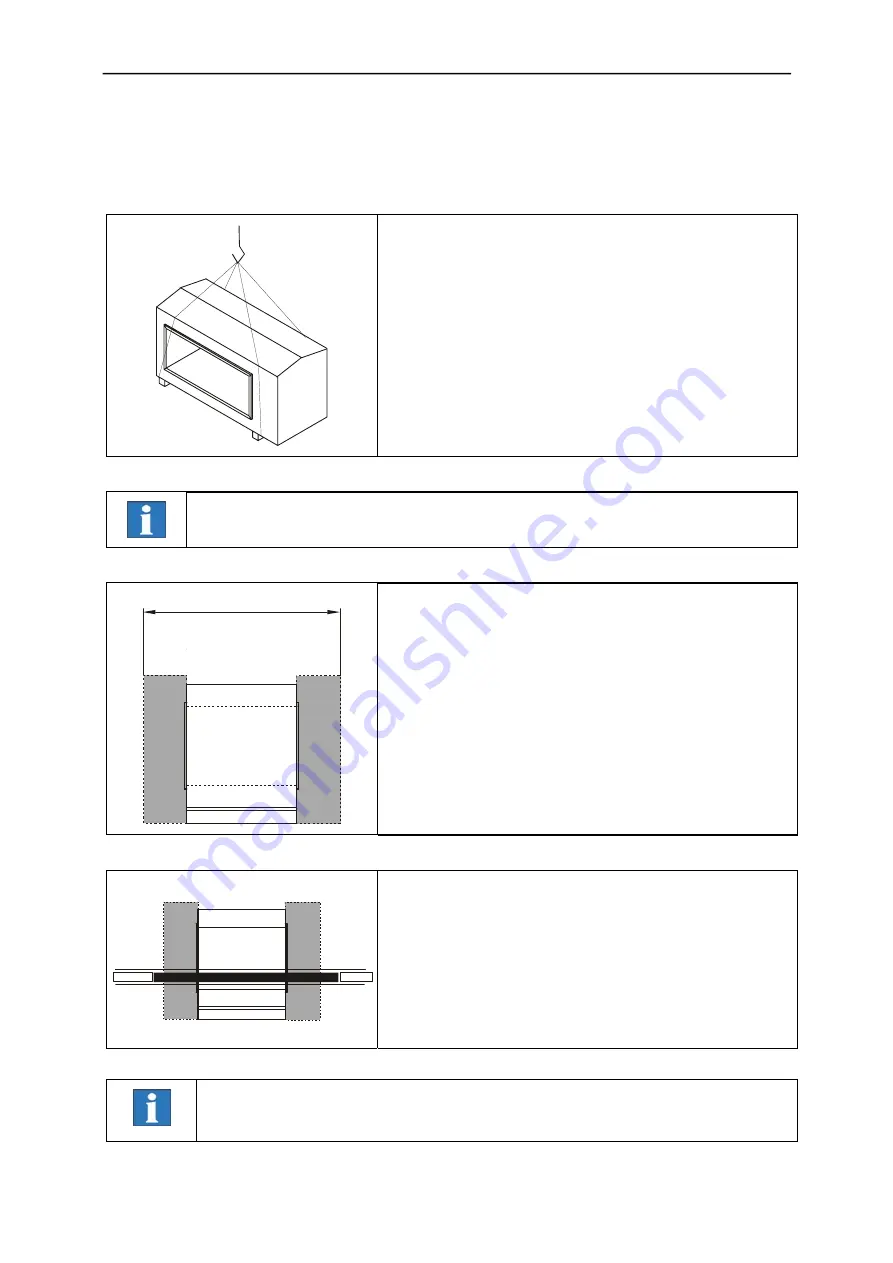

Use only enough stable lifting harnesses for big and heavy

detector heads.

Take care for a stable and vibrationproof mounting!

MZ

Metal-free zone must be strictly observed!

Within the metal-free zone no metallic parts must be situated.

For moving metal parts (pusher) the metal-free zone extends.

The dimensions of the metal-free zone are given in the at-

tached data sheet.

A nonmetallic slide (plastics or wood) must be used within

the aperture as a belt support.

The sliding board and also the run back belt underneath

should not touch the shaft walls inside of the detector

head opening.

The recommended gap between slide and detector is min.

10 mm.

Do not mount or operate the detector near sources of interferences (electric motors,

frequency and current converters). The required distance depends on the aperture size

of the detector head and the power of the source of interference.

12