6

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/

rpm

Anno di Fabbricazione:

Massa:

kg

SUPER SMART

LGA 226

4

3600

70,000

BH10X00000

Engine:

LOMBARDINI LGA 226

cm. 50

Mass (weight):

with wheels 3.50-6

with rotary tiller

83,5

81,5

<2,5

Test conditions

- P.T.O.: Disengaged - machinestationary on a

concrete plane surface

Test conditions:

- P.T.O.: Engaged

Sound

pressure on

operator’s ears

dB(A)

Sound

pressure on

operator’s ears

dB(A)

(Macchine

stationary

on a grass

surface)

(Macchine

stationary on a

concrete surface

with an interposed

elastic layer)

(Machine

running on a

concrete surface

with an interposed

elastic layer)

Acoustic power

dB(A)

Acoustic power

dB(A)

Acceleration

on hangrip

EN 1033 - 28662/1

m/sec

2

Acceleration

on hangrip

EN 1033 - 28662/1

m/sec

2

<2,5

89

87,5

104,5

102,5

11,75

11,75

With SICKLE BAR MOWER cm. 96

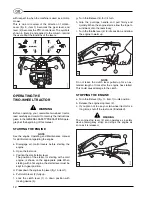

NOISE AND VIBRATIONS

TYPE OF MARKING

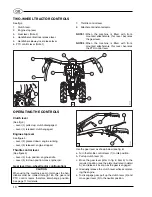

TWO-WHEEL TRACTOR

SUPER SMART - SUPER SMART Diesel

Models:

to

(punched on the gearbox)

SUPER SMART - SUPER SMART Diesel

A211408 A212096

Progressiv unit number starting from

Progressiv unit number starting from

AC00001

With SICKLE BAR MOWER cm. 96

With ROTARY TILLER cm. 50

With ROTARY TILLER cm. 50

-

-

Engine:

Mass (weight):

with wheels 3.50-6

with rotary tiller

HONDA GC 160

a cm. 50

Modello tipo:

N. Serie:

Mot.:

Potenza: 3,7 kW/

rpm

Anno di Fabbricazione:

Massa:

kg

SUPER SMART

GC 160

3600

66,500

BH10X00000

87,5

6,1

NO

NO

See NOTE

With ROTARY TILLER cm. 50

100

NO

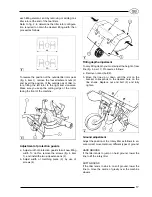

Engine:

YANMAR L48

cm. 50

Mass (weight):

with wheels 3.50-6

with rotary tiller

Modello tipo:

N. Serie:

Mot.:

Potenza:

kW/

rpm

Anno di Fabbricazione:

Massa:

kg

SUPER SMART Diesel

L48

3,4

3600

83,500

BH10X00000

TR1017-4GB

NOTE:

SUPER SMART Diesel model does not allow the use of front attachment.

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

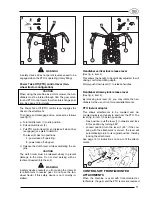

S/N reading:

type of machine

year of manufacturing

000 week of production

00

progressiv n° of production

X

00

000

BH10

GB

Содержание SUPER SMART

Страница 1: ...SUPER SMART SUPER SMART Diesel USE AND MAINTENANCE MANUAL GB...

Страница 2: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......