Press DOWN firmly on the cutter shaft lock. While holding the lever down - rotate the cutter by

hand until the cutter shaft lock clicks in to position. When turning the cutter by hand there is only

ONE locking position to be found. Once the cutter shaft lock is fully depressed - Hold it There.

You may now proceed with removing the cutter shaft lock nut and the cutter.

PLEASE . . . DONT FORGET

to pull UP on the cutter shaft lock when you are finished reinstalling

the cutter wheel. Pulling UP on the cutter shaft lock releases the cutter and the cutter shaft from the

locked position. Failure to unlock the cutter when attempting to cut a key may result in no rotation

of the cutter.

Please note

- the motor may be powerful enough to slip the belt and permanently

damage it by wearing a flat spot on the belt.

13.

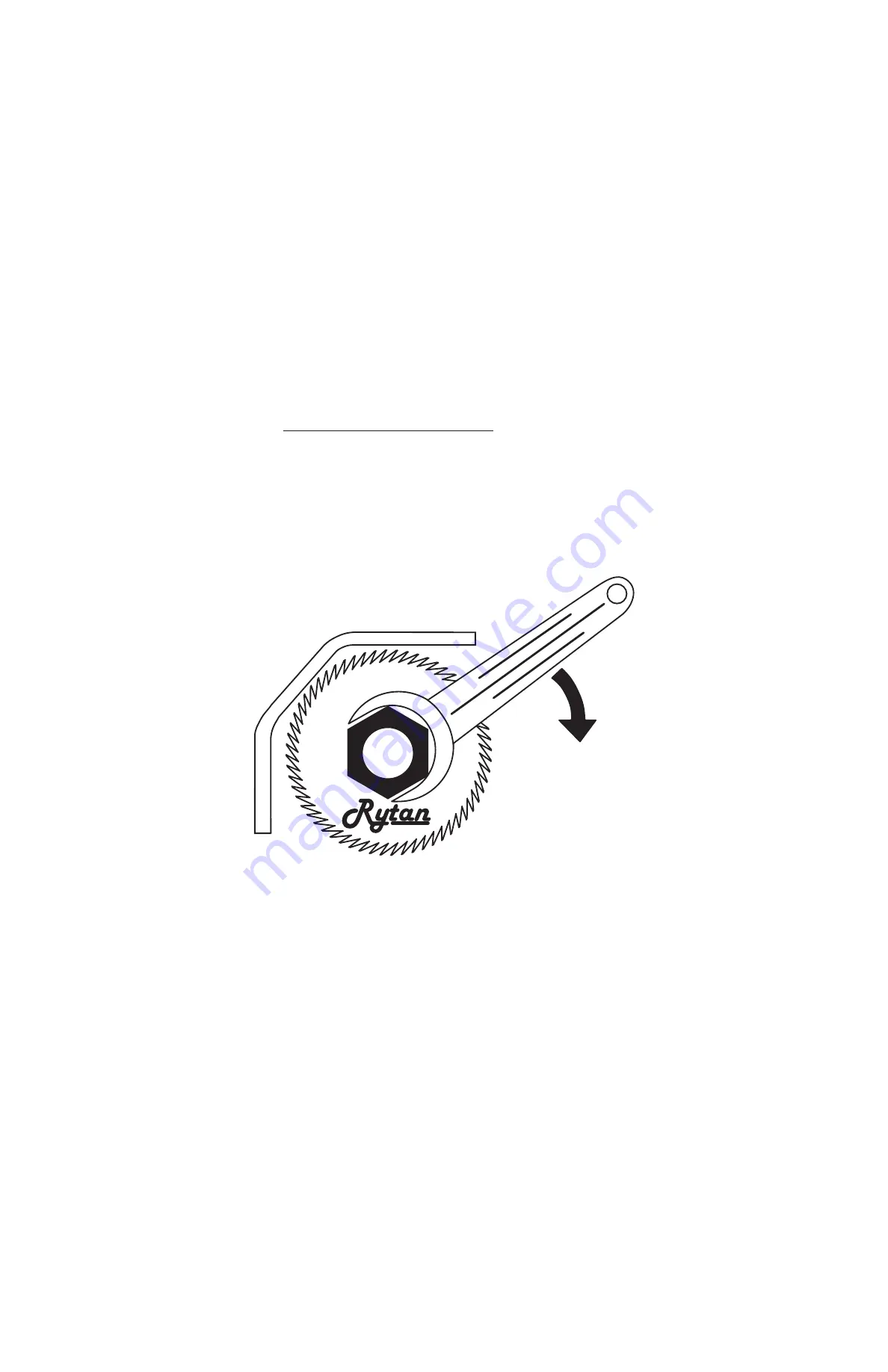

REMOVING/REPLACING THE CUTTER

REMOVING THE CUTTER

The cutter wheel is secured to the cutter shaft with a

LEFT-HAND NUT.

You must turn the nut to the

RIGHT

(facing the cutter wheel) to remove it.

11

RY

200

30 CUTTE

R

I N C O R P O R A T E D

UNDO

LEFT-HAND THREAD

FIG. 13