X - MAIN TE NANCE

Motor Maintenance

All motors use prelubricated sealed bearings; no further

lubrication is necessary.

Mechanical Inspection

Make visual inspection of dampers, linkage assemblies

and ERV rotating bearings during routine maintenance.

Filters should be checked periodically and cleaned when

necessary. Filter is located in fresh air hoods.

DO NOT

replace permanent filters with throwaway type filters.

Belt Alignment

Proper alignment is essential to maintain long V-Belt life.

Belt alignment should be checked every time belt

maintenance is performed, each time the belt is replaced,

and whenever sheaves are removed or installed.

Belt Installation

Always move the drive unit forward so the belt can be

easily slipped into the groove without forcing them. Never

force the belt into a sheave with a screw driver or wedge.

You will damage the fabric and break the cords. It is

recommended that the pulley center distances be offset by

¾" for proper length. This will allow the motor assembly to

slide forward to remove belt and backward for belt tension.

Belt Tension

Measure the span length (center distance between pulleys

when belt is snug). Mark center of span, then apply a force

(6 to 9 Lbs on new belts) perpendicular to the span large

enough to deflect the belt

1

64

"

for every inch in span length.

Energy Recovery Wheel Maintenance

Eight pie-shaped ERW segments, are seated on stops

between the segment retainer which pivots on the wheel

rim and secured to the hub and rim of wheel. Annual

inspection of the self cleaning wheel is recommended.

With power disconnected, remove ERV access panels

(rear) and unplug [J150 and P150]

(Refer to wiring

diagrams in this instruction manual).

Remove segment

and wash with water and/or mild detergent.

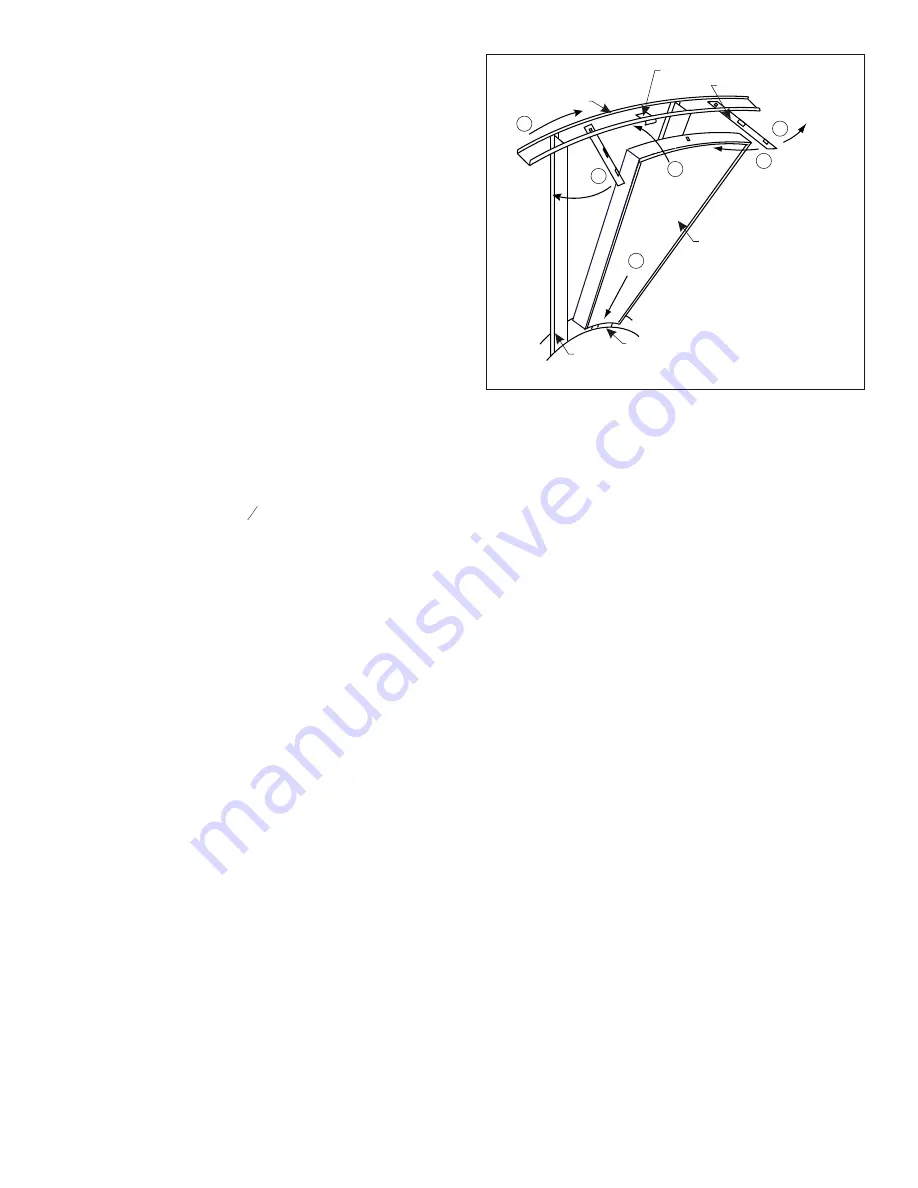

To install wheel segments follow steps A through E .

See

Figure 5.

Reverse procedure for segment removal.

A. Unlock two segment retainers (one on each side of the

selected segment opening.

B. With the embedded stiffener facing the motor side,

insert the nose of the segment between the hub plates.

C. Holding segment by the two outer corners, press the

segment towards the center of the wheel and inwards

against the spoke flanges. If hand pressure does not

fully seat the segment, insert the flat tip of a screw

driver between the wheel rim and outer corners of the

segment and apply downward force while guiding the

segment into place.

D. Close and latch each segment retainer under segment

retaining catch.

E. Slowly ro

tate the wheel 180

o

. In

stall the sec

ond

seg ment op po site the first for coun ter bal ance. Ro tate

the two in stalled seg ment 90

o

to bal ance the wheel

while the third seg ment is in stalled. Ro tate the wheel

180

o

again to in stall the fourth seg ment. Re peat this

se quence with the re main ing four segments.

PAGE 5

B

C

A

D

E

D

HUB

SEGMENT

SPOKE

SEGMENT RETAINER CATCH

WHEEL RIM

SEGMENT RETAINER

Figure 5

XI - WAR RANTY

RSI Manu fac tured Parts

In the event that defects in workmanship or materials

originate in any part manufactured by RSI, FOB point of

manufactured, we guarantee to repair or replace that part,

within three (3) months of the shipment date.

Other Sup plied Parts

Additionally, RSI guarantees to replace standard

components purchased new from a RSI vendor, (motors,

controls, etc.) that may be found defective, within twelve

(12) months of the installation date. The components

warranty, however, excludes service call charges and

labor cost for replacing or adjusting the defective part.

Limi ta tion of War ran ties

Misapplication, destruction, negligence or alteration

constitute the warranty and/or the components warranty of

RSI products and/or parts, null and void. This warranty is

provided in lieu of all other written, stated or implied

warranties.

Содержание RRS Rooftop Systems P28 Series

Страница 9: ...PAGE 9...

Страница 10: ...PAGE 10 PLATFORM SUPPORT RAIL TOP FILLER PANEL SIDE FILLER PANEL...