Keeping the World Flowing

11

Commissioning

WARNING: Ensure all power supplies are

isolated before removing actuator cover. Caution

is required when removing cover as motor and

heater may be hot. On actuators with single-

phase supplies the motor start capacitor may

retain a hazardous residual charge.

The ROMpak is factory set to operate 90º and is

designed to stop on limit at each end of travel, the

limits may be adjusted to suit the characteristics of the

valve. It will be necessary to remove the top cover to

expose the switch mechanism when adjusting cam.

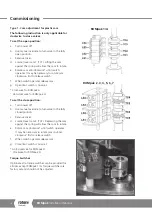

Two travel cams LS1 and LS2 are set to control the

open and close position of the valve.

Two travel cams LS3 and LS4 are set for end of travel

indication.

WARNING: Failure to check / set travel switches

could result in actuator failing to stop.

For Clockwise to Close Actuators

PCB Function Switch 7 OFF.

The travel cams are preset at the factory, when additional

adjustments are needed, follow items described below:

•

For plastic cam (as shown in picture A), refer to

‘Type 1 - Cam adjustment for plastic cam’

on

page 12 to adjust Cam.

•

For metal cam of ROMpak 1/A (as shown in

picture B), refer to

‘Type 2 - Cam adjustment

for ROMpak 1/A’

on page 13 to adjust Cam.

•

For metal cam (as shown in picture C), refer to

‘Type 3-cam adjustment for metal cam‘

on

page 14 to adjust Cam.

For ROMpak 1-7, the rotation direction of output shaft

is identical with position indicator shaft.

LS4:

Clockwise end of travel indication

LS3:

Anti-clockwise end of travel indication

LS2:

Clockwise end of travel

LS1:

Anti-clockwise end of travel

For ROMpak A, the rotation direction of output shaft

is reverse with position indicator shaft. The rotation

direction described below is the same as position

indicator shaft.

LS4:

Anti-clockwise end of travel indication

LS3:

Clockwise end of travel indication

LS2:

Anti-clockwise end of travel

LS1:

Clockwise end of travel

CAUTION: Ensure all power supplies are isolated

before removing actuator covers.

LS4

LS3

LS2

LS1

TC4

TC3

TC2

TC1

Picture A

Picture B

Picture C

LS4

LS3

LS2

LS1

TC4

TC3

TC2

TC1

LS4

LS3

LS2

LS1

TC4

TC3

TC2

TC1