8

Quick Start Operating Instructions

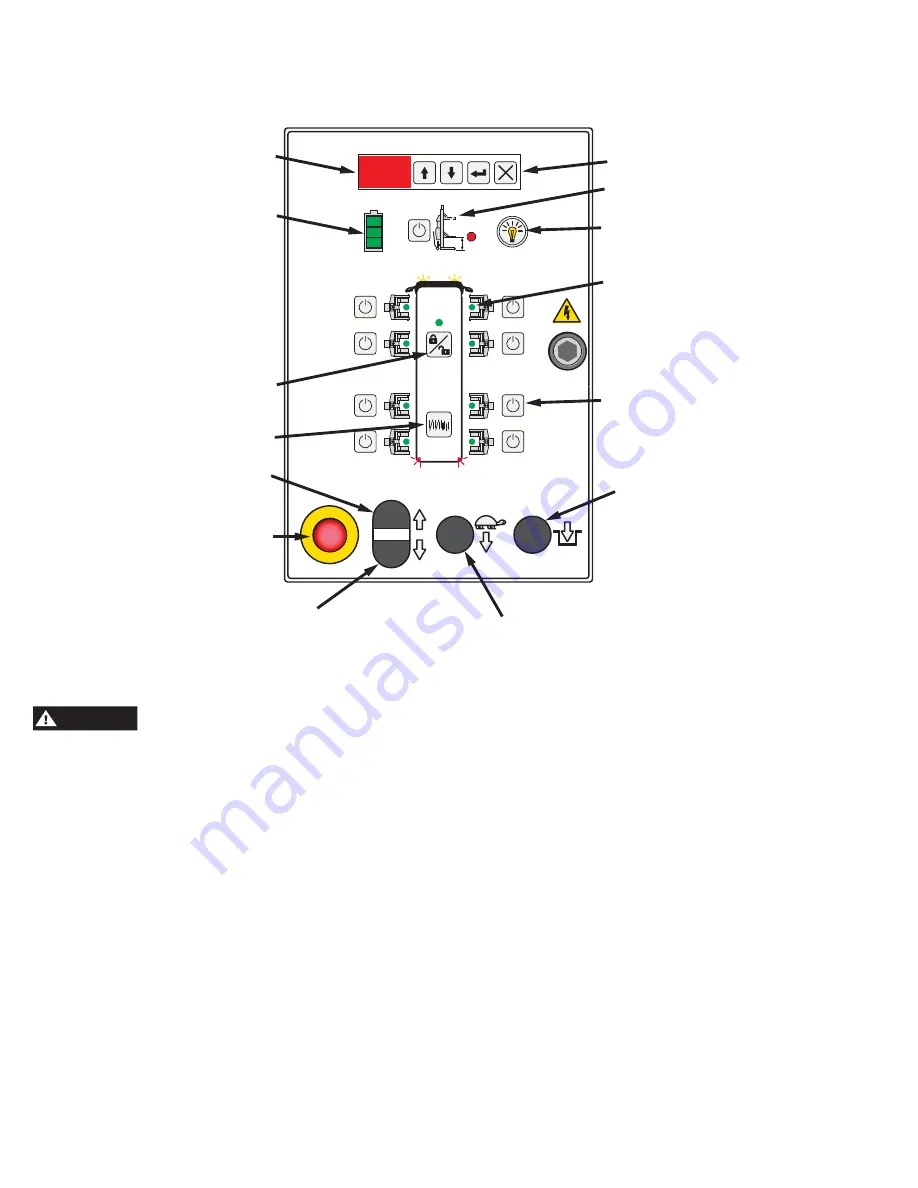

Control Panel Diagram

1. The service area must be clear of all personnel before

the vehicle is positioned.

WARNING

Locate lift on level concrete surface with a

minimum strength of 20.6 MPa.

2. Spotting: Position the vehicle in the location where it is

to be lifted.

Note: See Fig. 2 for the general arrangement of each lift

column.

3. Loading:

Position one column at a lifting wheel location. Position

so that the forks are under the tire and the unit is pushed

in as far as possible, Fig. 3. Ensure fork width is adjusted

to properly accommodate the tire/wheel size. Turn on the

Power Up Switch, Fig. 4.

4. Using the Control Panel and the bus diagram as a

reference (see graphic above), press the Activate Column

Button relative to the location where the column was just

placed. The column will show Green when activated.

5. Position next column at second wheel using loading

instructions from step 3.

6. Turn on second column. Again, using the Control Panel

and the bus diagram as a reference, press the Activate

Lift Button relative to the location of the second column.

The lift will show Green when activated. The first lift you

activated should now be flashing yellow on your control

panel.

7. Repeat step 5 thru 7 for remaining columns. When

the entire system of columns is complete, press the

System Configuration Lock/Unlock button to lock the lift

configuration for operation.

Lights on/off

(Optional Accessory)

Activate Column Buttons

(8 Total) Turns Red On

One Column When Max

Height Is Reached

Lower To Locks

Height Limit Setting

Battery Charge Indicator

System Configuration

Lock/Unlock

Single/Pair/All Mode

E-Stop

Raise

Lower

Slow Lower

Yellow, Green, Red

Activation LED’s

(8 Total)

Depress To Clear

Error Codes

Data Information

Display and Buttons

Содержание HydroLift MC75

Страница 9: ...9 Fig 3 Fig 4 Fig 2 Power Up Switch...

Страница 18: ...18 HYDRAULIC SCHEMATIC...

Страница 19: ...19 NOTES...