2-21

Level Controller Overview and Installation

Check for Leaks

Check all process penetrations for leaks. Process leaks can cause death

or serious injury.

Field Wiring

(Power and Signal)

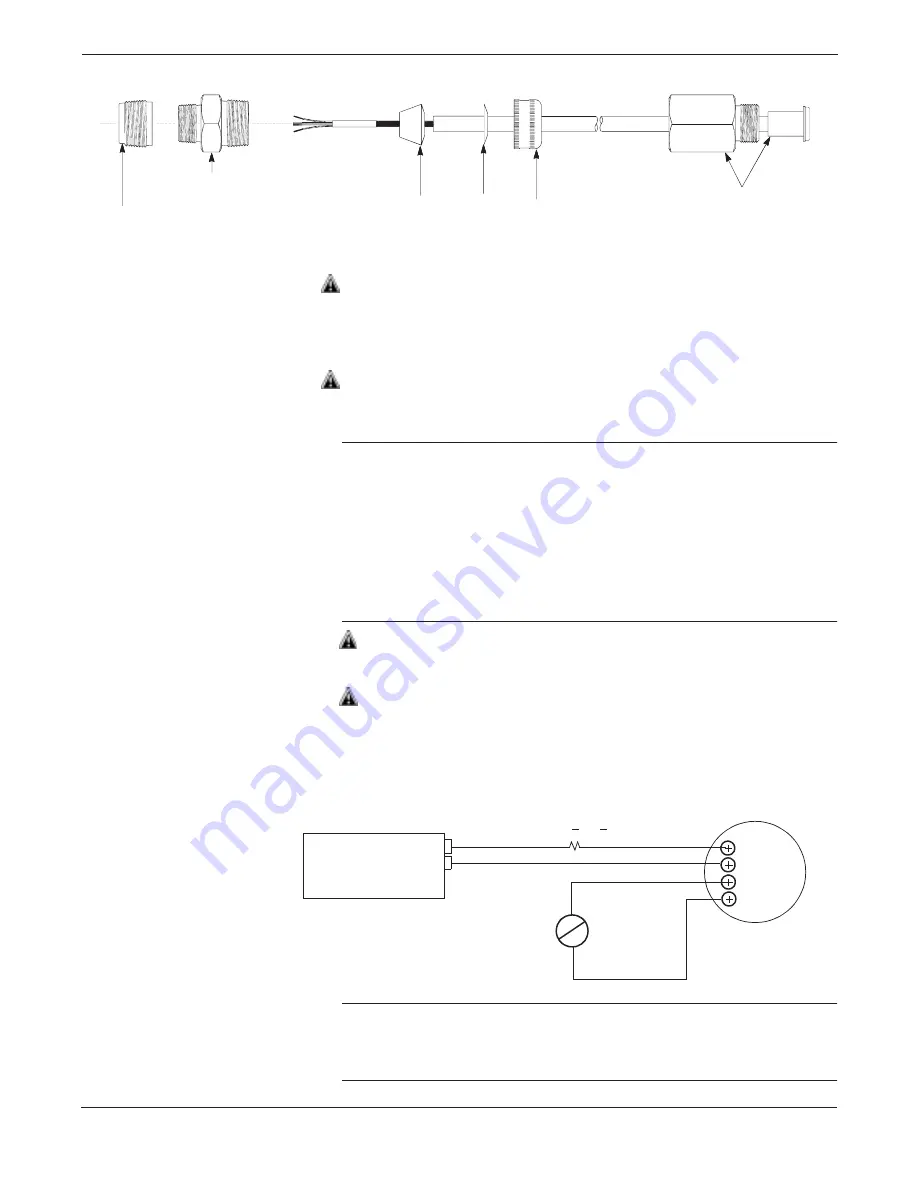

Make field wiring connections (see Figure 2-12). These connections

provide both power and signal wiring.

For

all

installations, wiring connections must be made in accordance

with local or national installation codes such as the NEC NFPA 70.

Make sure only qualified personnel perform these procedures.

NOTES

• Do not run field wiring in conduit or open trays with other power

wiring, or near heavy electrical equipment.

• Field wiring need not be shielded, but use twisted pairs for best

results.

• To ensure communication, wiring should be 24 AWG or larger

and not exceed 5,000 feet (1,500 meters).

• For connections in ambient temperatures above 140 °F (60 °C),

use wiring rated for at least 194 °F (90 °C).

1. Remove the cover on the side marked FIELD TERMINALS on the

electronics housing. Do not remove the instrument cover in

explosive atmospheres when the circuit is alive.

2. Connect the lead that originates at the positive side of the power

supply to the terminal marked “+ PWR.” Be sure to include loop

resistance. Avoid contact with leads and terminals.

3. Connect the lead that originates at the negative side of the power

supply to the terminal marked “– PWR.”

4. Connect the I/P or other actuator device to “+ OUT” and “– OUT.”

NOTE

If you are not connecting the OUT terminals to an actuator device,

you must install a jumper wire between “+ OUT” and “– OUT” for

proper operation.

Compression Fitting

Rubber Bushing

(Slide stop to edge

of armored cable)

Washer

Cap

RTD Cable Adapter

and Connector

(Connects to Model 3095 MV)

3

095

-0

020

D

01

A

¾ to ½–in. NPT Adapter

(Screws into RTD Connection Head)

1100

V

> R

L

> 250

V

+

–

I

P

FIGURE 2-12. Field

Wiring Connections.

+

–

+

–

PWR

OUT

Level

Controller

User-Provided

Power Supply

(see page 2-18)

–

+

Actuator

Device

Содержание 3095

Страница 2: ......

Страница 4: ......

Страница 8: ...viii ...

Страница 10: ...Rosemount Model 3095 Multivariable Level Controller 1 2 ...

Страница 42: ...Rosemount Model 3095 Multivariable Level Controller 3 10 ...

Страница 74: ...Rosemount Model 3095 Multivariable Level Controller 5 18 ...

Страница 98: ...Rosemount Model 3095 Multivariable Level Controller B 4 ...

Страница 100: ...Rosemount Model 3095 Multivariable Level Controller C 2 FIGURE 3 1 Explosion Proof Drawing Factory Mutual 3095 1025A01A ...

Страница 101: ...C 3 Approval Drawings FIGURE 3 1 continued 3095 1025A02A ...

Страница 102: ...Rosemount Model 3095 Multivariable Level Controller C 4 FIGURE 3 1 continued 3095 1025A03A ...

Страница 103: ...C 5 Approval Drawings FIGURE 3 2 Index of I S F M for 3095 3095 1020A01A ...

Страница 104: ...Rosemount Model 3095 Multivariable Level Controller C 6 FIGURE 3 2 continued 3095 1020A02A ...

Страница 105: ...C 7 Approval Drawings FIGURE 3 2 continued 3095 1020A03A ...

Страница 106: ...Rosemount Model 3095 Multivariable Level Controller C 8 FIGURE 3 2 continued 3095 1020A04A ...

Страница 107: ...C 9 Approval Drawings FIGURE 3 2 continued 3095 1020A05A ...

Страница 108: ...Rosemount Model 3095 Multivariable Level Controller C 10 FIGURE 3 2 continued 3095 1020A06A ...

Страница 110: ...Rosemount Model 3095 Multivariable Level Controller C 12 FIGURE 3 3 continued 3095 1024A02A ...

Страница 111: ...C 13 Approval Drawings FIGURE 3 3 continued 3095 1024A03A ...

Страница 112: ...Rosemount Model 3095 Multivariable Level Controller C 14 FIGURE 3 4 Index of I S CSA for 3095 3095 1021A01A ...

Страница 113: ...C 15 Approval Drawings FIGURE 3 4 continued 3095 1021A02A ...

Страница 114: ...Rosemount Model 3095 Multivariable Level Controller C 16 FIGURE 3 4 continued 3095 1021A03A ...