Device functions

Page 54

RES-5008

Version 2

9.27

Measures in the event of an error

System incorrectly dimensioned:

The control can function properly only if all components are matched with one another. The ROPEX application

report fulfils exactly this task and should therefore be fully implemented.

If the system is not designed according to the ROPEX application report, or if the martinal conditions change, this

can lead to bad control or even malfunctions.

If the application changes, e.g. by increase in the cycle rate or change in the heating band dimensions, the appli-

cation report must be updated accordingly. Inform us (

) and we will check what changes have to be

made to your system so that the control can work again accurately.

Check configuration:

In some cases the controller has to be operated outside of the technical specification. If this is the case, the rele-

vant information is given in the ROPEX application report. The adjustments in the control loop, for example,

by additional system components, or a modification to the controller, is described there. The necessary system

components are also listed in the parts list.

Failure to comply with these instructions can lead to operational malfunctions.

Loose contact:

The most common cause for errors is a loose contact. A loose contact can have several causes and occurs during

operation. Before initiating a thorough search for a loose contact, you should first check all connections for a good

and tight fit. Among others, weak spots can be plugs and very often clamping heads, screw connections and cable

lugs.

Requirements for looking for loose contacts:

• We recommend having an electrician to troubleshoot the machine and an employee to operate the machine.

• A continuous START signal on the temperature controller must be possible, in order to be able to carry out

continuous heating.

• It must be ensured that no dangerous movements can take place in the machine during the test, for example,

by pressing the emergency stop.

Additional information:

• In case of parallel wiring of heating elements, both current circuits must be feed through the current trans-

former, so that a loose contact can be detected.

• The calibration process (AUTOCAL) must be carried out after changes to the system (cabling, connectors,

tightening of screws, ...).

It is described below how you can locate a loose contact in your system:

1. Reset the alarm (e.g. press RESET).

2. Generate a continuous START signal on the controller at a temperature of 75 °C (corresponds to 2.5 V at

the analogue output). Make sure that the heating does not lead to a dangerous situation in the machine.

3. The operator of the machine observes the displayed or measured temperature.

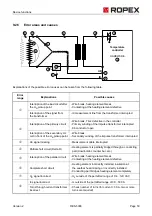

Internal device error/no line

voltage

- Hardware error (replace controller)

- Slide switch for alarm relay defective or not in correct

position

- Line voltage missing

Error

range

Explanations

Possible causes