CAUTION!

Potential hazard that may result in injury or damage to equipment.

• If the trigger is pressed a second time, the recoil of the nailer may lift the safety stand enough to allow a second nail to be

fired, even if the operator has not lifted the tip of the safety stand.

• Operate the tool with the utmost care when it is connected with the air compressor. Failure to comply may result in injury or damage to

equipment.

Cold weather operation

When operating any air-powered tool below freezing temperature:

• Verify that the compressor tanks have been properly drained prior to use.

• Keep the tool as warm as possible using any safe, convenient method.

• Place up to 6 drops of pneumatic tool oil into the tool

’

s air inlet.

• Maintain the operating level of the air pressure as recommended (see section

“

Technical Specifications

”

).

• Load the nails into the magazine (if required).

• Actuate the tool 5 to 6 times into a scrap wooden piece in order to lubricate the O-rings.

• Adjust the pressure up to the operating level (do not exceed 120 PSI) and use the tool normally.

• Relubricate the tool, as described in the maintenance section.

• Drain the compressor tanks at least once per day.

Clearing a jammed nail

To clear a jammed nail:

• Disconnect the tool from the air supply line.

• Remove the nails that are stored in the tool

’

s magazine.

• Operate the release latch and open the movable magazine for viewing the jammed nails.

• Use pliers or any appropriate tool to remove the jammed nails.

• Reload the nails into the tool magazine.

• Close the movable magazine and verify that the latch is moved to its original position.

• Reconnect the air line to the tool

’

s air inlet.

• Test fire 3 to 5 nails into a piece of scrap wood in order to ensure proper operation.

Maintenance

MAINTENANCE

REQUIRED

DESCRIPTION

TOOLS OR MATERIALS

REQUIRED

MAXIMUM SERVICE INTERVAL

Each use or every 2 hrs

Monthly As

As needed

General inspection -

free movement

Trigger, spring,

Safety mechanism

None

X

In-depth

inspection

Worn or broken

parts

X

X

Replace worn or

broken parts

X

Lubrication

See below

Pneumatic

tool oil

X

• Lubrication: If the Air-powered Brad Nailer and the compressor are not equipped with an in-line

lubrication system, place up to 6 drops of pneumatic tool oil into the air inlet before each work day or after

every 2 hours of continuous use, depending on the characteristics of the workpiece and type of fasteners

used.

• Air-operated tools must be inspected periodically and worn or broken parts must be replaced in order to

keep tools operating safely and efficiently.

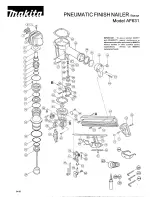

• Inspect and replace worn or damaged O-rings, seals, etc. Tighten all screws and caps frequently in order to help prevent personal

injury.

• Inspect the trigger, spring, and safety mechanism for free movement on a regular basis in order to ensure that the safety system is fully