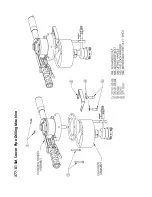

The diamond tipped pilot bit is used to cut cement, clay and reinforced

cement pipe. A pressurized water tank connected to the bearing housing is

needed to introduce water for flushing while the pilot bit is cutting. Failure to

provide water to the diamond tipped pilot bit during cutting will result in im-

mediate failure or rapid wear of the diamond tipped pilot bit.

Locate the flat on the side of the pilot then insert the blunt end of the

pilot into the main swivel housing. Align the set screw hole with the pilot drill

flat. The set screw must bear down on the pilot bit flat to ensure the pilot bit

turns while cutting the pilot bit hole.

INSTALLING THE DIAMOND TIPPED PILOT BIT

GEAR BOX

LOCKING COLLAR

BEARING HOUSING

MAIN SWIVEL

HOUSING

DIAMOND TIPPED

PILOT SET SCREW

DIAMOND TIPPED

PILOT FLAT

HOLE SAW WATER

SPRAY HOLE

DIAMOND TIPPED PILOT

WATER TANK VALVE

EYE BOLT

INSTALLING THE DIAMOND TIPPED HOLESAW

Place the Diamond Tipped holesaw on the end of the main swivel hous-

ing. The boss on the end of the main swivel housing fits into the bore in the end

of the holesaw. Next align the two 7/16” bolt holes in the holesaw with the two

3/8” threaded holes in the main swivel housing. Insert the two 3/8” x 3/4” long

hex screws from inside the holesaw shell and thread them into the main swivel

housing.

DIAMOND TIPPED HOLESAW BOLTS

DIAMOND TIPPED PILOT

Note: Do not connect the Sewer Pipe Tapping Machine to its power source until the pilot bit and

holesaw have been installed and you are ready to use the unit.

If the following key points are NOT followed this air motor will be damaged.

Please read the cover sheet and Gast motor manual before using this drive.

•

Use only clean, dry, lubricated air to drive the motor.

•

Air tool oil in the air supply is essential. Make sure air oil lubricator is filled with air tool oil.

•

Locate the air oil lubricator as close to the drive as possible.

•

Clean air is essential. Make sure your filters are clean.

•

Sand, dirt or water entering the air motor will destroy it. Make sure no contaminates enters this motor.

The Air Drive (Gast - Model # 4AM) is driven by an external compressor with the following minimum require-

ments:

Air Output:

60-75 CFM (cubic feet per minute)

Pressure Output: 80-100 p.s.i. (pounds per square inch)

*Please note that pressure less than 80 p.s.i. will severely affect the power of the air motor and its ability to complete

the cut.

*An in-line oil lubricator is essential and should be located as close as possible to the air motor. Improper lubrication

to the air motor will cause it to fail prematurely.

The Air Drive Specifications (Gast - Model # 4AM):

Horsepower:

1.75 h.p.

Speed (RPM):

3000 free @ 60 cfm and 100 psi

Weight:

30 lbs (approx)

WARNING