7

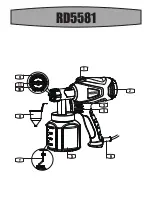

PAINT SPRAY GUN

EN

ADDITIONAL SAFETY

INSTRUCTIONS FOR YOUR SPRAY

GUN

1. Beware of high pressure at the nozzle and toxic

sprays, it can cause severe skin damage. Never

allow any part of the body to come in contact with

the spray.

2. Recommendation that the tool always be supplied

via a residual current device with a rated residual

current of 30mA or less.

3. Do not use guns for spraying flammable materials.

4. Do not clean guns with flammable solvents.

5. Warning! Be aware of any hazard presented by the

material being sprayed and consult the markings

on the container or the information supplied by

the manufacturer of the material to be sprayed.

6. Do not spray any material where the hazard is not

known.

7. Use appropriate personal protective equipment,

such as dust mask, protective clothing.

8. Do not clean guns with flammable solvents.

SYMBOL

To reduce the risk of injury, user

must read instruction manual

Double insulation

Wear ear protection

Wear eye protection

Wear dust mask

Warning

Warning: Do not direct the jet at

persons, animals and electrical

equipment.

RCM marking

ABN:

Australian Business Number. By this number,

business information such as entity type, status,

business location etc. can be found at website

http://abr.business.gov.au.

ABN of Positec Australia Pty Ltd is 14 101 682 357

TECHNICAL DATA

Voltage

220-240V~50Hz

Power consumption

350W

Nozzle size

2.5mm

Max air volume flow

500ml/min

Max viscosity

50DIN-s

Tank capacity

800ml

Spraying pressure

0.1-0.2bar

Protection class

/II

Machine weight

0.99kg

Содержание RD5581

Страница 1: ...RD5581 350W PAINT SPRAY GUN EN ...

Страница 2: ......

Страница 3: ...RD5581 5 6 1 2 11 10 9 8 7 3 4 ...

Страница 4: ...RD5581 5 15cm 25 400 11 10 C D E F G1 G2 H1 H3 H2 B1 B2 A ...

Страница 11: ......

Страница 12: ...POSITEC AUSTRALIA PTY LTD ABN 14 101 682 357 MADE IN PRC Copyright 2018 Positec All Rights Reserved ...