2

Sensor Selection

Output Characteristics

Catalog Number

Operating

Voltage

Current

Consumption

Type

Max Load

Current

Max Leakage

Current

Response

Time

LED

Cable

Pico

Power Bus

(QD required)

Red

45FVL-2LHE-A2

45FVL-2LHE-P4

45FVL-2LHE-C4

Ê

50ma or Less

PNP

Green

45FVL-3LHE-A2

45FVL-3LHE-P4

45FVL-3LHE-C4

Ê

50ma or Less

PNP

Blue

45FVL-6LHE-A2

45FVL-6LHE-P4

45FVL-6LHE-C4

Ê

12-24V DC

Output: 100ma

0 5ma

600

µ

s

White

45FVL-5LHE-A2

45FVL-5LHE-P4

45FVL-5LHE-C4

Ê

C

+/- 10%

Output: 100ma

Stability: 50ma

0.5ma

600

µ

s

Red

45FVL-2LGE-A2

45FVL-2LGE-P4

45FVL-2LGE-C4

Ê

+/ 10%

39ma or Less

NPN

Green

45FVL-3LGE-A2

45FVL-3LGE-P4

45FVL-3LGE-C4

Ê

39ma or Less

NPN

Blue

45FVL-6LGE-A2

45FVL-6LGE-P4

45FVL-6LGE-C4

Ê

White

45FVL-5LGE-A2

45FVL-5LGE-P4

45FVL-5LGE-C4

Ê

Ê

PowerBus master/3 conductor QD = 45F–A3C–A2. PowerBus slave/1 conductor QD = 45F–A1C–A2

Output and Stability Indicators

Two LEDs (green and orange) indicate a variety of conditions

to facilitate set-up and troubleshooting. The function of each is

described in the table below. Relevant output and stability

data are also shown.

LED

State

Condition

Green

OFF

ON

Unstable light signal

Stable light signal

Orange

OFF

ON

Output OFF

Output ON

Operation Indicator and Stability Indicator

Light on operation

Stable range level

On level

Off level

Unstable range level

Unstable range

Operation

Indicator

Output

Light level

Stability

Indicator

On

On

On

On

On

Unstable range

Stable range

(light interrupted)

Stable range

(light interrupted)

Stable range

(light on)

Unstable range

Dark on operation

Stable range level

Off level

On level

Unstable range level

Unstable range

Operation

Indicator

Output

Stability

Indicator

On

On

On

On

On

Unstable range

Stable range

(light interrupted)

Stable range

(light interrupted)

Stable range

(light on)

Unstable range

Light level

Operation Selector Switch

When the selector switch is in the RUN position (see following

example), the sensor will function normally, and all settings

are locked from adjustment. The SET position unlocks the

sensor’s settings, allowing the user to either adjust the sensor

manually, or use the self-teach functionality. When

adjustments are complete, return the switch to the RUN

position (settings become locked). If a manual sensitivity

adjustment is required a user can unlock this setting by

(quickly) switching from RUN to SET to RUN. The sensor will

display a flashing “S” on the LCD display, and the user can

now adjust the sensitivity setting. The sensor will automatically

return to the locked condition 10 seconds after sensitivity

adjustment is complete.

Locking

Two Adjustment Buttons

The red button is used to teach the sensor, change the

frequency and to increase the sensitivity.

The black button is used to change the operating mode,

indication mode and to decrease sensitivity.

Both buttons are inactive in the RUN mode.

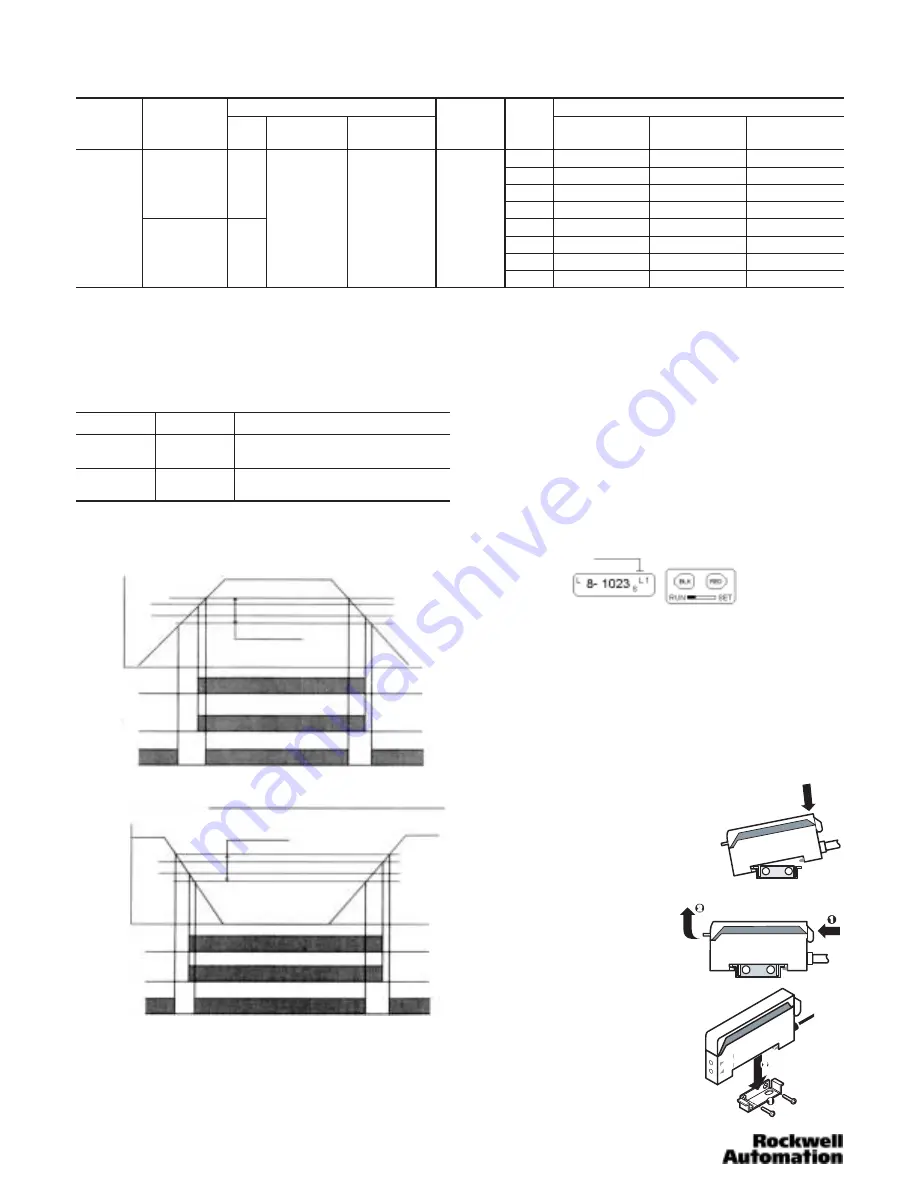

Mounting the Sensor

How to Attach Sensor to DIN Rail

Attach front hook of the photoelectric

sensor onto rail (or Mounting bracket)

and press rear end of sensor down

until unit snaps into place.

How to Detach Sensor from DIN Rail

Pushing the sensor unit forward,

pull up on the front of the sensor

until the front hook is detached.

Remove sensor.

Side Mounting Sensor with Bracket

Fasten mounting bracket assembly

using M3 screws. Tightening torque is

0.8Nm max. Attach front hook of the

photoelectric sensor onto mounting

bracket and press rear end of sensor

down until unit snaps into place.