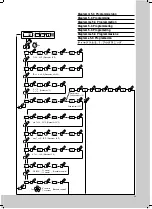

F1

Q4

Q3

T1

K1

K5

Q1

F2

Q2

K2

K1.1

K5

K2

Q1

K1

M1

M2

M4

F3

13

>T

14

~

24 V AC

>P

0 V AC

L1

L2

L3

T

S

R

3

M

1 3 5

M

3

U V

W

M

3

6

4

2

2 4 6

5

3

1

A1

A2

A1

A2

C

A

95

96

~

24 V AC

<p

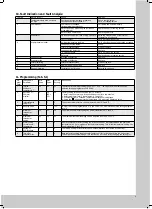

Ersatzteil-

liste

Spares

List

Liste

de pièces

détachées

Lijst

reserve-

delen

Reserv-

delslista

Lista dei

pezzi di

ricambio

Lista de

piezas de

repuesto

Bezeichnung

Description

Signification

Benaming

Beteckning

Descrizione

Descripción

1

Kompressor

Compressor

Compresseur

Compressor

Kompressor

Compressore

Compresor

5

Verflüssiger-

ventilator

Condensing valve

Soupape

du condenseur

Condensor-

ventilator

Kondensorfläkt

Ventilatore

del condensatore

Ventilador

del condensador

10

Verdampfer-

ventilator

Evaporator valve

Soupape

de l’évaporateur

Verdamper-

ventilator

Förångarfläkt

Ventilatore

dell’evaporatore

Ventilador

del evaporador

15

Versandbeutel

Dispatch bag

Pochette

d’accessoires

Zakje toebehoren

Tillbehörspåse

Sacchetto

accessori

Bolsa de

accesorios

20

Expansionsventil

Expansion valve

Soupape de

détente

Expansieventiel

Expansionsventil

Valvola

d’espansione

Válvula de

expansión

25

Filtertrockner

Filter dryer

Assècheur de filtre

Filterdroger

Filtertork

Filtro essicatore

Secador del filtro

30

Pressostat

Pressostat

Pressostat

Pressostaat

Pressostat

Pressostato

Presostato

35

Thermostat

Thermostat

Thermostat

Thermostaat

Thermostat

Termostato

Termostato

40

Microcontroller-Box Microcontroller

box

Micro-processeur

box

Microcontroller

E-box

Microkontroll box

Box Microcontroller

Carcasa

microcontrolador

45

Lamellengitter 2

Louvred grille 2

Grille à lamelles 2

Rooster 2

Lamellgitter 2

Griglia a lamelle 2

Rejilla 2

46

Lamellengitter 1

Louvred grille 1

Grille à lamelles 1

Rooster 1

Lamellgitter 1

Griglia a lamelle 1

Rejilla 1

50

Abdeckblende

Infill panel

Couvercle

Afdekplaat

Täckplåt

Copertura cieca

Pantalla cubierta

55

Anzeigeplatine

Display PCB

Platine d’indication

Displayprint

Displaykort

Scheda di

comando

Pletina de

indicación

60

Displayaufnahme

Display support

Support de platine

Display

Displayram

Alloggiamento

Display

Display

65

Folientastatur

Membrane

keyboard

Clavier à

effleurement

Folietoetsenbord

Folie tryckkrappar

Tastiera a

membrana

Teclado de

membrana

66

Abdeckfolie

Covering

membrane

Feuille de

recouvrement

Afdekfolie

Täckfolie

Lamina di

copertura

Lámina cubierta

70

Temperaturfühler,

Vereisung

Icing

sensor

Sonde de

givrage

Aanwijzings-

sensor

Nedisnings-

givare

Sonda

riferimento

Sensor

referencial

71

Temperaturfühler

Temperature

sensor

Sonde de

température

Temperatuur-

sensor

Temperaturgivare

Sonda di

temperatura

Sonda térmica

75

Haube

Cover

Couvercle

Afdekkap

Huv

Calotta

Capucha

80

Transformator

Transformer

Transformateur

Trafo

Trafo

Trasformatore

Transformador

85

Tropfenabscheider

Mist collector

Paregouttes

Lekbok

Kondensvatten

anskiljare

Separatore gocce

Colector de gotas

90

Verdampfer

Evaporator

Evaporateur

Verdamper

Kondensor

Evaporatore

Evaporador

100

Verflüssiger

Condenser

Condenseur

Condensor

Förångar

Condensatore

Condensador

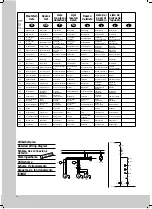

D

E

J

GB

NL

I

F

S

36

Position

Item

Pos.

Pos.

Pos.

Pos.

Posición

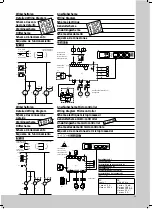

Wirkschaltplan

Detailed Wiring Diagram

Schéma des connexions

détaillé

Werkingsschema

Driftschema

Schema d’allacciamento

Esquema de funcionamiento

SK 3260.140