- 22 -

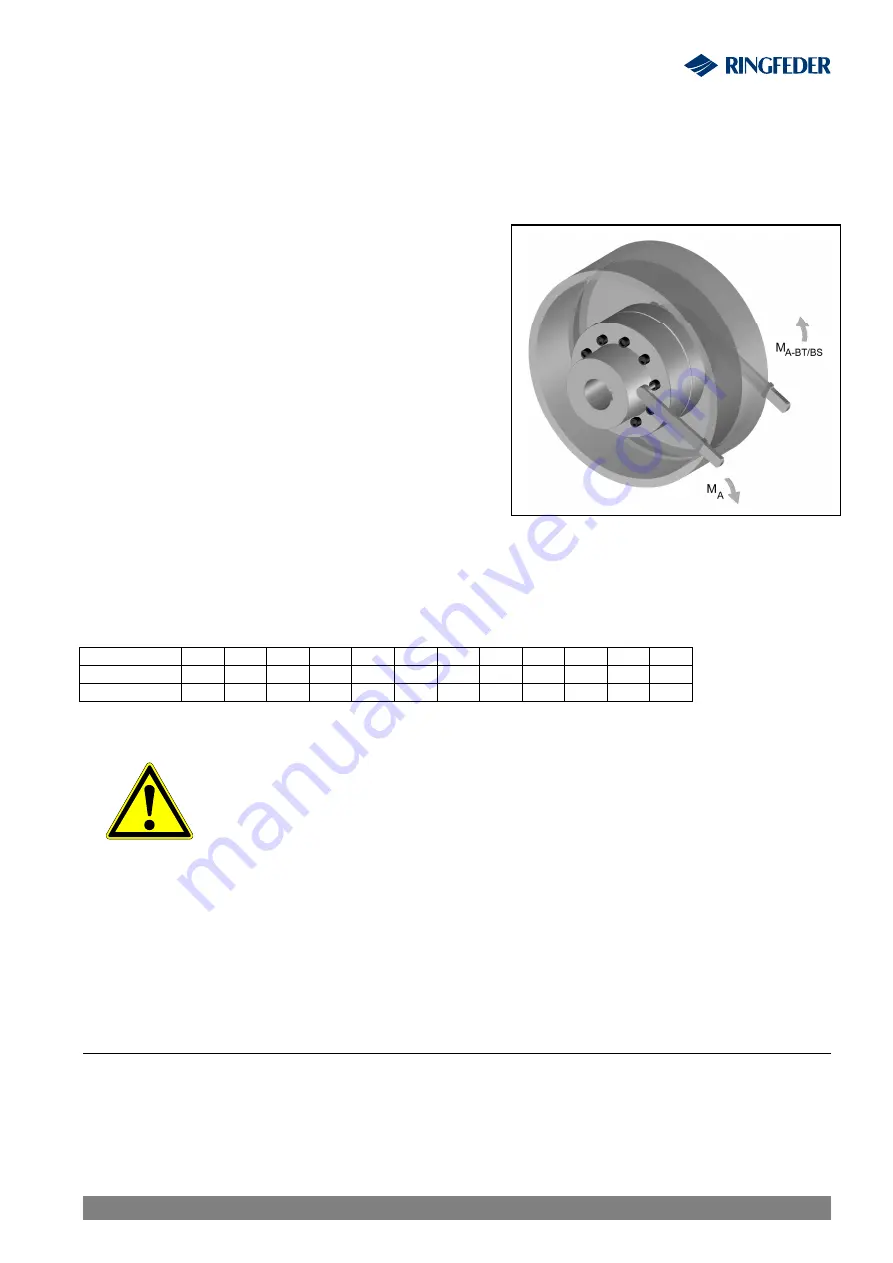

Fig. 14

10.4 Assembly brake drum/disk

Attention!

The contact surfaces of coupling hub and brake drum/disk must be clean, dry and free

of grease. Balanced parts are match marked to each other.

·

Place the brake drum/disk in their proper

position as marked. Make sure that the parts do

not get canted at the centering seats when join-

ing them.

·

Slightly tighten the screws.

·

Tighten the screwed connections of brake

drum/disk to the proper torque M

A

specified in

table 10.

·

Check the alignment of the coupling according

to the instructions given in chapter 8 ‘Coupling

Alignment“.

Table 10

Tightening torques M

A-

for brake drum/disk threaded joints:

Size

112 128 148 168 194 214 240 265 295 330 370 415

DIN 933- 8.8

8

8

10

10

12

12

12

16

16

16

16

16

M

A-BS

[Nm]

25

25

49

49

85

85

85 210 210 210 210 210

Warning!

§

Before commissioning the plant install all protective devices

against unintentional touching of free rotating parts.

§

To avoid sparks coverings in stainless steel should be used.

§

The coverings must fulfil at least the protection type IP2X.

§

The covering is to be so designed that it does not deposit dust

onto the coupling parts.

§

The covering must not touch the coupling or influence it in its

functioning.

When using accessories and spare parts which were not originally manufactured by

RINGFEDER POWER TRANSMISSION, no liability or guarantee for any damages

will be accepted.

11 Waste Disposal

The waste disposal has to occur according to the specific regulations of the respective user

country.

RINGFEDER

®

TNM GBT, TNM GTW

BAWN 006-

GBR

-1