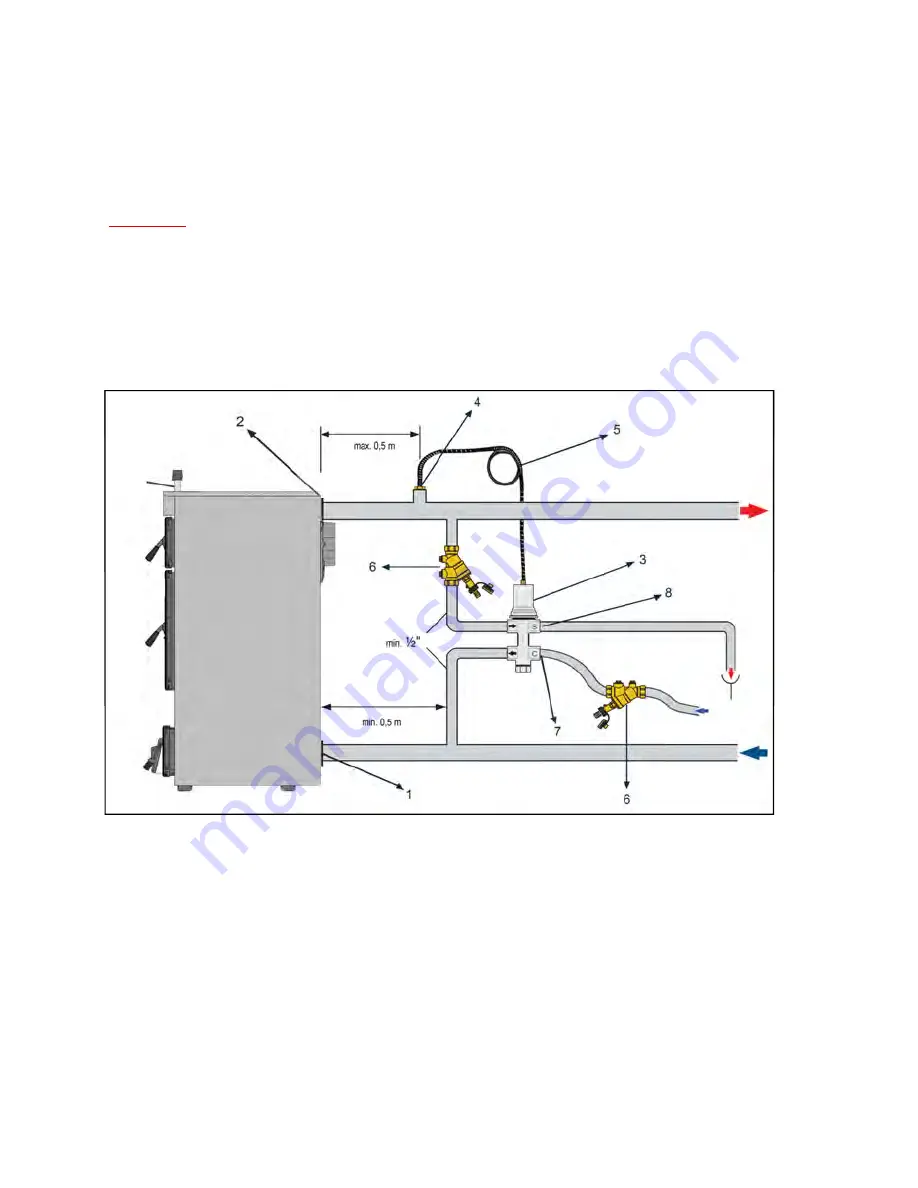

Temperature safety valve

The S.MAX boilers are equipped with a safety valve (Fig.10) which ensures dissipation of excessive heat without

additional device and supply of external energy in such a way that the maximum permissible boiler temperatu-

re of 95°C is not exceeded. A temperature safety valve must be connected to the inlet - outlet connections of

th b il

the boiler.

Please note

• It is not permissible to reverse the flows, the indications for inlet and drain shown on the valve must be

followed.

• Maximum temperature of the input water for temperature safety valve is 15 °C and minimum water pressure

Maximum temperature of the input water for temperature safety valve is 15 C and minimum water pressure

is 2 bar.

• Functionality of safety device ( caleffi 544 ) must be checked or inspected by authorized person once in a

year.

fig. 10

1. Heating water inlet

2. Heating water outlet

3. Safety device ( caleffi 544 ) - max. working pressure : 6 bar

4. Safety device probe ½”

5. Safety device probe capillary

6. Filter

7. Cooling water inlet ½”

8. Safety heat outlet ( drain) ½”

10

Содержание S.MAX Series

Страница 1: ...S MAX SERIES SOLID FUEL BOILER S MAX SERIES SOLID FUEL BOILER 0 S MAX REV 01 2010 0036 0036...

Страница 4: ...Boiler dimensions Boiler packaging dimensions 3...

Страница 5: ...Technical parameters 4...

Страница 17: ...fig 12 fig 13 fig 14 fig 15 16...

Страница 22: ...SMAX boiler parts fi 18 fig 18 fig 19 21...

Страница 23: ...Spare parts list p p fig 20 22...