Technical description of the burner

9

2916050

GB

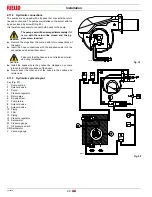

3.7

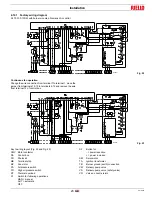

Burner description

1

Ignition electrodes

2

Combustion head

3

Screw for combustion head adjustment

4

Screw for fixing fan to flange

5

Pressure gauge for pressure on nozzle return

6

Pump

7

Non-drip nozzle holder

8

Air damper

9

Fan pressure test point

10 Boiler mounting flange

11 Flame stability disk

12 Servomotor, provides adjustment of fuel delivery regulator

and of air damper.

When the burner is not operating the air damper is fully closed

in order to reduce to a minimum heat dispersion from the

boiler.

13 Slide bars for opening the burner and inspecting the combus-

tion head

14 Photocell (cad cell)

15 High oil pressure switch

16 Extensions for slide bars 14) (with kit)

17 Ignition transformer

18 Motor contactor and thermal overload with reset button

19 Power switch for different operations: automatic - manual - off

Button for: power increase - power reduction

20 Valve assembly with pressure regulator on nozzle return

21 Terminal strip

22 Knockouts for electrical connections by installer

23 Flame safeguard with lock-out pilot light and lock-out reset

button

24 Flame inspection window

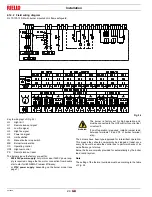

Two types of burner failure may occur:

Flame safeguard lock-out

: if the flame relay 23)(Fig. 3)

pushbutton lights up, it indicates that the burner is in lock-out.

To reset, press the pushbutton.

Motor trip

: release by pressing the pushbutton on thermal

overload 18)(Fig. 3).

Fig. 3

D2349