RECyClING AND DISPOSAl

14

2.7

Troubleshooting

Power failure

If unit display does not turn on after you press

on remote

control, and equipment does not turn on, ensure that:

—

equipment power plug, if any, is properly plugged

—

system main switch is set to “ON”

—

remote control batteries are well charged

9

If necessary, contact

R

Technical Support Service.

The climate control system does not sufficiently cool down or

warm up the air

Check that:

—

the mesh filter is clean

—

doors or windows leading outdoors are closed

—

Unit air flow is free from obstructions

—

set temperature is the one actually required

9

If necessary, contact

R

Technical Support Service.

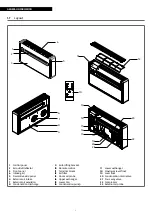

faults displayed on the control panel

Faults are communicated through a code on the unit’s control

panel.

1

Control panel

1

To restore operating conditions:

—

set the main switch to “Off”

—

allow 10 minutes

—

set main switch back to “ON”

—

press

on remote control

If the climate control system resumes normal operation, it means

that shutdown was due to an erratic condition.

9

If the fault occurs again, an accurate check of the device

components is required. Contact

R

Technical Support

Service.

fault codes

Code

Description

Remarks

E1

Room probe fault

Cooling, Dehumidifying

and Heating modes

remain active

The adjustment only

monitors the internal

battery antifreeze

E2

Upper exchanger probe

fault

The unit resets after

problem resolution

E3

Outdoor air temperature

probe fault

E4

Lower exchanger probe

fault

Cooling, Dehumidifying

and Heating modes

remain active

Defrosting operates at

fixed time cycles

E5

Upper fan motor fault

The unit resets after

problem resolution

E6

Lower fan motor fault

E7

Communication error

between unit and control

panel

Communication error

between electronic

boards

E8

Compressor outlet probe

fault

CP

Presence contact open

The unit resets upon

contact closure

OF

Maximum level float

triggering

The unit resets after

problem resolution

9

In case of simultaneous failure of two probes, the unit turns

off and resets after the resolution of the problem.

faults requiring intervention of the Technical Support Service

If any of these faults occurs:

—

the power cable is too hot or damaged

—

a strange noise is heard during operation

—

either the cut-out, a fuse or grounding switch is tripping

all the time

—

a switch or a button is not operating properly

—

user smells burnt

—

water leakage from the unit

An accurate inspection of equipment components is required.

—

set the main switch to “Off”

—

immediately contact

R

Technical Support Service.

Normal noise during operation

During normal operation, the equipment may make particular

noise linked to settling, expansion of the materials or refrigerant

flow. This type of noise should not be considered a fault:

—

ticking due to expansion or shrinking of materials upon

temperature changes

—

hiss due to refrigerant cycle inversion when changing op-

erating mode and toggling between Cooling and Heating

or during defrost

—

swish similar to water flowing due to the refrigerant gas

flowing in the unit

3

DISPOSAL

Packing materials must be disposed of separately, in order to be

recovered and recycled. Equipment at end of life and flat bat-

teries must be disposed of as required by prevailing law and