8

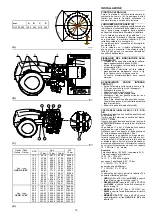

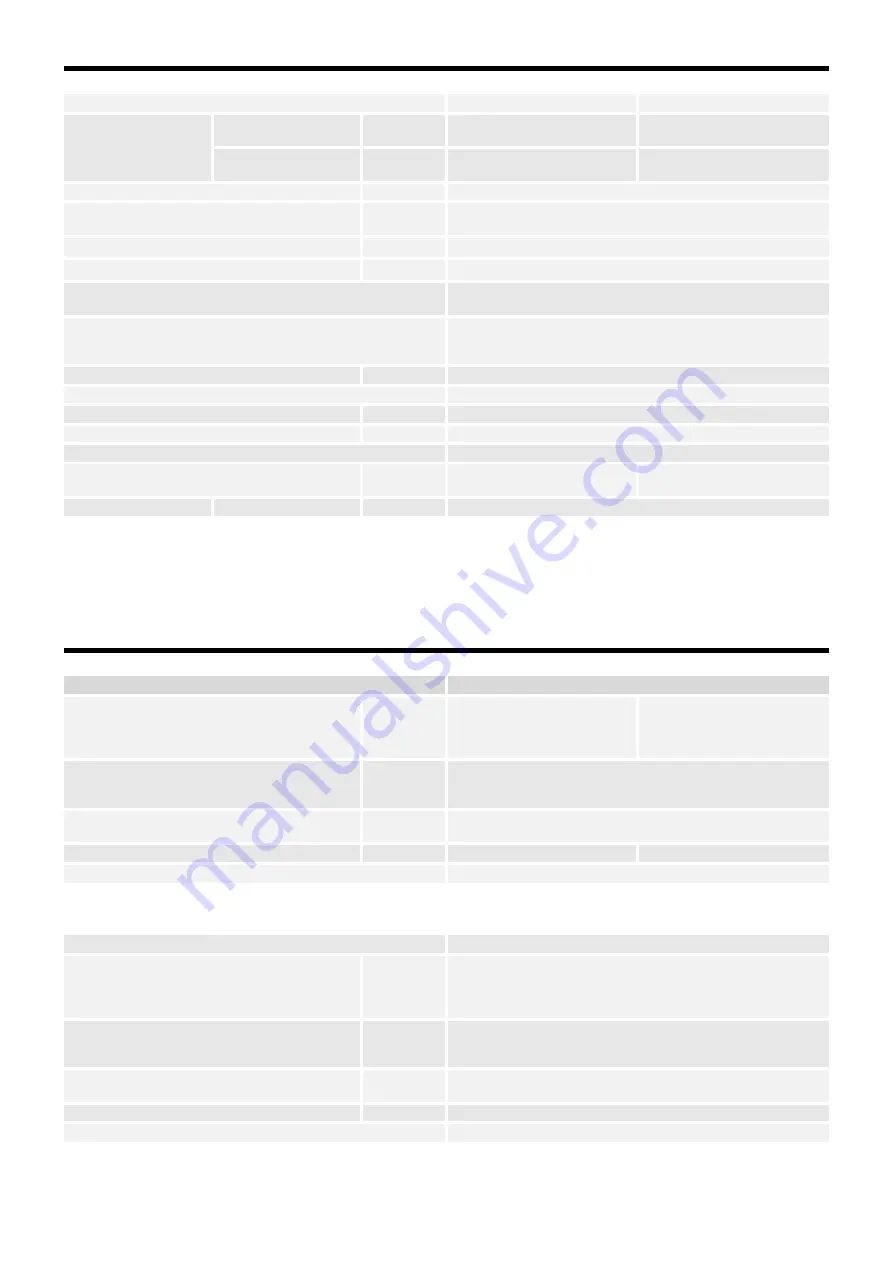

TECHNICAL DATA

(1)

Reference conditions: Ambient temperature 20°C - Barometric pressure 1000 mbar - Altitude 100 m a.s.l.

(2)

Pressure at pressure switch test point 20)(A)p.12 with zero pressure in the combustion chamber and maximum burner output.

(3)

Sound pressure measured in manufacturer's combustion laboratory, with burner operating on test boiler and at maximum rated output. The

sound power is measured with the “Free Field” method, as per EN 15036, and according to an “Accuracy: Category 3” measuring accuracy, as

set out in EN ISO 3746.

ELECTRICAL DATA

Model

RL 300/B MZ

RL 400/B MZ

Type

966 T

967 T

Output

(1)

Delivery

(1)

2nd stage

(min - max)

kW

kg/h

1250 ÷ 3550

105 ÷ 301

2000 ÷ 4450

169 ÷ 378

1st stage

(min)

kW

kg/h

600

50

1000

84

Fuel

LIGHT OIL

- net calorific value

kWh/kg

Mcal/kg

11.8

10.2 (10.200 kcal/kg)

- density

kg/dm

3

0.82 - 0.85

- viscosity at 20 °C

mm

2

/s

max 6 (1.5 °E - 6 cSt)

Operation

- Intermittent (min. 1 stop in 24 hours)

- Two-stage (high and low flame) and single-stage (all - nothing)

Pump

delivery at 20 bar (kg/h)

pressure range (bar)

fuel temperatur (°C)

380

7 - 40

140

Nozzles

number

2

Standard applications

Boilers: water, steam, diathermic oil

Ambient temperatur

°C

0 - 40

Combustion air temperature

°C max

60

Conformity to directives

2014/30/UE - 2014/35/UE - 2006/42/EC

Noise levels

(3)

Sound pressure

Sound power

dBA

83

94

85

96

Approval

class 2 (EN 267)

CE

Model

RL 300/B MZ

RL 400/B MZ

Electrical supply

3N ~ 400V +/-10% 50 Hz

Fan motor IE2

rpm

V

kW

A

2900

230/400

4.5

15/8.7

2900

400/690

7.5

13.8/8

Pump motor

V

kW

A

220/380

1.1

4.5 - 2.6

Ignition transformer

V1 - V2

I1 - I2

230 V - 2 x 5 kV

1.9 A - 35 mA

Electrical power consumption

kW max

7

10.6

Electrical protection

IP 54

Model

RL 400/B MZ

Electrical supply

3N ~ 400V +/-10% 50 Hz

Fan motor IE3

rpm

V

kW

A

2920

400/690

7.5

14/8.1

Pump motor

V

kW

A

220/380

1.1

4.5 - 2.6

Ignition transformer

V1 - V2

I1 - I2

230 V - 2 x 5 kV

1.9 A - 35 mA

Electrical power consumption

kW max

10.6

Electrical protection

IP 54

Содержание 966 T

Страница 43: ...43 0 1 2 30 0 0 1 2 30 0 1 2 2 4 4 0 4 0 5 4 6 4 0 4 0 0 4 4 4 4 4 74 7 7 4 4 0 5 4 0 0 0 0 0 0 0 RL 300 B MZ...

Страница 45: ...45 RL 300 B MZ...

Страница 46: ...46 RL 400 B MZ...

Страница 47: ...47...

Страница 48: ...48 RL 300 B MZ...

Страница 49: ...49 0 1 1 1 2 3 2 RL 400 B MZ...

Страница 50: ...50 01123 0 3 112 01453 6 7 0 3 8 9 0 3 112 01453 6 7 8 9 8 8 9 8 9 76 76 A...

Страница 53: ......

Страница 54: ......

Страница 55: ......