6

r

RTS 3S

steel boilers are high efficiency triple flue

pass boilers for central heating systems. When com-

bined with a storage cylinder, they can also be used to

produce domestic hot water.

r

RTS 3S

boilers are monobloc boilers with pressur-

ised combustion. The flame from the burner first enters

the furnace (1st flue pass). Via an opening at the other

end of the furnace, the combustion gases then enter a

duct that takes them back towards the front of the boiler

(2nd flue pass).

This separation between the combustion gas return duct

and the furnace makes a major contribution to reducing

Nox emissions. Combustion gases remaining in the high

temperatures of the furnace is one of the main reasons

for the formation of NOx emissions.

At the front of the boiler, the combustion gases pass

through a recess in the door insulation and exit through

the tube bundle (3rd flue pass).

In the tube bundle, turbulators force the combustion

gases into a vortex-like path that improves the efficiency

of convection heat exchange.

This system achieves maximum heat absorption without

risking damage through thermal stress.

Once out of the tube bundle, the flue gases pas through

a chamber at the rear of the boiler, and into the vent flue.

Their special design (with tube bundle over the combus-

tion chamber) makes these boilers far narrower than

conventional pressurised boilers and therefore easier to

install in boiler rooms with narrow doors or where space

is limited.

The burner is installed in a hinged door to permit the

adjustment and servicing of both boiler and burner with-

out having to remove the burner.

The boiler body is thermally insulated by high efficiency

mineral wool insulation that reduces heat loss to an

extremely low level.

The boiler casing is made from pre-painted panels lined

with mineral wool insulation.

Max. permissible return temperature with a gas burner:

50°C.

Max. permissible return temperature with a fuel oil

burner: 37°C.

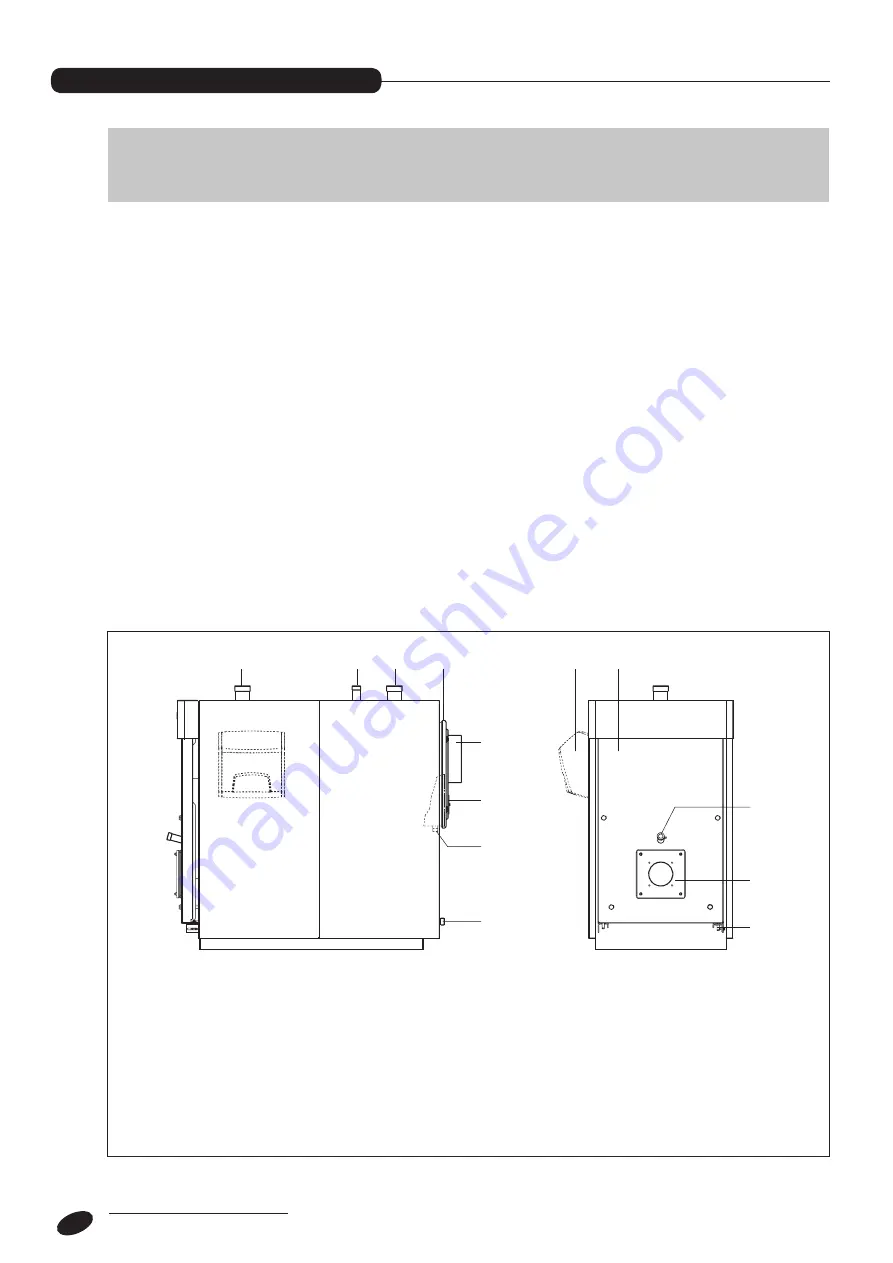

1

2

3

4

5

6

7

8

9

10

13

11

12

1 - Door hinge

2 - Central heating return

3 - Central heating flow

4 - Safety device fitting

5 - Flue gas box

6 - Flue gas exhaust

7 - Access door for cleaning the flue gas box

8 - Condensate drain

9 - Boiler drain

10 - Door

11 - Flame inspection window

12 - Burner plate

13 - Control panel

Product description

PRODUCT DESCRIPTION

MODELS UP TO 400 KW USED WITH FUEL OIL BURNERS CONFORM TO THE ENERGY-RELATED PRODUCTS

DIRECTIVE 2009/125/EC AND TO THE EU DELEGATED REGULATION 813/2013

GENERAL