0ML190480RUENUC

page 8 / 24

SECTION

3

BATTERY CABINET SETUP

This section describes:

Floor load-carrying capacity and clearances

Handling the cabinet

Equipment inspection

FLOOR LOAD-CARRYING CAPACITY

When planning the commissioning, consider the battery cabinet weight for floor where it will be placed. The

load-carrying capacity of the installation surface must be adequate for point and distributed loading. The

approximate weights are shown in the following table.

Table

2

‐

Floor

Load

‐

carrying

capacity

Battery Cabinet with batteries 100Ah

Maximum Weight

Point Loading

1750kg (3859 lbs)

A

3.8kg/cm

2

(54lb/in

2

)

B

1.3kg/cm

2

(12lb/in

2

)

Battery Cabinet with batteries 55Ah

Maximum Weight

Point Loading

1150kg (2536 lbs)

A

2.5kg/cm

2

(36lb/in

2

)

B

0.8kg/cm

2

(11lb/in

2

)

Battery Cabinet without batteries

Maximum Weight

300kg (662 lbs)

CLEARANCE

S

The following clearances are recommended for the Battery Cabinet.

Front of Cabinet

150 cm (59”) working space

Back of Cabinet

15.2 cm (6”)

HANDLING THE CABINET (unloading and transporting)

The cabinet can be shipped including the batteries installed inside or without batteries.

On table 2 are reported the weights of cabinets, with and without battery blocks installed.

Unloading and transporting of cabinet must be carried out with appropriate forklift. See fig. 3 for the correct

way to lift the cabinet.

CAUTION

to move the cabinet make sure to use a forklift with appropriate characteristics,

rated for the cabinet weight.

Unloading the cabinet requires at least two people to safely remove the cabinet from the

pallet

To remove the battery cabinet from ship pallet:

1) Make sure the path traveled has sufficient support for the combined weight of the forklift and the

battery cabinet.

Содержание MASTER HP

Страница 1: ...UNINTERRUPTIBLE POWER SUPPLY MASTER HP UL 55 100Ah BATTERY CABINET User Manual ...

Страница 2: ...0ML190480RUENUC page 2 24 RPS SpA Viale Europa 7 37045 Legnago VR Italy www riello ups com ...

Страница 17: ...0ML190480RUENUC page 17 24 ...

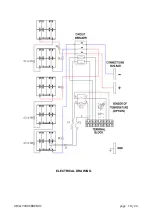

Страница 18: ...0ML190480RUENUC page 18 24 ELECTRICAL DRAWING ...

Страница 20: ...0ML190480RUENUC page 20 24 ...

Страница 21: ...0ML190480RUENUC page 21 24 ...

Страница 23: ...0ML190480RUENUC page 23 24 Fig 14 battery cabinet terminal block detail ...

Страница 24: ...0ML190480RUENUC page 24 24 Fig 15 Connections diagram of auxiliary signals ...