6

INSTALLATION

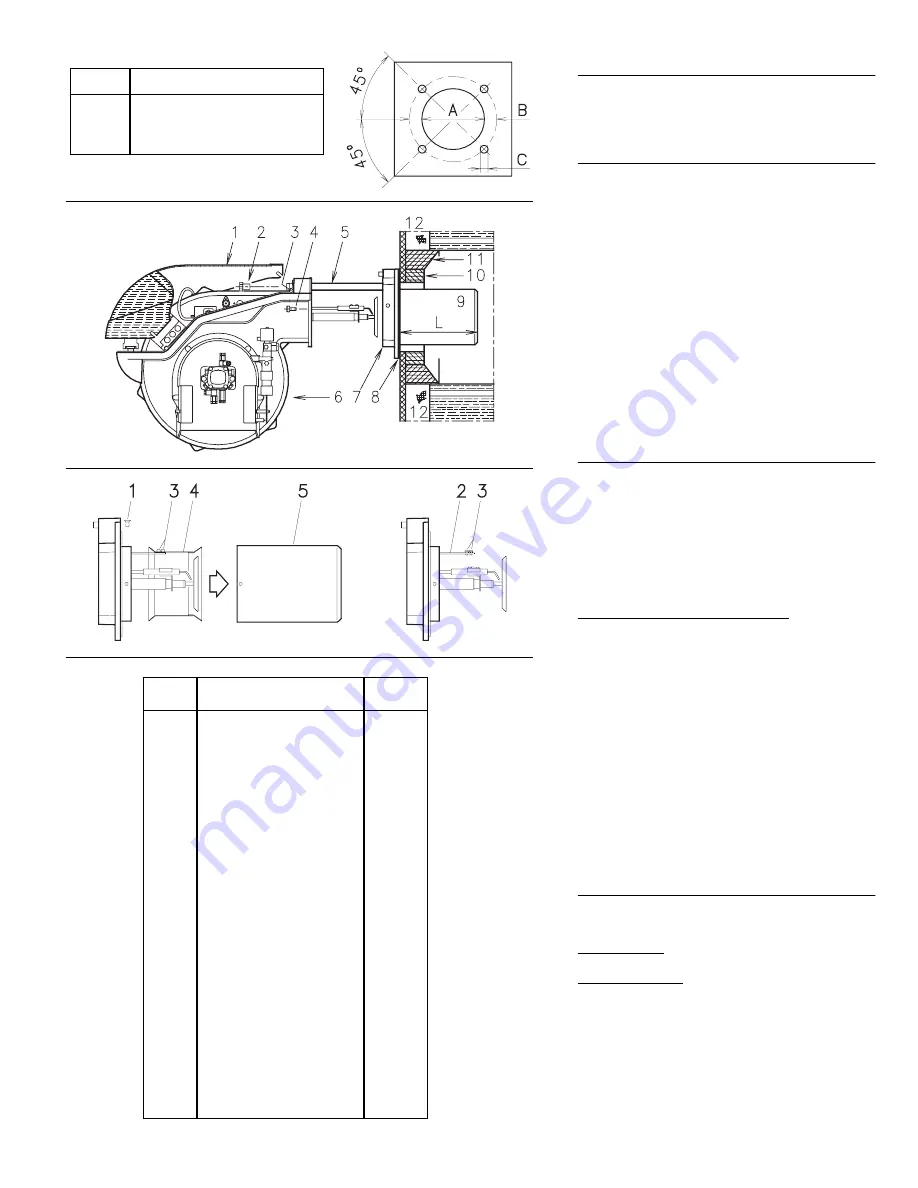

BOILER PLATE (A)

Drill the combustion chamber mounting plate as

shown in (A). The position of the threaded holes can

be marked using the burner gasket supplied with the

burner.

BLAST TUBE LENGTH (B)

The length of the blast tube must be selected accord-

ing to the indications provided by the manufacturer of

the boiler, and it must be greater than the thickness of

the boiler door complete with its insulation. The range

of lengths available, L (inch), is as follows:

Blast tube 9):

RL 70

RL 100

RL 130

• short

9

27/32

9

27/32

9

27/32

• long (with the kit)

15

5/32

15

5/32

15

5/32

For boilers with front flue passes 12) or flame inversion

chambers, protective insulation material 10) must be

inserted between the boiler's refractory 11) and the

blast tube 9).

This protective insulation must not compromise the ex-

traction of the blast tube.

For boilers having a water-cooled front, the insulation

10)-11)(B) is not required unless it is required by the

boiler manufacturer.

SECURING THE BURNER TO THE BOILER (B)

Disassemble the blast tube 9) from the burner 6) by

proceeding as follows:

- Loosen the four screws 3) and remove the cover 1).

- Remove the screws 2) from the two slide bars 5).

- Remove the two screws 4) fixing the burner 6) to the

flange 5).

- Withdraw the blast tube 9) complete with flange 7)

and slide bars 5).

COMBUSTION HEAD CALIBRATION

At this point check, for model RL 130, whether the

maximum delivery of the burner in high fire operation

is contained in area B or in area C of the firing rate.

See page 5.

If it is in area B then no operation is required.

If, on the other hand, it is in area C:

- Unscrew the screws 1)(C) and disassemble the

blast tube 5).

- Unscrew the screws 3) and remove the shutter 4).

- Tighten the screws 3) on the rod 2).

- Now refit the blast tube 5) and the screws 1).

Once this operation has been carried out (if required),

secure flange 7)(B) to the boiler plate inserting the

supplied gasket 8). Use the 4 screws provided after

having protected the thread with an antiseize product

(high-temperature grease, compounds, graphite). The

burner-boiler seal must be airtight.

CHOICE OF NOZZLES FOR LOW AND HIGH FIRE

Both nozzles must be chosen from among those listed

in Table (D).

The first nozzle determines the delivery of the burner

at low fire.

The second nozzle works in combination with the low

fire nozzle to determine the delivery of the burner at

high fire.

The total deliveries of low and high fire must be con-

tained within the value range indicated on page 3.

Use nozzles with a 60° spray angle at the recommend-

ed pressure of 174 PSI.

(A)

inch

A

B

C

RL 70

7

9/32

“

10

27/32

“ - 12

13/16

“

1/2

W

RL 100

7

9/32

“

10

27/32

“ - 12

13/16

“

1/2

W

RL 130

7

9/32

“

10

27/32

“ - 12

13/16

“

1/2

W

Nozzle

size

GPH

MBtu/hr

174 PSI

145 PSI

174 PSI

203 PSI

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.3

8.5

9.0

9.5

10.0

10.5

11.0

12.0

12.3

13.0

13.8

14.0

15.0

15.3

16.0

17.0

17.5

18.0

19.0

19.5

20.0

21.5

22.0

6.15

6.76

7.40

8.00

8.61

9.22

9.86

10.21

10.47

11.08

11.69

12.30

12.94

13.54

14.76

15.15

16.01

17.00

17.23

18.48

18.83

19.69

20.94

21.55

22.16

23.38

24.01

24.62

26.48

27.09

6.79

7.46

8.17

8.84

9.51

10.18

10.85

11.27

11.56

12.23

12.90

13.58

14.28

14.95

16.30

16.71

17.64

18.73

19.02

20.37

20.78

21.74

23.09

23.76

24.46

25.81

26.48

27.15

29.20

29.86

7.40

8.13

8.87

9.60

10.34

11.08

11.81

12.26

12.55

13.29

14.06

14.76

15.50

16.23

17.71

18.16

19.18

20.27

20.65

22.16

22.57

23.63

25.10

25.84

26.58

28.05

28.79

29.52

31.73

32.47

951

1044

1144

1238

1331

1425

1519

1578

1618

1712

1806

1901

1999

2093

2282

2339

2470

2622

2663

2852

2909

3044

3233

3326

3424

3613

3707

3801

4088

4180

(B)

(C)

D455

D2326

D690

(D)