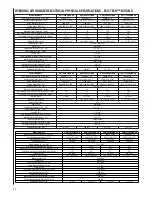

24

!"#

$"!%&

!"%

$"!'&

!"(

$"!)&

!"*

$"#!&

!"'

$"#%&

!"+

$"#'&

!")

$"#)&

!",

$"#-&

!"-

$"%%

./0

+,+

$(%*&

+(*

$%--&

',%

$%)'&

'(!

$%'!&

12345/0

)%(

$(*#&

+,,

$(%'&

+#)

$%-#&

'+)

$%+,&

'#%

$%*%&

*'-

$%#)&

123

)*,

$('(&

+-)

$(%-&

+*,

$(!+&

'-)

$%,%&

'*,

$%'-&

*-#

$%(%&

**'

$%#!&

12346786

-%%

$*('&

,,'

$*#,&

,*-

$*!#&

,##

$(,(&

))'

$(++&

)((

$(*+&

+-'

$(%,&

+**

$(!*&

+*'

$(!*&

9786

-*!

$***&

-#)

$*((&

,)'

$*#(&

,(,

$(-'&

)--

$())&

)+!

$('-&

)#+

$((,&

+)(

$(#,&

+%,

$%-+&

./0

+*+

$(!'&

',%

$%)'&

'#)

$%**&

*(+

$%!+&

12345/0

-,*

$*+*&

-()

$**%&

,-*

$*%%&

,*+

$(--&

)-,

$())&

)')

$(')&

)#!

$(('&

123

#!() $*,-&

--'

$*)!&

-'(

$*'!&

-#!

$*%-&

,+,

$*#!&

,%#

$(,)&

),#

$(+-&

)()

$(*,&

12346786

##+# $'*,& #!%! $*,#& #!), $'!-& #!*! $*-#&

---

$*)#&

-+(

$*'*&

-%!

$*(*&

,)(

$*#%&

)'(

$(''&

9786

#(-) $+'-& #('* $+(-& #(%# $+%(& #%)- $+!*& #%(, $',*& ##-( $'+(& ##') $'*+& #!+, $'!*&

-'+

$*'#&

./0

,#'

$(,'&

)+'

$(+#&

)#'

$(()&

++'

$(#*&

+#*

$%-!&

'',

$%+(&

'#*

$%*(&

12345/0

#%,* $+!+& #%(( $',%& ##), $''+& ##%- $'((& #!)! $'!'&

---

$*)#&

-%)

$*()&

,)+

$*#(&

,%(

$(,,&

123

#*#- $+)!& #()( $+*,& #(%( $+%*& #%,% $+!'& #%%, $',!& ##,! $'')& ##%- $'((& #!'* $*-)&

-,#

$*+(&

12346786

#*,' $)!#& #*'% $+,'& #*#, $++-& #(,+ $+'*& #(*+ $+('& #(#( $+%!& #%)% $+!!& #%%% $'))& ##-' $'+*&

9786

#)*' $,%*& #)%% $,#(& #+-% $)--& #++* $),'& #+(! $)+-& #'-- $)''& #'++ $)(-& #'!* $)#!& #('+ $+*!&

./0

#!** $*-(&

-'(

$*'!&

,+)

$*!-&

)+)

$(+%&

++)

$(#'&

')-

$%)(&

'!#

$%(+&

12345/0

#!#! $*))&

-)!

$*',&

-(+

$**%&

-!%

$*%+&

,+)

$*!-&

,(%

$(-(&

)-,

$())&

)++

$(+%&

)%'

$(*%&

123

#%*) $',-& ##,( $'',& ##%# $'%-& #!+* $'!%&

---

$*)#&

-((

$**!&

,+*

$*!,&

)-)

$()+&

)('

$(*)&

12346786

#,(* $,++& #)+, $,(*& #+-) $,!#& #+(- $))*& #',' $)*,& #'(- $)%+& #*), $+-,& #*%) $+)(& #()! $+*)&

9786

%!!, $-*,& #-'+ $-%(& #-!' $,--& #,** $,)!& #,!% $,'!& #)'! $,%+& #+-, $,!#& #+'' $),#& #+!* $)')&

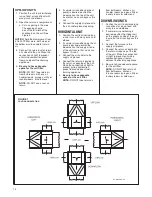

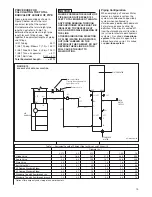

:5/02;<=2;>/;?@A2<B2@CD;23<07E6/DE<>75E2;<7?<=5@A2

4

4

4

FG#H#!I+!%*JII

##<K<##<<<<<<<<<<<<

$%)-<K<%)-&

(L*<<$''-&

4

4

FG#H!,I*,%#JII

#!<K<#!<<<<<<<<<<<<<

$%'*<K<%'*&

(L*<<$''-&

4

4

FG#H!+I(+#)JII

#!<K<,<<<<<<<<<<

$%'*<K<%!(&

#L%<<$()(&

4

4

4

4

4

4

4

4

4

4

4

4

4

FG#H!*I%*#*JII

#!<K<+<<<<<<<<<<<<

$%'*<K<#'%&

#L(<$%*,&

4

4

!"#$%&'()*'$)!*&#+,$)*'$)-+%.)/,$-%$0*&(,)1),(!%)2,(!)0%#,+3

1/325

:5/02;<M7N2<7?<<

$BB&

1/E/;<9O<<

$G@EE&

:5/02;<M=223

(-0)4+567)*89)#:;8<:9=)),>?:9@A;)3?A?8B)/9:66C9:)'@BD:6).A?:9)(E;CF@)4G/A7

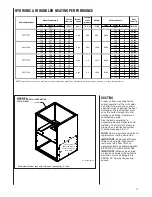

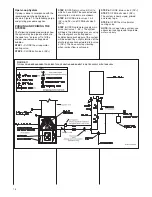

DIRECT DRIVE

INSTRUCTIONS FOR

CHANGING BLOWER SPEED

DISCONNECT THE ELECTRICAL

SUPPLY TO THE AIR HANDLER

BEFORE ATTEMPTING TO

CHANGE THE BLOWER SPEED.

FAILURE TO DO SO CAN CAUSE

ELECTRICAL SHOCk RESULTING

IN PERSONAL INJURY OR DEATH.

The blower motor must be wired for

blower speeds required for normal

operation.

If additional blower speed taps are

available (leads connected to “M1” and

“M2” on the electronic control), speeds

may be changed if necessary to fit

requirements of the particular

installation. Reconnect the unused

motor leads to “M1” or “M2.” Check

motor lead color for speed designation.

!

WARNING

TABLE 2

Heating speeds should not be

reduced where it could cause the air

handler air temperature rise to

exceed the maximum outlet air

temperature specified for the unit.

IMPORTANT:

Always check air

temperature rise after changing the

heating speed for any reason.

HYDRONIC AIR HANDLER AIR FLOW PERFORMANCE -PSC MODELS

Model

Blower Size

in [mm]

Motor HP

[Watt]

Blower Speed

RW1P04A2414NAA

10 X 6

[254 X 152]

1/5 [93]

RW1P06A3617NAA

10 X 8

[254 X 203]

1/2 [373]

RW1P08A4821NAA

10 X 10

[254 X 254]

1/2 [373]

RW1P10A4821NAA

11 X 11

[279 X 279]

3/4 [559]

0.1 [.02]

0.2 [.05]

0.3 [.07]

0.4 [.10] 0.5 [.12] 0.6

[.15] 0.7 [.17] 0.8 [.17]

0.9 [.22]

CFM [L/s] Air Delivery External Static Pressure Inches Water Column [kPa]

Low

642 [339] 612 [322] 591 [311] 524 [273]

—

—

—

—

—

Med-low

711 [377] 684 [362 655 [346] 624 [329] 578 [303] 526 [274]

—

—

—

Med-high

890 [477] 853 [456] 821 [438] 786 [419] 744 [396] 694 [368] 633 [334] 549 [287]

—

High

950 [510] 917 [492] 880 [471] 843 [451] 803 [428] 752 [400] 689 [365] 690 [366] 604 [318]

Low

900 [482] 882 [472] 865 [463] 843 [451] 806 [430] 759 [404] 687 [364] 617 [325]

—

Med-low

1135 [613] 1101 [594] 1073 [578] 1050 [566] 1012 [544] 960 [516] 889 [476] 801 [427] 700 [371]

Med-high

1260 [682] 1231 [666] 1199 [648] 1154 [623] 1113 [601] 1060 [571] 978 [526] 895 [479] 767 [408]

High

1397 [758] 1363 [739] 1314 [712] 1268 [687] 1209 [654] 1148 [620] 1077 [581] 980 [527] 829 [443]

Low

947 [508] 943 [506] 940 [504] 926 [497] 897 [481] 857 [458] 784 [418] 711 [377]

—

Med-low

1200 [649] 1193 [645] 1183 [639] 1163 [628] 1137 [614] 1084 [584] 1025 [552] 917 [492] 769 [409]

Med-high

1493 [812] 1481 [805] 1452 [789] 1411 [766] 1365 [741] 1220 [660] 1124 [607] 957 [514]

—

High

1865 [1018] 1810 [988] 1737 [947] 1671 [911] 1608 [876] 1533 [834] 1457 [792] 1292 [700] 1135 [613]

Low

904 [484] 875 [468] 845 [452] 798 [426] 735 [391] 688 [364] 643 [339] 593 [312] 539 [282]

Med-low

1189 [643] 1165 [629] 1114 [601] 1092 [589] 1057 [569] 1005 [541] 947 [508] 879 [471] 821 [438]

Med-high

1326 [719] 1304 [707] 1286 [697] 1266 [686] 1244 [673] 1217 [658] 1189 [643] 1140 [616] 1060 [571]

High

1970 [1077] 1951 [1066] 1937 [1058] 1926 [1052] 1895 [1035] 1865 [1018] 1759 [959] 1673 [912] 1624 [884]

Blower performance measured without filter in place.

!"#

$"!%&

!"%

$"!'&

!"(

$"!)&

!"*

$"#!&

!"'

$"#%&

!"+

$"#'&

!")

$"#)&

!",

$"#)&

!"-

$"%%&

./0

%'(

##-

%*!

##(

%%(

#!'

#--

-*

#,%

,+

#)(

,%

#+#

)+

123

123

123

123

4567./0

'#,

%**

'%!

%*'

'##

%*#

'!-

%*!

'!!

%(+

*-,

%('

*-+

%(*

*,!

%%)

*)(

%%(

456789:;

+'%

(!,

+'(

(!,

+',

(##

+',

(##

+'#

(!)

+*,

(!+

+**

(!*

+(*

%--

+%*

%-*

89:;

-!'

*%)

-#+

*(%

-##

*(!

-%%

*('

-#(

*(#

-#+

*(%

-##

*(!

-!*

*%)

,-%

*%#

./0

*!!

#,-

*##

#-*

*(%

%!*

*%%

#--

*##

#-*

*#%

#-*

(,#

#,!

(,!

#)-

()'

#))

4567./0

)*'

('%

))!

(+(

))+

(++

))!

(+(

),'

()!

),*

()!

),!

(+,

))'

(++

))!

(+(

456789:;

--!

*+)

#!#(

*),

#!*'

*-(

#!*!

*-#

#!',

*--

#!'%

*-+

#!'(

*-)

#!'!

*-+

#!*'

*-(

89:;

#%'%

'-#

#%+*

'-)

#%)-

+!*

#%),

+!(

#%,+

+!)

#%,'

+!+

#%,'

+!+

#%)'

+!%

#%)!

'--

./0

')+

%)%

''-

%+*

'(,

%'*

'#,

%**

*-,

%('

*)(

%%(

*''

%#'

*('

%!'

*#'

#-+

4567./0

,-,

*%*

-#%

*(!

-%-

*(,

-(%

**!

-!%

*%+

-!#

*%'

,,!

*#'

,+(

*!)

,*+

(--

456789:;

#(#,

+%%

#(*'

+('

#()(

+*,

#()+

+*-

#()'

+*-

#())

+'!

#(+,

+*+

#(')

+*!

#%-)

+#%

89:;

#+#'

)+%

#+#*

)+%

#+#,

)+*

#+!(

)')

#+!(

)')

#'-%

)'#

#',,

)*-

#')*

)*(

#'%'

)%!

./0

,##

(,(

)-+

()+

)+*

(+#

)!)

((*

+))

(%!

+''

(!-

+((

%--

+%!

%-(

+#!

%,,

4567./0

---

*)#

--+

*)!

--+

*)!

--#

*+,

-,%

*+(

-+(

*'*

-('

**#

-!'

*%)

,)%

*#%

456789:;

#'(*

)%*

#'%*

)#-

#'(-

)%+

#''+

)(*

#''!

)(%

#'*)

)(!

#'*(

)%,

#'((

)%(

#'(%

)%(

89:;

#)-'

,*)

#)-,

,*-

#,!!

,'!

#,!#

,'!

#,!*

,'#

#)-%

,*+

#),*

,*%

#))%

,(+

#)'(

,%)

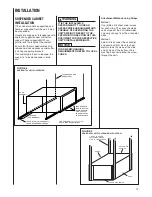

8<=>?1@AB3@>B831=.C>B3@>BD.?EBFC>D?>431ACB7CA4B4?=C.G

4/65H

IH/05JBG9K5B9LB$MM&

4/N/JB8FB$EONN&

IH/05JBGP556

AD4B$.2Q&B39JB=5H9R5JSBCTN5JLOHBGNON9UBFJ5QQVJ5B@LU;5QBEON5JBA/HVMLB$WFO&

>E4X!+3(+#)133

#!BYB,B$%'*BYB%!(&

#2%B$(!*&

>E4X!*3%*#*133

#!BYB+B$%'*BYB#'%&

#2(B$#,!&

(2*B$*+'&

#!Y#!B$%'*Y%'*&

>E4X!,3*,%#133

>E4X#!3*,%#133

##BYB##B$%)-BYB%)-&

(2*B$'%!&

Содержание RW1P

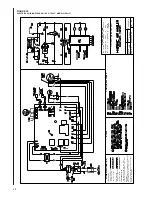

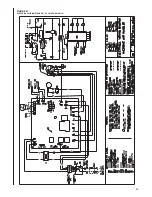

Страница 29: ...29 FIGURE 21 ELECTRICAL WIRING DIAGRAM PSC MOTORS RW1P...

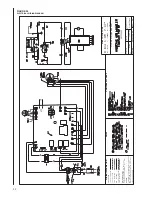

Страница 32: ...32 FIGURE 24 ELECTRICAL WIRING DIAGRAM...

Страница 33: ...33...

Страница 34: ...34...

Страница 35: ...35...

Страница 36: ...36 CM 0617...