20

CAUSE

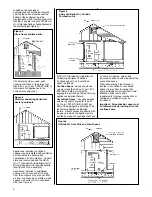

1. Roof peak or other surrounding

objects higher than chimney top.

2. Flue cap on chimney.

3. Coping smaller than chimney

interior.

4. Air leak from loose bricks or

mortar.

5. Inside dimensions of chimney are

too small.

6. Double chimney separation wall

leaks due to loose bricks or

mortar.

7. Joist protruding into chimney.

8. Brick, mortar or other obstruction

lodged in chimney.

9. Soot accumulation in offset.

10. Offset is too short.

11. More than one heating appliance

connected to same chimney flue.

12. Smoke pipe protrudes into chimney

or elbow too far.

13. Smoke pipe is loose fitting, too

long or has too many elbows.

14. Opening between chimney flues.

15. Loose fitting cleanout door.

16. New chimney.

17. Excessive draft..

CORRECTION

Extend chimney 24 inches above roof

and surrounding objects within 30 feet.

Remove.

Enlarge to match chimney interior.

Replace loose bricks and mortar.

If all other causes have been

eliminated a new chimney may have

to be built.

Replace loose bricks or mortar.

Remove.

Have chimney cleaned.

Clean out.

Straighten or lengthen offset.

Furnace ideally should have its own

flue. If this is not possible, smoke pipe

should be connected as shown in

Figure 23.

Make flush with inside of chimney.

Cement joints, shorten and eliminate

elbows.

Seal openings permanently.

Seal openings, close door tightly.

Allow 2 to 4 weeks to dry.

Open barometric damper.

CORRECTION OF POOR CHIMNEY DRAFT CONDITIONS

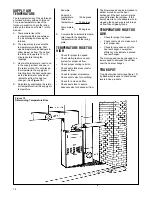

FIGURE 24. CHIMNEY PROBLEMS

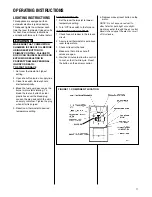

FIGURE 25.

Pipe pushed too far

inside elbow, as shown, interferes

with draft.

FIGURE 26.

If chimney ends only a

short distance below point where

flue enters, make a “toothpick joint”

as shown. Remove soot from below

regularly.

FIGURE 27.

If it is necessary to

connect more than one heating

appliance to the same chimney,

connect furnace flue pipe as “B.”

Connect lower BTU appliance pipe

as “A.”

Содержание LX2000 Series

Страница 10: ...10 TYPICAL INSTALLATION DIAGRAMS FIGURE 9 TWO PIPE INSTALLATION FIGURE 10 ONE PIPE INSTALLATION...

Страница 27: ...27 PARALLEL WIRING UPFLOW OIL FURNACES SCHEMATIC...

Страница 28: ...28 HEATING AND COOLING CONTINUOUS LOW SPEED BLOWER SCHEMATICFIGURE 38...

Страница 29: ...29 FIGURE 38 FOR MODELS WITH UTEC 1012 925 INTEGRATED FURNACE CONTROL...

Страница 30: ...30...

Страница 31: ...31...

Страница 32: ...32 CM 898...