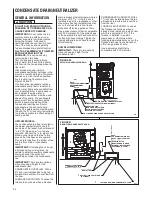

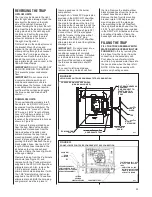

Refer to Figure 36 for Steps 6-11.

6. Locate the parts bag in the

burner compartment. Install two

plastic plugs

➅

in the side of the

jacket from bottom side up.

7. Attach the gasket

➇

onto the trap

assembly so that the gasket

holes on the gasket line up with

the holes on the trap assembly.

8. Fill the trap assembly

➆

with 1/2

cup of water.

9. Insert the trap assembly with

gasket up through the existing

hole in the jacket and secure

from inside the jacket. Use two

screws provided. Screw down

into the two “ears” molded into

either side of the trap. Snug the

trap assembly against the

furnace jacket compressing the

gasket slightly to eliminate any

air leaks. Do not overtighten!

10. Attach the black molded rubber

90° elbow

➂

to the straight spout

on the trap top using a white

nylon clamp

➂

. Attach the other

end of the rubber elbow to the

spout

➂

located on the exhaust

transition

➂

using a white nylon

clamp.

11. Attach the 90° end of the molded

hose

➂

to the collector box.

Clamp the hose tight with a white

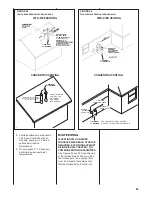

CONDENSATE DRAIN

FOR HORIZONTAL

INSTALLATION

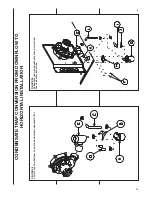

Refer to Figure 35 for Steps 1-5.

1. This unit is shipped factory ready

for downflow installation. The

condensate trap assembly and

drain hoses require conversion

for horizontal installation.

Remove the existing condensate

trap with the unit in the upright

position.

IMPORTANT:

This furnace may

only be installed so that when

facing the front of the furnace,

supply air is discharged on the

left hand side.

2. Remove the burner compartment

door from the unit.

3. Remove the two screws from the

right side of the furnace jacket

which support the trap mounting

bracket

➂

. Remove the two

plastic plugs on either side of the

trap outlet hole and discard.

4. Remove the black molded 90°

hose

➂

from the top of the

existing trap

➂

and from the

furnace collector box. Cut 1.0

inch from the long end of the

hose.

5. Remove the double-elbow black

molded hose

➂

from the exhaust

transition

➂

. Discard this hose

and the downflow trap. Retain

the clamps for future use.

Additional clamps are provided in

the parts bag if any clamps are

damaged during conversion

process.

NOTE:

The following steps should

take place with the furnace in the

horizontal position.

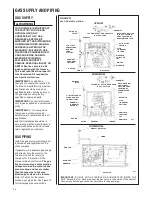

34

FIGURE 34

HORIZONTAL CONDENSATE DRAIN

I408

CONDENSATE TRAP

DRAIN LINE

NEUTRALIZER CARTRIDGE

(OPTIONAL)

TO FLOOR DRAIN OR CONDENSATE PUMP

NOTE:

SEE GENERAL NOTES FOR

HORIZONTAL MODELS

FOR PIPE HEIGHT.

OVERFLOW LINE

(REQUIRED ONLY WHEN

OPTIONAL NEUTRALIZER

CARTRIDGE IS USED.)

nylon clamp. Then attach the

long end of the molded hose to

the 45° elbow molded into the

top of the trap assembly. Clamp

the hose tight with white nylon

clamp.

IMPORTANT:

Tighten all clamp

connections with a pair of pliers

and check for leaks after

conversion is complete.

11.

IMPORTANT:

There are two

options when choosing a height

for the condensate riser:

CONDENSATE OVERFLOW:

With a 1

3

⁄

4

inch riser installed

above the tee, a blocked drain

will result in overflow from the

riser.

FURNACE SHUTDOWN: To

cause the furnace to shut down

when a blocked drain is present,

install a riser which is a minimum

of 5

1

⁄

2

”. If the furnace is installed

in an attic, crawlspace or other

area where freezing

temperatures may occur, the

furnace drain can freeze while

shut off for long periods of time.

Use a solvent cement that is

compatible with PVC material.

CONVERTING DOWNFLOW TO HORIZONTAL

C

A

D

B

E

F

G

H

L

I

J

K

E