38

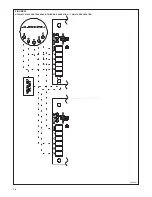

FIGURE 30

TROUBLESHOOTING FLOWCHART

GO TO

E

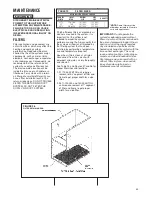

WARNING

INTEGRATED FURNACE CONTROL (IFC)

TROUBLESHOOTING GUIDE

HAZARDOUS VOLTAGE

LINE VOLTAGE

CONNECTIONS

DISCONNECT POWER BEFORE SERVICING.

SERVICE MUST BE BY A TRAINED, QUALIFIED

SERVICE TECHNICIAN.

NOTE: Most failures are not due to the IFC. Double check all other

possibilities, including the ground connection, before replacing the IFC.

NOTE: Always verify gas valve inlet and outlet gas

pressure.

KEY TO ABBREVIATIONS

IBM = Indoor Blower Motor

IDM = Induced Draft Motor

IFC = Integrated Furnace Control

PS = Pressure Switch(es)

SE = Spark Electrode

HSI = Hot-Surface Ignition

DSI = Direct-Spark Ignition

FLAME (AMBER) LED CODES

OFF = No Flame Present

RAPID BLINK = Unexpected Flame

SLOW BLINK = Marginal Flame Sense

STEADY ON = Normal Flame Sense

BLINK CODES (GREEN LED)

1 Blink - Soft lockout

Reset System power and

start over from beginning

2 Blinks - PS Circuit open

go to point “F.”

3 Blinks - Limit circuit open

go to point “D.”

4 Blinks - PS Circuit closed

Go to point “G.”

5 Blinks - Twin Fault (Optional)

*Go to point “H.”

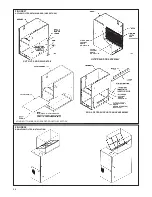

1) Set FAN switch to “AUTO”

2) Set thermostat to call for heat (set temp. differ-

ential to greater than 10°F

Does the IDM Energize?

IDM Runs for 30 sec. pre-purge?

Spark Ignitor Electrode (SE) Energizes

or HSI Ignitor Glowing?

Does Main Burner Light and stay lit?

Is the gas valve energized?

PS dropping out?

Check IFC*

Does IBM start on heat speed 20 seconds

after burners light?

Does main burner remain lit until

heat call ends?

Does thermostat maintain reasonable room

temperature near setpoint?

Set thermostat to off position (W to C = ØV)

Does gas valve shut off immediately?

Does IDM shut off after ten second post-purge?

Does IBM shut off after a max. of 3 min?

END

Heat-mode troubleshooting

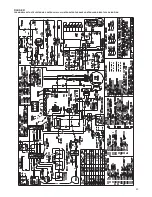

“POWER” LED ON?

24V on W to IFC?

Is “STATUS” LED blinking,

steady-on, or off?

Check IFC*.

Check IFC*.

Does IDM run

indefinately.

Does IDM Run for 60 sec. and then off for Five minutes

- Check thermostat in “heat” mode,

battery, wire, and connections.

SEE BLINK CODES

- Check 24V at IFC.

- Check Fuse.

- Check Door Switch and Line Power.

- Check Transformer.

- Check Breaker.

- Check PS contacts

- Check wires for short.

- Check IFC*.

- Check switches and hoses for

water or moisture

- For Twinned units, check that both IFCs are set for “TWIN” and wires

are connected between “TWIN” terminals.

- Check IFC*.

- For twinned units, ensure transformers are in phase.

(if out of phase, flame LED will be dim).

- For non-twinned units, ensure “TWIN” is in the single (OFF) position.

- For Twinned units – ensure both IFC‘s have same part number.

- Check PS, PS Hoses, and wires.

- Check for blocked vent, excessive vent length or elbows, or

blocked heat exchanger.

- Check IDM wired correctly.

- Ensure against excessive wind, which can open pressure switch.

- If downflow 90+, check aux. limit – shoud be closed

- Check for intermittent P.S. operation.

- Check switches and hoses for water or moisture.

- Check gas supply and manifold pressure.

- Ensure L1 and Neutral not swapped on IFC and junction box.

- Check SE alignment.

- Check orifice or other restrictions to gas flow.

- Check flame sense rod (clean with sandpaper).

- Check flame carry over.

- Check wires, continuity, and connection between IFC and gas valve.

- Ensure 24 V between appropriate pins on connector of IFC.

- Ensure manual switch on valve is in the “ON” position.

- 90+ check aux. limit open? Should be closed

- 90+ upflow models – check drain pressure switch between IFC and

gas valve – should be closed – replace drain pressure switch if drain

is not blocked or clear drain if blocked.

- Did a pressure switch open during ignition trial? If yes, go to F

- Did a limit open during ignition trial? If yes, go to D

- Check voltage between “HEAT” and “COMMON” on IFC.

- Check wires, connections, and continuity between

IFC and IBM.

- Check IBM capacitor.

- Check IBM.

CHECK:

- grounding on IFC and unit.

- check for proper polarity between L1 & neutral.

- flame sense rod (clean if necessary).

- wire continually between flame sense rod and appropriate pin of

connector on IFC

- flame carries across all burners, and all burners stay lit.

CHECK:

AIRFLOW - ensure no restrictions, such as dirty filter, dampers, closed registers, etc.

LIMITS - ensure good wire and connections between IFC and all limits. Make sure

limits are not open when circulating air temperature is within a specified range.

ROLLOUTS - ensure rollouts or overtemperature limits do not need to be reset. Make

sure no flame rollout in burner compartment due to blocked flu or heat exchanger.

OVERFIRE - ensure furnace is not overtemperature (temp rise is above stated range).

Check gas valve, proper orifice size, gas pressure, etc.

Is Limit circuit or IDM wire through aux. limit open or

opening and closing?

Note: IFC Status LED should be blinking a Fault Code 3.

Is the IFC sensing a good flame: NOTE:

Flame sense light should be steady-on

when burners are lit. If flame LED blinking,

or off, flame sense is low or absent.

Ensure thermostat is properly placed and not improperly affected by

registers, fans, sunlight, heat through walls, pipes, or wires in walls.

- Check heat anticipator setting. Furnace may need an isolation relay.

- Check installation instructions under section titled “Isolation Relay” for

details.

- Verify correct furnace sizing.

NOTE: If IFC goes into lockout (“STATUS LED will blink code “1”), shut

off main power to unit, wait 30 seconds and then reset power.

PROBLEM

STILL

PRESENT

“STATUS” LED

BLINKING

“FLAME” LED BLINKING

OR STEADY ON

If “E” did not

resolve issue

Double check - Is W off at IFC?

(W to C = ØV?)

Voltage present at gas valve?

- Check gas valve.

SEE BLINK CODES

- Check IFC*.

Check IFC*.

*Most failures are not due to the IFC. Double

check all other possibilities, including the

ground connection or wire connections, before

replacing the IFC.

Ensure TSTAT is not in “FAN” position.

Is “STATUS” LED blinking?

Is “FLAME” LED blinking or steady-on?

**System will attempt to light 4 times. Voltage

is present at gas valve for only 7 seconds dur-

ing each trial for ignition. The entire system will

go into a 1 hour lockout after 4 attempts. The

main blower and IDM will run 180 seconds

between 2nd and 3rd ignition attempts.

- Check line voltage at IDM.

- Check wires and connections between IDM and IFC.

- Ensure line voltage on IDM pins of IFC connector.

- Check IDM capacitor (90+ only).

CHECK BLINK CODES

- Check for open limit or limit circuit.

- Check for intermittent PS operation.

- Check for vent restrictions.

- Ensure vent lengths not excessive or

too small diameter.

- Check for blocked heat exchanger.

FOR SPARK IGNITION

- Check SE wire & connections.

- Clean SE with sandpaper. Replace SE if necessary.

- If problem persists, check IFC*.

- Check SE gas and proper SE ground.

- Check SE wire for spark arcing to metal before electrode.

FOR HOT SURFACE IGNITION

- Check ignitor connected.

- Check ignitor wires.

- Check ignitor resistance. If open circuit, low or high resistance, replace.

- Check ignitor for fractures or cracking

- Check ignitor placement.

- If problem persists, check IFC*.

START

REPEAT THIS PROCEDURE UNTIL TROUBLE-FREE OPERATION IS OBTAINED.

NO

NO

NO

If “

I

” did not

resolve issue.

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

BLINKING

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

STEADY-ON

I

D

F

H

E

G

YES

NO

YES

PREPURGE

IGNITION TRIAL

IBM “ON” DELAY

STEADY HEAT

END HEAT CALL

POST-PURGE

IBM “OFF” DELAY

STEADY OFF

NO

OFF

**

92-101654-01-00

GO TO

F

GO TO

I

PREPURGE