Air Flow Balancing (

cont’d

)

DUCT DIAM

.

5"

6"

CROSS SECTION AREA

0.136 sq. ft.

0.196 sq. ft.

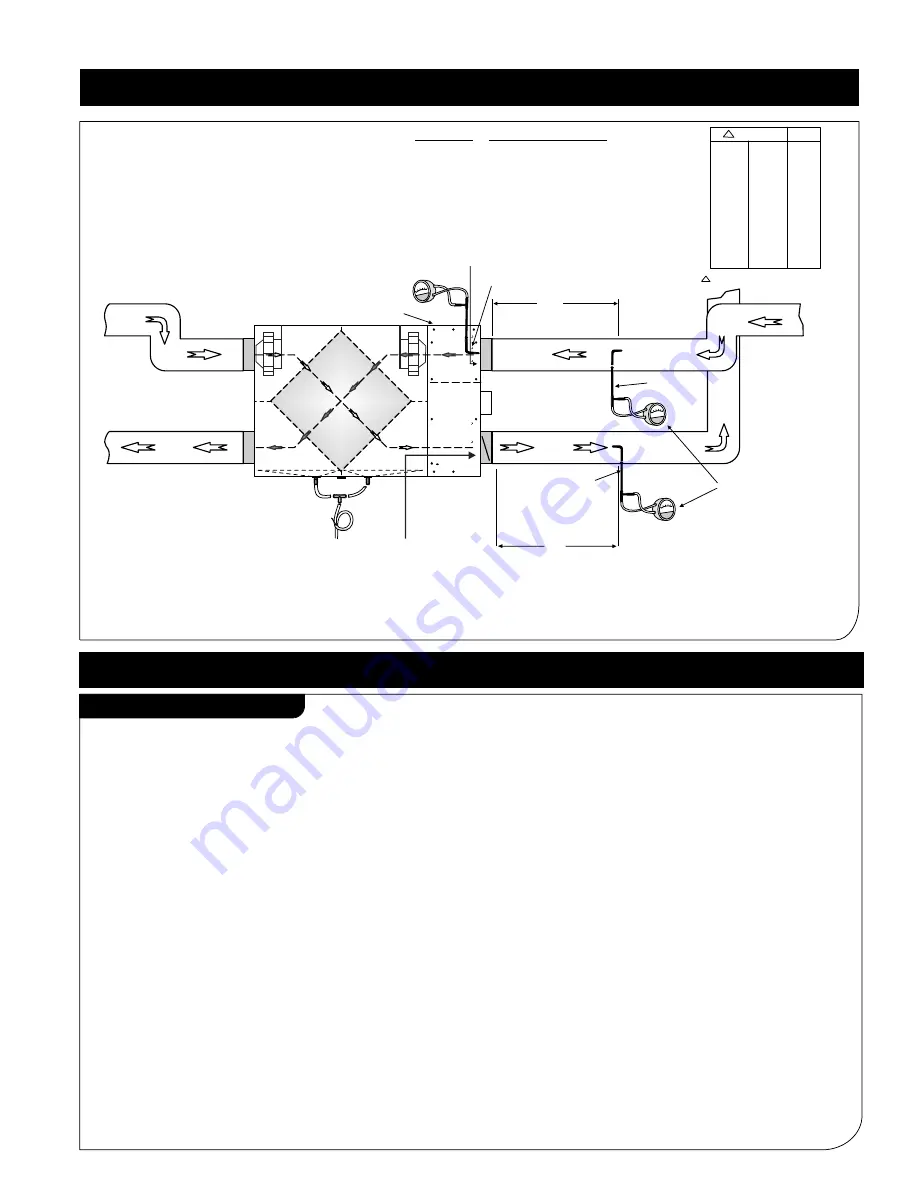

The accuracy of the flow reading will be affected by how close to any elbows or bends the readings are taken.

Accuracy can be increased by taking an average of multiple readings as outlined in the literature with the Pitot tube.

MAGNEHELIC

0

.1

.2

.3

.4

.5

MAGNEHELIC

0

.1

.2

.3

.4

.5

Magnehelic

gauge

Pitot

tube

Pitot tube

Min 3 ft straight duct

(option #1)

Min 3 ft straight duct

(option #2)

Note:

To take more accurate readings, use option #1(if possible).

Note:(Option #2)

*

For balancing, extension box cover plate is

provided with 3 holes on supply side and 3

holes on exhaust side.

*Do not use pitot tube to open holes in the

insulation as it may block/damage the pitot tube.

*Take 3 readings on each hole and average

all 9 readings for supply and same for exhaust.

*After finish balancing, plug all six holes with

plastic plugs provided with the unit.

Extension box cover plate

CFM = Opening / Cross-sectional Area(sq.ft.) x velocity(FPM)

Opening area: 0.2196sq.ft.

MAGNEHELIC

0

.1

.2

.3

.4 .5

Opening area: 0.136 sq.ft.

1. Turn the unit off and disconnect the power supply.

2. Unlatch the door and lift the door panel towards you, hold it firmly and slide it to the left.

3. Clean the inside of the

door

and

drain pan

with a damp cloth to remove dirt and debris

that may be present.

4. Clean the

filters:

(twice a year)

-

Remove the filters.

- Vacuum to remove most of the dust.

- Wash with a mixture of warm water and mild soap. Rinse thoroughly and shake filters

to remove water and let dry.

7. Check the exterior fresh air supply hood:

- Make sure there are no leaves, twigs, grass, ice or snow that could be drawn into the vent.

Partial blocking of this air vent could cause the unit to malfunction.

8. Reassemble the components, Filters and Door (The door is secured when you hear a click.)

9. Reconnect the power and turn on the unit.

5. Oil/grease defrost damper levers and hinges.

Regular Maintenance

15

Maintenance

Ø5 Ø6

0.010 0.004 50

0.012 0.006 60

0.016 0.008 70

0.022 0.010 80

0.027 0.013 90

0.034 0.016 100

0.041 0.020 110

0.048 0.023 120

0.057 0.027 130

P"

CFM

P = Velocity Pressure in inch

"

6. Check air flow sensors twice a year for lint/dust accumulation. If necessary, clean the sensors

.

with a lintfree cloth. Take extra care while handling. make sure supply sensor goes back to

supply diffuser and exhaust sensor goes back to exhaust diffuser on same original position.