Model S-1212 Operating Instructions

P/N 889-1910-00

4

Loop Fail

The number of loop failures logged in the loop fail register is displayed. Any time the detector enters the Fail Safe Mode due to a

recognized loop failure, the loop fail register is incremented by one count. When viewing the loop fail register, pressing either the

(UP) or

(DOWN) pushbutton will clear the register. The number of loop fail counts is also reset to zero by any power down or

when the detector channel is reset. The loop fail register is not reset when the detector channel’s sensitivity level or frequency is

changed.

After the detector is initialized and operating in a normal manner, the loop is continuously monitored for faulty conditions (e.g. broken

wires, poor splices, bad solder connections, etc.). If the measured loop inductance value rapidly changes by more than ±25%, the loop

is considered to have failed. The detector then enters the Fail Safe Mode, which generates a constant Call output. When the detector

is in Fail Safe Mode, the

LOOP FAIL

symbol located at the bottom of the LCD will be illuminated and the LCD will display

L lo

for

low loop inductance and shorted loop situations or

L hi

for high loop inductance and open loop situations. In addition, the Detect

/Fail LED will begin to emit a flashing pattern (three flashes per second). If the loop self-heals, the detector and LCD will resume

normal operation. The LED will continue to flash as a means of indicating a prior loop fail condition and will continue to do so until

the loop fail register is cleared.

Firmware Version

The version and revision level of the firmware programmed into the detector are displayed. This is a view only parameter. The

display alternates between the model letter and firmware version (e.g.

S35

) and the firmware revision level (e.g.

.00

).

III

Reset Procedures

•

Pressing and holding the

CHAN

pushbutton continuously for three (3) seconds will reset the displayed detector channel

maintaining all previous settings.

•

Changing the frequency or sensitivity setting will enter the new setting and reset the displayed detector channel. Changing any

of the other parameters will take effect immediately or on the next detection, but will not reset the displayed detector channel.

Simply entering the program mode without changing any parameter will not reset the displayed detector channel.

•

Pressing and holding all four front panel pushbuttons simultaneously and continuously for five (5) seconds resets the detector

and also restores all factory default settings.

•

The detector can also be reset by connecting a logic ground signal to Pin C of the edge card connector or by the reapplication

of power after a power loss.

•

The Loop Fail History is cleared by all reset procedures described above except changing frequency or sensitivity. Pressing

either the

(UP) or

(DOWN) pushbutton while viewing the Loop Fail History will also clear the Loop Fail History.

IV

Sensitivity Setting

Sensitivity is controlled by selecting a Sensitivity Level for the detector channel. The sensitivity settings of 1 through 9 represent

detection thresholds from the least sensitive to the most sensitive. Setting the proper Sensitivity Level for the loop circuit provides

stability to the system and improves count accuracy. If set too high, the detector may detect adjacent traffic. If set too low, the

detector may not detect small vehicles or high bed vehicles.

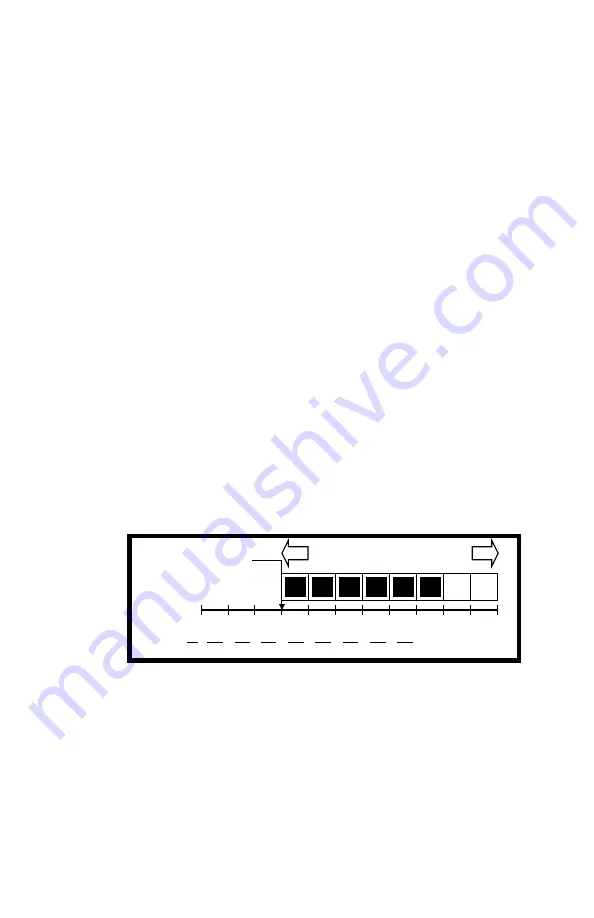

The LCD includes an eight (8) segment bargraph that is a representation of the relative change of inductance as seen by the detector.

This automatically takes into account loop size, loop inductance, number of loops, number of turns, loop geometry, lead-in length, etc.

The bargraph is a sliding scale that is related to the programmed Sensitivity Level. The first (left-most) bargraph segment represents

the minimum inductance change necessary for the detector to output a Call at the currently selected Sensitivity Level. Larger

inductance changes are indicated by more segments. Each additional segment indicates that the next Sensitivity Level has also been

met or exceeded. When used in this manner, the bargraph can be used to determine if the sensitivity is set too high or too low,

facilitating the optimal setting of the Sensitivity Level.

The diagram below shows the bargraph with the detector channel set to Sensitivity Level 6 (0.02% -

ΔL/L). The bargraph indicates

that the vehicle in the loop zone has exceeded the minimum Sensitivity Level by an additional five Sensitivity Levels or 0.64% -

ΔL/L.

The typical vehicle to be detected should cause five or six segments of the bargraph to become filled.

If the typical vehicle to be detected is not creating a five to six segment display on the bargraph, count how many segments are being

displayed and subtract six. If the number is positive, lower the sensitivity that many levels. If the number is negative, raise the

sensitivity that many levels. Example: The detector channel sensitivity is currently programmed at three (3). The bargraph shows

four (4) segments during a typical vehicle detection. Take four (4) (the number of segments displayed) and subtract six (6) to get

minus two (-2). Since the answer is negative, raise the Sensitivity Level, currently at three (3), by two (2) to arrive at the desired

Sensitivity Level of five (5).

The bargraph can also be used to take advantage of a direct relationship between the percent change of inductance caused by a single

standard automobile and a small motorcycle in the same loop / lead-in configuration. Adjusting the Sensitivity Level until seven (7)

segments of the bargraph are shaded when a standard automobile is present in the loop detection zone ensures that the sensitivity has

been set high enough to detect a small motorcycle in the same loop detection zone. The best method to reduce adjacent loop detection

is to reduce the Sensitivity Level by the number of segments that are flickering, however this will also eliminate the ability to reliably

detect small motorcycles.

Bargraph will slide with the

programmed sensitivity level

Bargraph shown with

Sensitivity set to Level 6

(0.02 %)

(%)-

∆

L/L

0.0025 0.005 0.01 0.02 0.04 0.08 0.16 0.32 0.64 1.28 2.56 5.12

Sensitivity

9

8

7

6

5

4

3

2

1

Level

Highest

Lowest