VIONiC REXM20/REXT20 installation guide

6

REXM20/REXT20 installation

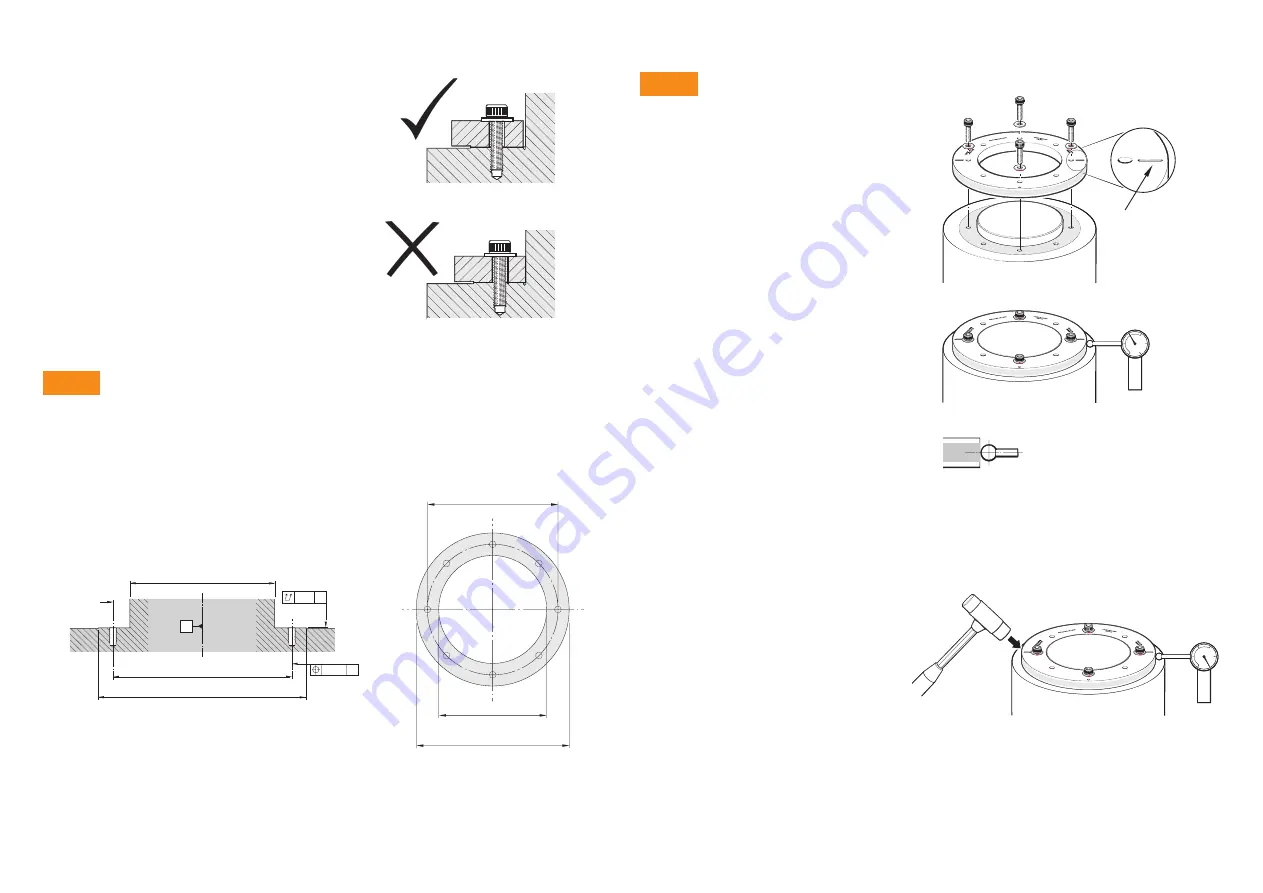

REXM20/REXT20 should be flange mounted onto a

flat surface; this eliminates all installation errors except

eccentricity, which can be compensated using twin

readheads.

X

Although taper mounting is best for thin

cross-section rings, it is not suitable for thick

cross-section REXM20/REXT20 rings.

X

The REXM20/REXT20

ring should be flange

mounted onto a flat surface to minimise

2-per-rev distortion.

X

Some eccentricity of the ring is acceptable

because it will be compensated by the use

of twin readheads.

X

To avoid distorting to the scale, the

REXM20/REXT20

should not be interference fitted.

There is a mounting face on the lower side of the

REXM20/REXT20 ring. A flat surface should be

prepared on the mounting shaft to match. The total axial

run-out of the mounting surface should be within 10 µm.

For dimensions D1, D2, D3, D4 and number of holes N, refer to

.

N × M5

× 10 deep

(< D1 ‑0.75)

D4

A

D1

D4

D2

D3

0.01

Ø 0.2

A

A

X

Remove the protective film from the surface

of the REXM20/REXT20 ring.

X

Clean the mounting face on the lower side

of the REXM20/REXT20. Clean the mating

surface on the mounting shaft.

X

Place the REXM20/REXT20 ring onto the

mounting shaft, then insert four M5 screws

with flat washers into the four screw holes by

the fiducial marks.

CAUTION:

Do not tighten the screws at this

point – simply engage the threads, ensuring

that the heads do not touch the ring.

NOTE:

For partial arc applications refer to

orientation for partial arc applications’, page 8

X

Set up a Dial Test Indicator (DTI) to measure

the run-out on the REXM20/REXT20 ring.

NOTE:

At this stage the ring is not firmly

fixed, so to avoid causing the ring to shift

position, rotate the ring slowly

and smoothly.

X

Where the DTI shows the lowest radius

reading, gently tap the opposite side of the

ring on the edge using a rubber mallet until

the DTI reading is approximately at the ‘mid

point’ of the run-out.

X

Now find the new lowest radius reading and

again tap the opposite side of the ring with a

rubber mallet until the DTI reading is at the

‘mid point’ of the run-out.

X

Continue this process until the run-out of the

ring is approximately 30 µm (0.0012 inches).

Use a DTI with low exertion force

to avoid scratching the scale

surface. A DTI with a ruby ball

stylus is recommended as a further

precaution against scratches.

Dimple or slot

indicates

fiducial mark

Step 1

Shaft preparation

Mounting

Step 2