13

14

A

B

C

D

E

G

H

2

1

F

-5-

long groove

long groove leftward

clearance

(a)

(d)

(b)

(c)

A

4.1 Coordination between needle, thread and sewing

material

Please use needle DP

17,Nm125-180.The coarseness

of needle should be in accordance with the nature of

material. If stitch on heavy duty material with a slim

needle, the needle will be easily bent, skip or thread

breakage occurs, on the contrary, stitch on tightly woven

material with a very coarse needle, the material will

be destroyed with over-big needle. So the needle and

thread should be properly selected.

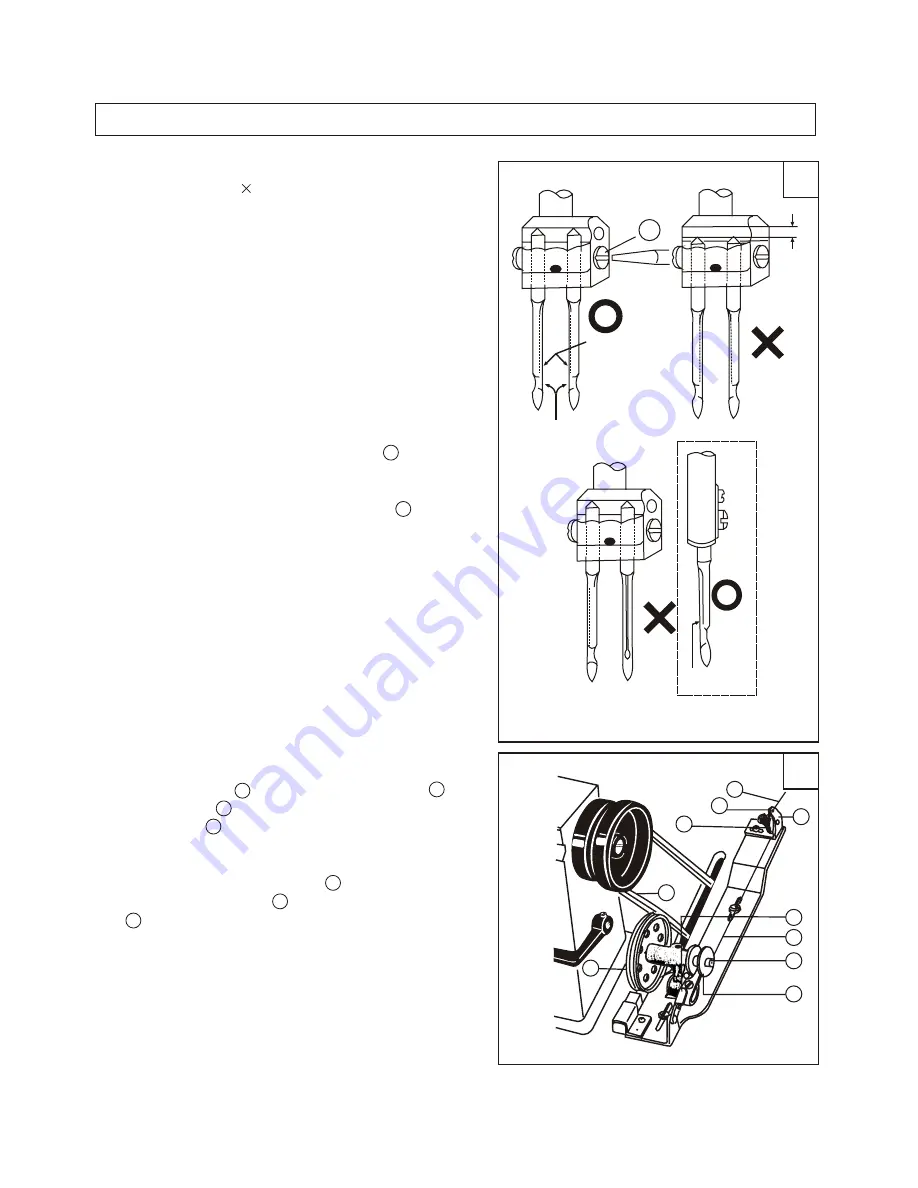

4.2 Needle installation(Fig.13)

Turn the balance wheel to lift needle bar to the

highest position, loosen Needle Set Screw A , fully

insert the needle shank upto the bottom of needle

socket, keeping the long grooves of the two needles

opposite with each other, then tighten Screw A , For

single needle, keep the long groove of needle facing

the left of the operator. See Fig (b).

Note: Fig.(c) : insufficient insertion.

Fig.(d) : wrong direction of needle long groove

in insertion.

4.3 Winding the Bobbin thread

4.3.1 Winding method(Fig.14)

1) Install bobbin A to bobbin winder spindle B .

2) Pass thread C from spool through the eye 1 on

tension bracket E . Pass ti between tension discs 2 ,

and then wind the end of the thread a few turns on

the bobbin.

3) Push stop latch thumb lever D down to lock the

bobbin, the winder pulley F is thereby pressed on

belt G .

4) Start the machine to wind thread.

Note when thread is wound without sewing opera-

tion, be sure to keep the presser foot lifted.

5) When the thread is fully wound, the bobbin winder

stop latch automatically release the bobbin winder,

thus stopping the winding motion.

( )

( ) ( )

( )

( )

( )

( )

( )

4. Operation

single needle

Содержание MSK-8400B

Страница 1: ...MSK 8400B MSK 8420B Industrial Sewing Machine Instruction Manual ...

Страница 14: ...Parts Manual ...

Страница 59: ...www reliablecorporation com ...