Regency CI1200 / CI1250 Wood Cast Insert

13

INSTALLATION

1)

Positive

Flue

Connection

with

Cleanout

2)

Direct

Flue

Connection

with

Cleanout

3a)

Full Flue Liner

(No

Cleanout

Required)

Note: A clean-out door is sometimes required,

by your inspector, to be installed when

either the Positive fl ue connection or

Direct fl ue connection method is used.

The use of one of the connection methods listed

on this page not only increases the safety of your

insert by directing the hot gases up the fl ue, but will

also help increase the unit's effi ciency and decrease

creosote deposits in the chimney.

When a connected fl ue or liner is in use, the insert

is able to “breathe” better by allowing a greater

draft to be created. The greater draft can decrease

problems such as, diffi cult start-ups, smoking out

the door, and dirty glass.

INSTALLATION INTO A

FACTORY BUILT

FIREPLACE

1)

When installed in a factory built fi replace, a full

stainless steel rigid or fl exible fl ue liner is manda-

tory, for both safety and performance purposes.

When a fl ue or liner is in use, the insert is able

to breathe better by allowing a greater draft to

be created. The greater draft can decrease

problems such as, diffi cult start-ups, smoking

out the door, and dirty glass.

2)

In order to position the fl ue liner, the existing

rain cap must be removed from your chimney

system. In most cases the fl ue damper should

also be removed to allow passage of the liner.

3)

In most cases opening the existing spark screens

fully should give enough room for the insert

When referencing installation or connection to

masonry fi replaces or chimneys, the masonry

construction must or shall be code complying.

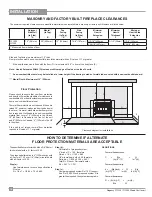

INSTALLATION INTO A

MASONRY FIREPLACE

The insert must be installed as per the requirements

of your local inspection authority. Three methods

of fl ue connection are acceptable in most areas,

these include:

1)

Positive

fl ue connection, where a large blocking

plate and a short connector pipe is used.

2)

Direct

fl ue connection, where a smaller blocking

plate and a connector pipe to the fi rst fl ue liner

tile is used.

3)

Full fl ue liner, where a stainless steel rigid or

fl exible liner pipe is routed from the insert outlet

collar to the top of the chimney.

Regency highly recommends the use of a full liner

as the safest installation and provides the most

optimum performance. Your retailer should be able

to help you decide which system would be the best

for your application.

In Canada this fi replace insert must be in-

stalled with a continuous chimney liner of 5.5"

or 6" diameter extending from the fi replace

insert to the top of the chimney. The chimney

liner must conform to the Class 3 require-

ments of CAN/ULC-S635 or CAN/ULC-S640,

Standard for Lining Systems for New Masonry

Chimneys.

4)

If

the

fl oor of your fi replace is below the level

of the fi replace opening, adjust the insert's

levelling bolts to accommodate the difference.

When additional shimming is required, use

non-combustible masonry or steel shims.

5)

Measure approximately the alignment of the

fl ue liner with the position of the smoke outlet

hole on the insert to check for possible offset. If

an offset is required, use the appropriate offset

adaptor in your installation.

6)

Once the above items have been checked, slide

your insert into position after fi rst positioning

and securing the fl ue liner to the offset adaptor.

Attach the rod to the adaptor and slide the

adaptor onto the unit as the unit is slid into

position. Ensure a positive connection.

Secure the adaptor to the unit by using 2 bolts,

fl at washers, lock washers and one screw in

the front.

Re-install raincap at completion of installation.