22 / 25

Section : 9 Troubleshooting

9.1

General Guidelines

This section informs the user how to quickly resolve an operational problem with the system.

During any troubleshooting phase, it will save time if the operator can firstly determine the

problem. Either it is related to the process controller, process sensor, or some external source.

Therefore, this section is organized from the approach of excluding any likely external sources,

isolating the transmitter and finally isolating the electrode. If these procedures still do not

resolve the operational problems, any results noted here will be very helpful when discussing

the problem with the factory technical support group.

•

Verify the proper power input is present (16 - 24V DC). Ensure the loads on the 4-20mA

outputs

don’t

exceed the limit (see section 1.3, 4.2).

•

Don’t put sensor cables or instrument 4

-20 mA output wires in the same conduit that

contains AC power wires. AC power wires should be run in a separate conduit to prevent

electrical noise from contacting with the instrumentation signals. Check for possible

ground loops. High frequency sources of electrical noise may cause abrupt behavior in

extreme conditions. If readings are very erratic after wiring has been checked, check for a

possible AC ground loop by temporarily moving the sensor to a sample of solution in a

beaker or other container.

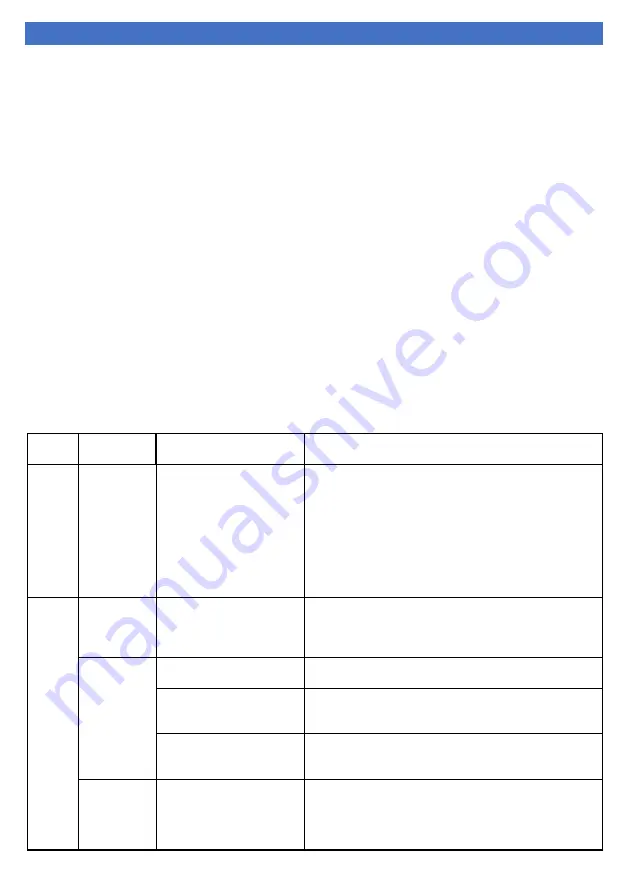

9.2

Troubleshooting Chart

ERROR

TYPE

ERROR

CODE

DESCRIPTION

TROUBLE SHOOTING

C

ali

bra

tio

n

Error 100

Cell constant out of range.

Calibration failed because

cell constant value is

either too high or too low.

Permissible range for cell

constant (

0.1 - 20

).

1- Clean probe by proper cleaning techniques.

(See section: 7.1 & 8.1.2)

2- Use valid buffer solutions.

(See section: 7.1 & 8.1.2)

3- Check probe for any physical damage.

(See section: 3 & 4.3)

4- Change the conductivity probe if it is damaged.

5- Enter proper conductivity value related to calibration

buffer solution.

G

ene

ra

l

White

Display

Low or high voltage /

display problem / contrast

not set / circuit board

issue

1- Check input voltage.

2- Set LCD contrast from display setting.

(See section: 8.1.1)

Blank

Display

Power not connected

Check input power connection.

(See section: 4.1, 4.2)

Power connections

polarity reversed

Check input power connections and reconnect in correct

polarity.

(See section: 4.1, 4.2)

Loose Power Connections

1- Check input power connection.

2- Tighten the power cables in terminal block.

(See section: 4.1, 4.2)

No

Conductivity

/ TDS Value

Display

Conductivity / TDS value is

too high or too low

1- Change the conductivity probe if it is damaged.

2- Clean probe by using proper cleaning techniques.

3- Perform calibration by using proper calibration

techniques.