Installation

2–26

F232048

Air Requirements

A clean, dry compressed air source is required

to operate the drain valve(s) and the supply

tank drain valves. The compressed air inlet for

the machine is on the rear of the machine.

Control Function Test

The machine should be cleaned after

the installation is complete. A function test

should then be executed on the unloaded

machine:

1.

Verify that the wire tie which keeps the

door lock open is removed.

2.

Check the power supply for such

characteristics as correct voltage, phase,

and cycles to be certain they are correct for

the machine.

3.

Open manual shut-off valves to

the machine.

4.

Turn on electric power.

5.

Check the door interlock before starting

operation:

a.

Open the loading door by pressing and

holding the door unlock button on the

front of the control panel and then

pressing the door handle button and

turning the handle clockwise.

b.

Attempt to start the machine

with the door open. The machine

should not start with the

door open.

c.

Close the door without locking it and

attempt to start the machine. The

machine should not start with the door

unlocked.

d.

Close and lock the door and start a

cycle. Attempt to open the door while

the cycle is in progress. The door

should not open.

e.

Open the sample port while the cylinder

is rotating. The cylinder should stop.

If the door lock and interlock are

not functioning properly, call a

service technician.

6.

Run a complete cycle, checking operation

of water inlet valves, drain, and extract

functions.

7.

Rotation must be forward in the extract

step. If rotation is not forward in the

extract step, disconnect power. A qualified

electrician must reverse any two leads

between the AC inverter drive and the

motor.

Air Supply Information

Air inlet connection size, in/mm

1/4 / DN6

Number of air inlets

1

Recommended air pressure,

psi/bar

90-95 /

6.0-6.3

Functioning limits, psi/bar

90-100 /

6.0-6.7

Содержание UY75

Страница 11: ...1 8 Notes F232048 Safety...

Страница 14: ...2 3 Installation F232048...

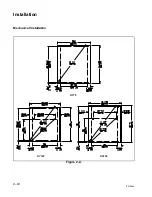

Страница 23: ...Installation 2 12 F232048 Mechanical Installation Figure 2 4 UY75 UY160 UY230...

Страница 47: ...3 10 NOTES F232048 Maintenance...

Страница 49: ...4 2 NOTES F232048 Removal From Service...