Appliance

The appliance must be installed on a solid level floor or

base of incombustible material which is capable of

supporting the total weight.

Location

The location chosen for the appliance must permit

installation and the provision of a satisfactory flue and an

adequate air supply. The location must also provide

adequate space for servicing and air circulation around

the appliance. See Section - Installation of Appliance -

General.

Meters

A gas meter is connected to the service pipe by the local

Gas Region or a local Gas Region Contractor. An existing

meter should be checked, preferably by the Gas Region,

to ensure that the meter is adequate to deal with the total

rate of gas supply required.

Installation Gas Pipes

Installation pipes should be fitted in accordance with local

gas fitting regulations. Pipework from the meter to the

appliance must be of adequate size. Do not use pipes of

a smaller size than the appliance gas connection. The

complete installation must be tested for soundness and

purged.

Detailed recommendations for fluing are given in Fluing

and Ventilation Standards.

The following notes are intended to give general

guidance:

The cross-section area of the flue serving the cooker must

not be less than the area of the flue outlet of the cooker,

and at least 3m high from the floor level.

If flue pipe is to be used it must not be less than 130mm

internal diameter.

Flue pipes and fittings should be constructed from one of

the following materials.

Material

Protective Finish

Mild Steel 1.6mm

None

Mild Steel 0.8mm over 100mm to 200mm dia. Z275 Zinc coated (AS 1397)

Mild Steel 0.8mm over 100mm to 200mm dia. Aluminised 122g/m

2

Mild Steel 0.8mm over 100mm to 200mm dia. Aluminised zinc coated

(AS 1397)

Stainless Steel 0.7mm over 100mm to 200mm dia.

430 & 300 Series grades

Fibre Cement light grade (asbestos free)

Autoclaved

Fibre Cement Heavy grade (asbestos free)

Autoclaved

Bricks (clay bldg) cement or lime mortar joints

Unprotected

Bricks

Parged with water and acid-

proof cement mix

Bricks

Inside face lined with acid-

resisting tiles embedded

in acid-resisting jointing

materials.

Precast concrete bricks or blocks

Unprotected

Flue bricks (see definition)

Nil or glazed internally

Firebricks, set in fireclay

None

Twin wall flue, AGA approved

The flue should terminate in accordance with the relevant

recommendations given in Fluing and Ventilation

Standards.

The flue pipe shall be terminated with an approved cowl

except where the authority specifically agrees otherwise.

The outlet of natural draught flue or chimney shall be so

located in relation to neighbouring constructions that wind

from any direction will not create downdraught in the flue.

FLUE SYSTEM

2

GAS SUPPLY

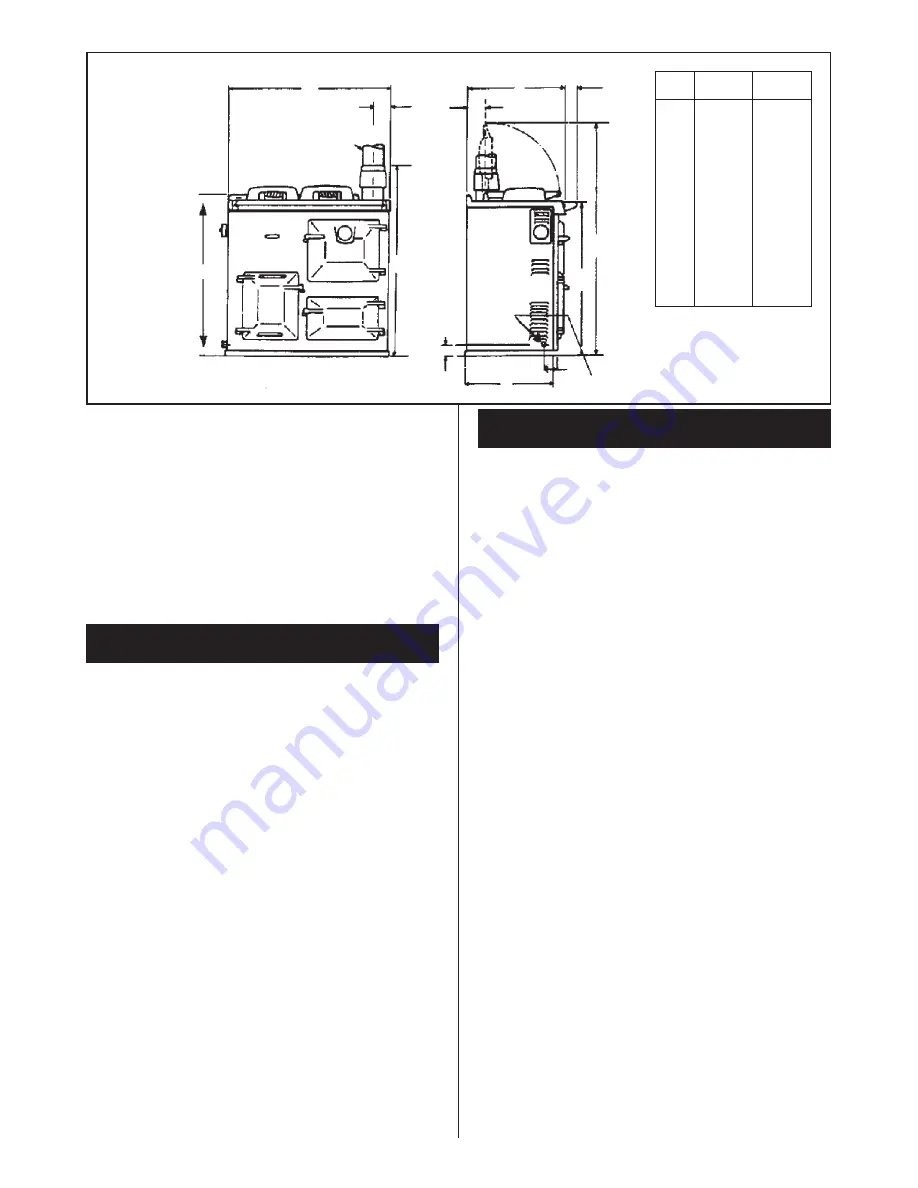

Fig. 1

A

B

M

J

F

G

D

C

L

E

K

H

4” (100mm DIA C.I. FLUE

GAS CONNECTION

mm

ins

A

840

33

B

848

33

5

/

16

C

820

32

1

/

4

D

1245

49

E

457

18

F

510

20

G

65

2

5

/

8

H

95

3

3

/

4

J

95

3

3

/

4

K

45

1

3

/

4

L

55

2

1

/

4

M

995

39

1

/

4

Содержание 200G/L Gas Fired Cooker

Страница 12: ...12 FAULT FINDING...

Страница 13: ...FAULT FINDING 13...

Страница 14: ...14...

Страница 15: ...15...