26

Manuale utente PALMARE IDRO TOUCH RADIO

Manuale utente PALMARE IDRO TOUCH RADIO

Pag.34

Pag.35

Vers. 01 del 07/04/15

Vers. 01 del 07/04/15

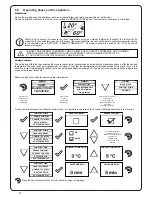

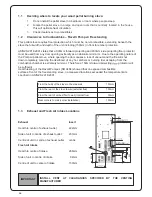

Layout 2 (storage puffer management)

In this type of circuit, the storage puffer is managed by the stove due to a contact or immersion probe (optional) connected to the

back of the stove.

Below is shown the new “Stand-by” mode.

The operation is the same as for the basic layout except for the fact that in this layout, the boiler exchanges heat directly in the puffer;

when the temperature set is reached, the stove switches to ECO STOP mode and then restarts if the temperature drops below a

restart value (set by the installer upon testing).

T°C Puffer

From STAND BY mode, press

the ARROW key to

set the desired puffer T°C

Boiler water T°C

CANNOT BE CHANGED

Press the key

“V” from STAND BY page

to display the actual states and

the room temperature

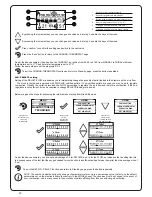

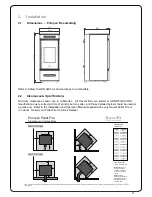

Layout 3 (DHW storage puffer management)

The following layout combines the functions of the previous layouts and is recommended to stoves provided with a puffer without

internal coil preset for domestic hot water.

In this type of circuit, the boiler is managed by the stove due to a contact or immersion probe (optional) to be connected to the back

of the stove. The same applies to the control of the puffer that is provided by the thermostove through a contact or immersion probe

(not supplied) connected directly to the back of the stove.

Below is shown the new “Stand-by” mode.

The operation is the same as for the basic layout except for the fact that in this layout, the boiler exchanges heat directly in the boiler

(priority); when the temperature set is reached, the 3-way valve changes its position and the boiler starts exchanging heat within the

puffer. When the set temperature is reached, the stove enters in ECO STOP mode; it restarts if the temperature drops below a restart

value (set by the installer upon testing).

The 3-way valve is directed again into the boiler when:

- there is a request from the Boiler;

- there is a requested from the flow switch (optional, if connected).

The stove restarts from Eco-stop or Stand by mode according to storage puffer requests or boiler requests.

By setting the SUMMER function, the 3-way valve remains fixed in a single position, enabling the release of heat output

by the stove exclusively inside the boiler. As soon as this condition is reached, the stove switches to ECO STOP mode.

T°C Boiler

From STAND BY mode, press

the ARROW key UP

to set the

DHW boiler T°C

that you desire.

T°C Puffer

From STAND BY mode, press

the ARROW key DOWN

to set

the desired puffer T°C

Press the key

“V” from STAND BY page

to display the actual states and

the room temperature

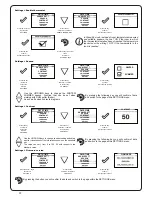

Stove phase general layout

FASE

DESCRIZIONE

FINAL CLEANING

The stove is in the switch off phase and the cooling phase has not been completed yet.

SWITCH ON

The heater pre-heating phase has started and the pellets start to fall into the grate.

WAITING FOR FLAME

The pellets ignite and take advantage of the heat in the intake air that passes through the

incandescent heater tube.

FLAME PHASE

The flame develops in the grate.

WORK AT MAX P

The stove has completed the switch on phase and runs at maximum set power

WORK AT MIN P

The stove works at the operating power set after ignition.

WORK AT DHW P

The stove works at an operating capacity dedicated to DHW

(flow switch request with DHW kit or DHW boiler)

MODULATE H2O

The desired boiler water set temperature has been reached.

ROOM TEMPERATURE

MODULATION

The room temperature set has been reached.

THE GRATE

Brazier cleaning phase is active (periodic function).

ECO STOP

With Climate Comfort active, the stove switches to automatic switch-off mode when

the room temperature set is reached (see the dedicated section).

START/RESTART WAIT

Switch-on is requested but with the stove in cooling phase; once this condition is met,

it restarts automatically.

SWITCH ON RESTART

The HOT restart phase is activated.

Functioning is similar to the SWITCH ON phase

HOT SMOKE

The maximum fume temperature threshold has been reached. To facilitate cooling, the stove

brings the capacity to a minimum with ventilation at power level 5, leading to a decrease in

fume temperature.

POWER

MOD

PUMP

3-WAY VALVE HEAT

3-WAY VALVE BOILER

HH T .

21°C

POWER MOD

PUMP

3-WAY VALVE PUFFER

PRESSURE 1.1 BAR

HH T .

21°C

Содержание Pompeii

Страница 14: ...Pull to clean exchanger tube bundle 12 5 8 How to Clean the Tubulators ...

Страница 32: ...30 25 Page 16 7 Maintenance Record SIGNATURE WORK CARRIED OUT DATE ...

Страница 44: ...42 1 2 x 4 2 12 How to mount the side panels ...

Страница 50: ...48 38 4 Maintenance Record DATE WORK CARRIED OUT SIGNATURE 40 ...

Страница 52: ......

Страница 53: ......