Use and maintenance manual Touch Radio Hydro

Pag.31

Rev.0 18/05/2021

EN

PROCEDURES FOR USE

⚠

If the chimney catches fire you must call the fire brigade immediately.

Checks prior to start-up

⚠

You have read and perfectly understood the contents of this instructions manual.

Before lighting the stove, you must ensure that:

•

the pellet tank is full;

•

the combustion chamber is clean;

•

the fire door and ash drawer seals are functioning properly;

•

the electrical plug is connected correctly;

•

all items that could burn (instructions, various adhesive labels) have been removed;

•

the brazier, if removable, is correctly positioned in its housing;

•

he hydraulic system valves are open properly.

📌

During the first hours of use the paints used for the stove finish may release an unpleasant odour. You might also smell the

typical odour of metal parts subject to high temperatures. Make sure sufficient air circulation is guaranteed in the room. These

unavoidable inconveniences will disappear after the first hours of operation. To reduce your discomfort to a minimum, keep

the stove on for a few hours on low power and in the beginning, do not overload it, avoiding intense heating-cooling cycles

📌

At the initial start-up, the paint finishes drying and hardens. Accordingly, to avoid ruining it, we advise you not to touch the

stove’s painted surfaces at this time.

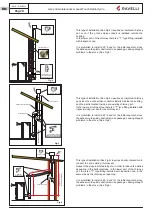

Feed screw loading

Before starting the stove for the first time, whenever the stove is in alarm “06 - Pellets finished”, and in any case whenever the hopper

has emptied completely, the initial feed screw loading is required.

This phase serves to fill the pellet loading system so that, at the time of ignition, the correct pellet loading takes place in the brazier.

In the event that the feed screw operations are not carried out, there may be stove ignition failures.

⚠

After loading the auger and before lighting the stove, always remember to empty the brazier and check that the brazier is

clean. Never empty the brazier inside the hopper.

⚠

After each maintenance operation, make sure that the brazier is positioned correctly in its seat.

⚠

In models with self-cleaning brazier it is not necessary to remove the pellets in the brazier: the pellets loaded are sufficient

for subsequent ignition.

By accessing the USER menu and then the LOADING AUGER menu, by pressing the confirmation key, the rotation of the auger is

activated to load the pellets into the brazier.

Switching the appliance on and off

From the “Home” screen, it is possible to switch the stove on and off by keeping the ON / OFF button

pressed on the device for a

few seconds. An acoustic signal will warn you that the appliance has switched on or off. In case it is not possible using your handheld

you can switch the appliance on / off using the appropriate button on the electronic board.

⚠

Do not switch off the heater by unplugging the plug from the wall socket.

📌

The appearance of the “SET RDS” message indicates that the initial parameter testing and calibration procedure was not

carried out correctly. This indication does not imply blocking the stove (see SIGNALLING POP UP section).

Failed ignition

If the system does not detect the ignition of the flame within the preset time, operation will be blocked with the “No ignition” alarm.

Before relighting the stove, check that there are pellets in the hopper, that the door and ash drawer compartment are closed, that

there are no obstructions to the combustion air inlet system and above all that, in models without self-cleaning brazier, the brazier is

empty, clean and correctly positioned. If the problem persists, it could be due to a technical problem (ignition plug, adjustments, etc

...), so please contact a Ravelli CAT.

⚠

The accumulation of unburned pellets in the brazier after a failed ignition must be removed before proceeding with a new

ignition.

LOADING AUGER

Содержание Hydro

Страница 1: ...USE AND MAINTENANCE MANUAL HYDRO Handheld Touch Radio Hydro...

Страница 2: ......

Страница 53: ......

Страница 54: ......

Страница 55: ......