Please note that the actual amount of grease needed for proper lubrication varies

according to:

hammer size

application: the amount of grease depends on the number of working cycles

within a given time. In practice this means that, in an application where the

working cycles are short but the quantity is high, a smaller dose can be used.

wear rate of the tool shank and bushing

condition of the tool seal

operators working techniques

grease quality

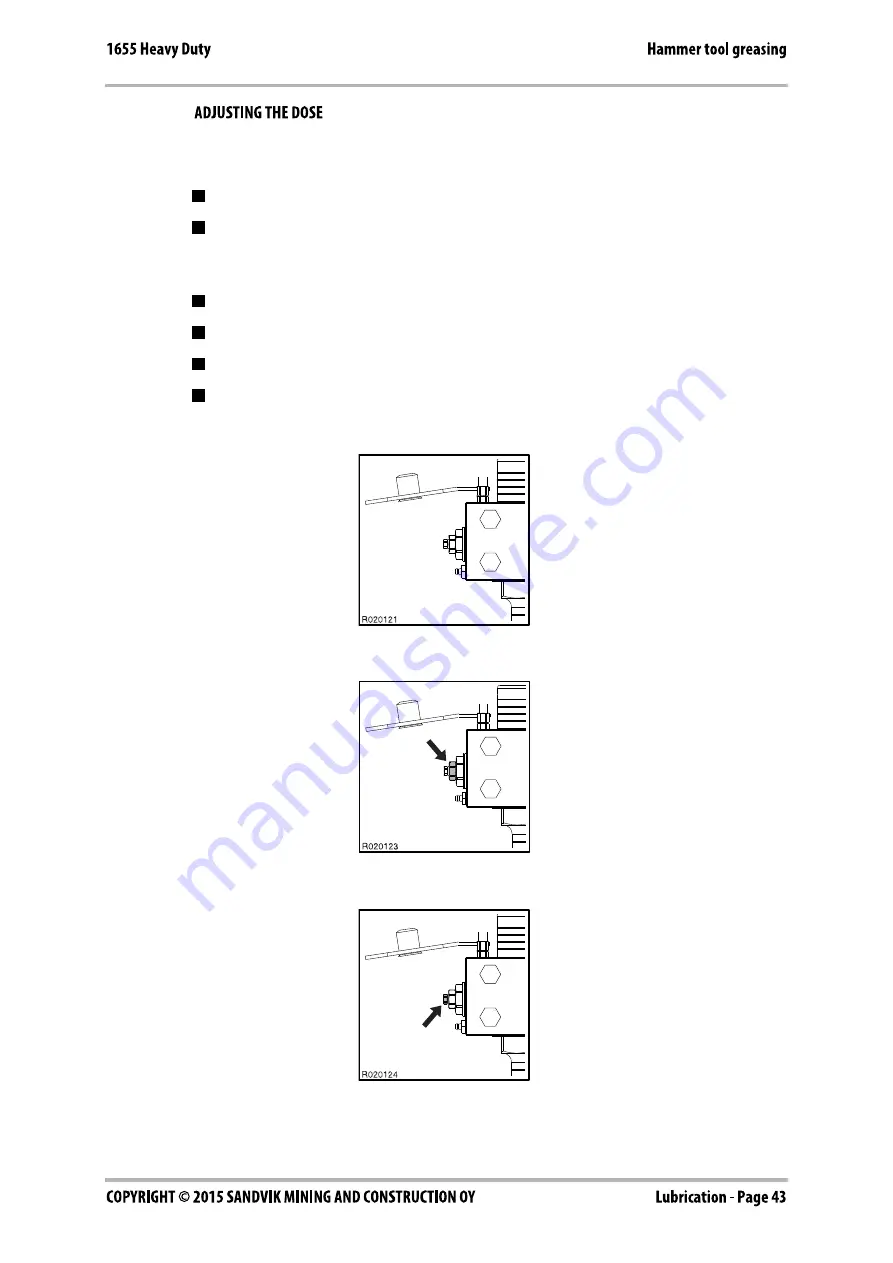

1. Turn the locking plate and plug aside.

2. Open the locking nut.

3. Turn the adjusting screw for grease dosage clockwise to close it completely.

4. Next open the adjusting screw for grease dosage by turning it counter-

clockwise as needed. See table below.