LTE Standard Module Series

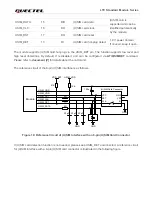

It is recommended to reserve test points for debugging and firmware upgrade in your designs. The

following figure shows a reference circuit of USB interface.

USB_DP

USB_DM

GND

USB_DP

USB_DM

GND

L1

Close to Module

R1

R2

Test Points

ESD Array

NM_0 R

NM_0 R

Minimize these stubs

Module

MCU

USB_VBUS

VDD

Figure 16:

Reference Circuit of USB Application

A common mode choke L1 is recommended to be added in series between the module and your MCU in

order to suppress EMI spurious transmission. Meanwhile, the 0

Ω

resistors (R1 and R2) should be added

in series between the module and the test points so as to facilitate debugging, and the resistors are not

mounted by default. In order to ensure the integrity of USB data line signal, L1, R1 and R2 components

must be placed close to the module, and also resistors R1 and R2 should be placed close to each other.

The extra stubs of trace must be as short as possible.

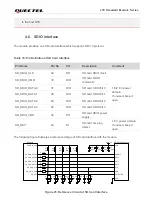

The following principles should be complied with when designing the USB interface, to meet USB

specifications.

⚫

It is important to route the USB signal traces as differential pairs with ground surrounded. The

impedance of USB differential trace is 90

Ω.

⚫

Do not route signal traces under crystals, oscillators, magnetic devices, PCIe and RF signal traces.

It is important to route the USB differential traces in inner-layer of the PCB, and surround the traces

with ground on that layer and ground planes above and below.

⚫

Junction capacitance of the ESD protection device might cause influences on USB data lines, so

please pay attention to the selection of the device. Typically, the stray capacitance should be less

than 2 pF for USB.

⚫

If possible, reserve a 0

Ω

resistor on USB_DP and USB_DM lines respectively.

For more details about the USB specifications, please visit http://www.usb.org/home.