20

04/21

7019-802H

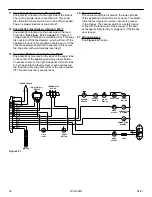

Figure 20.1

Cleaning

Rods

10 Heat Exchanger Tubes

6. Cleaning Heat Exchanger Chambers

• Frequency:

Weekly or every 1 ton of fuel

• By:

Homeowner

T

he amount of ash buildup in the firebox will be a good

guide to determine how often you should clean the heat

exchangers.

a. Allow the appliance to completely cool down before

pulling the cleaning rods.

Turn the thermostat

on and then immediately off to start the exhaust

blower on its cycle time. It will pull fly ash out the

exhaust instead of into the room.

b. Locate the 2 exposed rods directly underneath the

heat exchanger tubes (

Figure 20.1).

c. To clean, pull the rods straight out until it stops,

approximately 8 inches (203mm). Slide the rods

OUT and IN a couple of times.

7. Cleaning Beneath Heat Exchanger

• Frequency:

Monthly or every 1 ton of fuel

• By:

Homeowner

a. Be sure the appliance is allowed to cool, has been

unplugged and the exhaust blower is off.

b. A more thorough cleaning is needed to remove the

excess ash that is left behind from the use of the

cleaning rods for the heat exchanger tubes.

c.

The ash will be resting on the back of the baffle.

This will require removing the cast baffle. Please

refer to page 35 for a detailed explanation of

removing the baffle.

8. Cleaning the Exhaust Path

• Frequency:

Every 25 bags or monthly or more

frequently depending on ash build-up.

• By:

Homeowner

a. Appliance must be completely cool.

b.

Open cast hinge face. Remove baffle and right

brick and thoroughly vacuum the area and continue

throughout the rest of the firebox.

c.

Replace right brick and baffle and close cast

hinge face.

9. Cleaning the Hopper

• Frequency:

Monthly or every 1 ton of fuel

• By:

Homeowner

After burning approximately 1 ton of fuel you will need

to clean the hopper to prevent sawdust build-up. A

combination of sawdust and pellets on the auger reduces

the amount of fuel supply to the fire pot. This can result in

nuisance shutdowns and mis-starts.

a. The appliance must be in complete shutdown.

Allow the appliance to completely cool down.

b. Empty the hopper of any remaining pellets.

c. Vacuum the hopper and feed tube.

NOTE:

Hearth & Home Technologies recommends to

use a heavy duty vacuum cleaners specifically

designed for solid fuel appliance cleaning.

Vacuum

Exhaust Area

Right Brick

Removed

Figure 20.2

WARNING

Heat exchanger cleaning rods may be

warm to the touch. For safety purposes

wear gloves.

Do not pull heat exchanger cleaning rods

while appliance is operating.

Push cleaning rods IN when done, DO

NOT leave cleaning rods OUT. Injury

can occur.

5. Disposal of Ashes

• Frequency:

As needed

• By:

Homeowner

Ashes should be placed in a metal container with a tight-

fitting lid. The closed container of ashes should be placed

on a non-combustible floor or on the ground, well away

from all combustible materials, pending final disposal.

If the ashes are disposed of by burial in soil or otherwise

locally dispersed, they should be retained in the closed

container until all cinders have been thoroughly cooled.

Disposal of Ashes.

• Ashes should be placed in metal

container with tight fitting lid.

• Ashes should be retained in closed

container until all cinders have

thoroughly cooled.

WARNING