Operating and maintenance instructions

EN

21

LI 2333.03

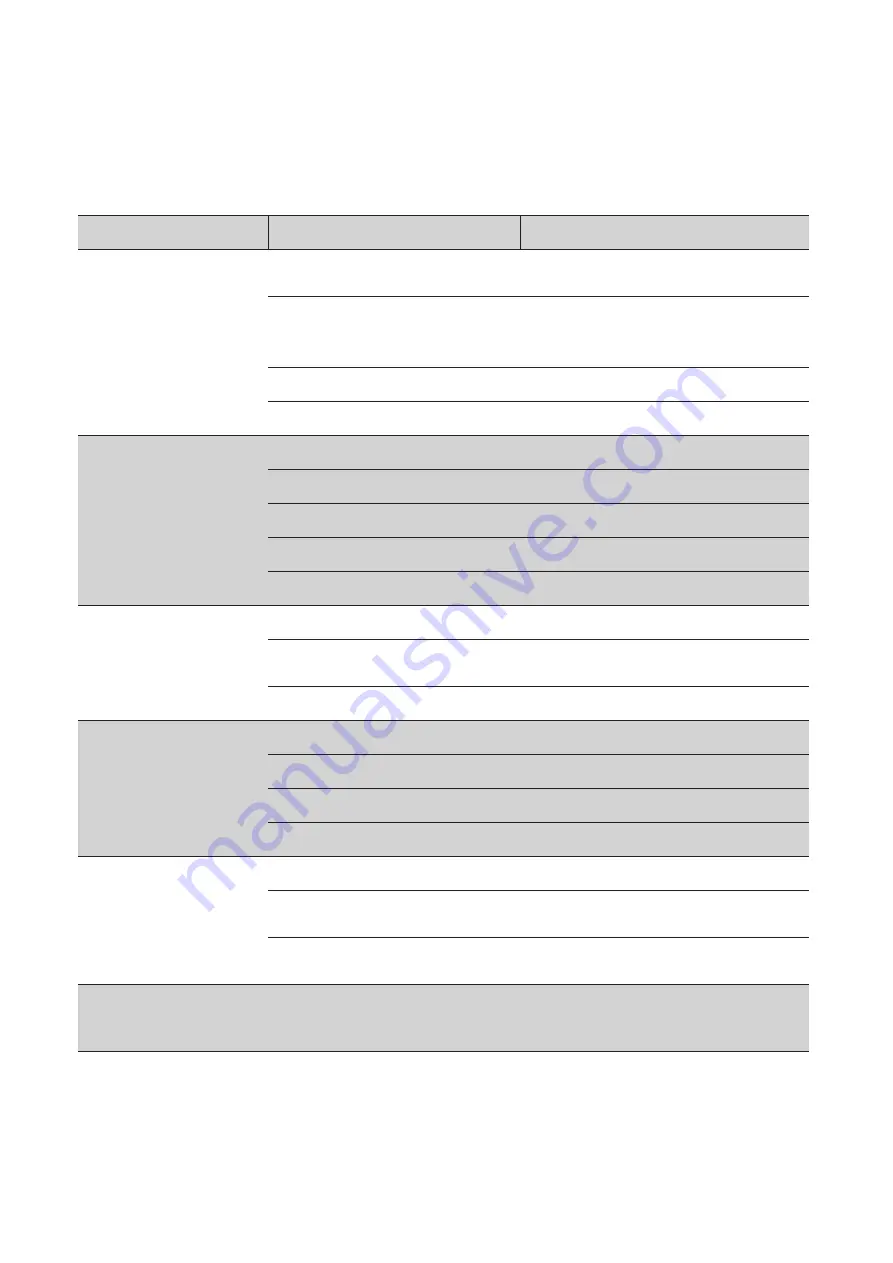

11. Troubleshooting

TROUBLE

CAUSE

REMEDY

Drop in perfomances

Inlet pipes or machine are leaking

Identify leaking point and seal it

No lubrication

Check oil level and oil conditions.

Fill with oil to the right oil level or change the

oil and the oil filter

Inlet filters are dirty

Clean or replace

Blocked oil cooler

Clean or replace

Anomalous noise

No lubrication

See previous point

Coupling element worn

Replace

Motor or pump bearings damaged

Replace

Damaged vanes

Replace

Damaged contact surfaces

Pump overhaul at our workshop

Oil leak

Shaft oil seal rings worn

Replace oil seal rings

Oil filling/discharge plugs are leaking

Check the plug has been closed / replace the

gasket

Inefficient oil recovery system

Check and clean oil recovery pipe

Motor protection is tripping

Blocked exhaust filters

Replace exhaust filters

No lubrication

Oil level filling up

Pump seizure and jam

Pump overhaul

Broken vane

Replace vanes

Discharge oil mist

Inefficient exhaust filters

Replace exhaust filters

High temperature due to polluted oil

Oil change

High operating temperature due to high

ambient temperature

Decrease room temperature by allowing a

better air exchange

Oil is found in the inlet

circuit

Inefficient inlet valve

Check the inlet valve is tight.

Clean the valve and change any damaged

parts