8 |

P a g e

System Sizing

All PURETEC UV systems are rated for a specific flow rate in water that meets the quality param-

eters on page 5.

PLEASE NOTE

that increasing the flow above this rating or disinfecting water

that does not meet the quality parameters will decrease the dose and therefore compromise the

microorganism inactivation.

If you need to determine your maximum flow rate, you can fill a 1 gallon bucket with water and

time how long it takes to fill up. It is always better to oversize your system then to undersize. For

example, if your pump delivers 8 gpm it is recommended to install any of the PURETEC 10 gpm

systems.

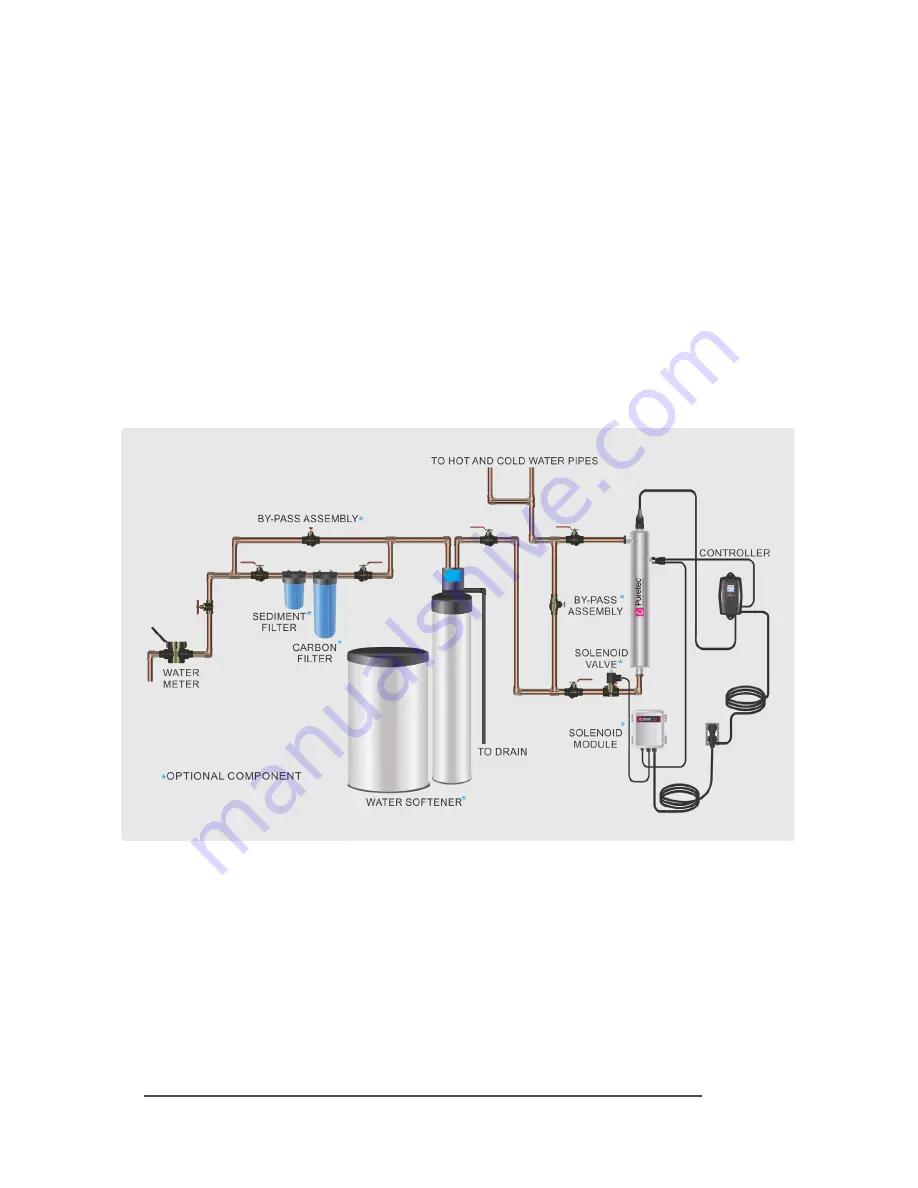

Location

For Point of Entry (POE) systems, choose a location where the main cold water line is accessible.

The system must be installed after other water treatment equipment (softener or filters), but

before any branches (See Figure 1). For Point of Use (POU) systems, install the unit just before

the faucet. PURETEC recommends that a 5 micron filter be installed

before

the UV system for a

final polishing step before the water is disinfected.

Figure 1. Recommended POE Installation Location

To facilitate lamp removal, ensure there is enough space at the lamp connector end to safely

remove the UV lamp and/or quartz sleeve (See Figure 2).

The controller will require a ground fault circuit interrupter (GFCI or GFI) outlet and should be

mounted beside or above the reactor.

PLEASE NOTE: All PURETEC UV disinfection systems are intended for indoor use only as they

should not be exposed to the elements.