Edition from 23.11.2017

5

PLD442.

Microstepping stepper motor driver

www.purelogic.ru

8 (800) 555 63 74

04. Driver functional capabilities

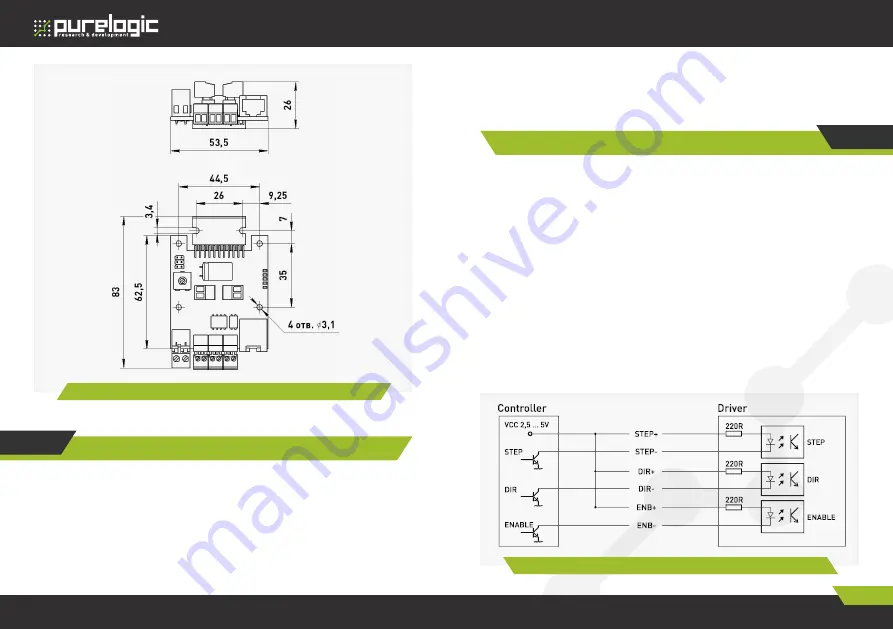

Fig. 1.

Stermotor driver PLD442 dimensions

05

Connectors, switch-overs and indication assignment

XP1 – clip connector of driver power supply

XP2, XP3, XP4 – clip connectors of input signals connection

XP5 – connector (RJ45 type of input signals connection)

XP6, XP7 – clip connectors of stepper motor connection

XP8 - mode switching contacts

LED1 – POWER signal indication.

LED2 – ERROR signal indication.

LED3 – ENABLE signal indication.

LED4 – STEP signal indication.

LED5 – DIR signal indication.

Controlling signals connection to stepper motor driver

Controlling signals connection

PLD442 driver controls a stepper motor using standard signals

STEP/DIR/ENABLE.

STEP/DIR/ENABLE signals are allocated to connectors XP2, XP3,

XP4 and RJ45 — XP5-type and are galvanically separated from the

controller.

As STEP signal frequency is increased, LED4 intensity also changes.

The scheme of differential input device and connection method to

the controller with outputs ‘open collector’ type is shown in fig.2.

STEP signal characteristics are working voltage 3 ... 5V, current

consumption is 20mА, min signal duration is 10 ms. Stepper motor step

is performed on signal’s back edge.

DIR signal’s characteristics – working voltage 3 ... 5V, current

consumption is 20mА, action time is 200 ns before/after STEP’s front

edge.

06

Fig. 2.

Differential inputs device