4

SECTION A :

wood or wood electric furnaces

INTRODUCTION.

To get maximum performance from your PSG furnace, keep in mind the following:

•

Comply with local codes (if in doubt, contact your local heating specialist).

•

Make sure your furnace is installed according to the instructions on the certification plate.

•

Make sure that your furnace has been installed in accordance with the required standards specified on the

furnace’s certification labels.

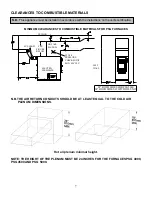

1. CHIMNEY AND DRAFT

This furnace must be connected to a chimney approved for wood-burning appliances; the chimney connector for a

PSG 2000 must have 6" diameter; 7” for PSG3000 and PSG4000, for all other models, use an 8" diameter chimney

connector.

Use of a barometric draft control is recommended in order to regulate the draft to the recommended setting.

Never use a manual chimney damper.

The barometric control must be adjusted so that the maximum draft measured at the furnace outlet does not exceed

-0.06 in. w.c.

Please note that a draft exceeding -0.06 in. w.c. could produce an uncontrollable fire.

On the other

hand, the minimum draft required is -0.04 in. w.c. in the evacuation pipe on the wood side, no matter what type of

furnace (PSG Wood, PSG Wood/Electric and PSG Wood/Oil).

2. SAFETY RULES

GENERAL REQUIREMENTS

•

Never light your furnace using chemicals or other liquid fuels. Never installed automatic feeder on that unit.

•

Do not burn wood coated with paint, glue or chemical products.

•

Never store wood near the furnace. Respect the required minimum clearances between combustibles and

your furnace.

•

Keep your furnace, chimney and smoke pipe connector clean and in good working order at all times. We

recommend that you establish clear procedures for wood storage, system maintenance and operation of

your furnace. Check creosote accumulation daily until you can determine by experience how often to clean.

Weekly cleanings may be necessary in mild weather, while a monthly cleaning may be all that is required

during the colder months of the year.

•

Keep loading and ash drawer doors shut during operation and make sure their gaskets are in good

condition. To get a replacement gasket, contact your PSG dealer.

•

A plentiful supply of combustion air and a vigorous fire will help prevent creosote accumulation.

All controls adjustments must be performed by a qualified technician. The controls settings and the blower speed must

conform to the recommendations of the National Warm Air Heating and Air Conditioning Association and respect the

recommended static pressure ranges in the warm air bonnet of the furnace (see General Technical data static

pressure).