12

FAQ

-

Printer

maintenance

and

issues

12.1

Regular

maintenance

12.1.1

Bearings

Every

couple

hundred

hours,

the

smooth

rods

should

be

cleaned

with

a

paper

towel.

Then

apply

a

little

bit

of

general

purpose

machine

oil

on

the

smooth

rods

and

move

the

axis

back

and

forth

a

couple

of

times.

This

cleans

the

dirt

and

increases

longevity.

If

you

feel

the

axis

is

not

running

smoothly

anymore,

bearings

can

be

taken

out

and

greased

on

the

inside

(they

need

to

be

removed

from

axis

because

the

plastic

lip

will

prevent

the

grease

from

getting

inside).

Super-lube,

or

any

other

multi

purpose

grease,

will

do.

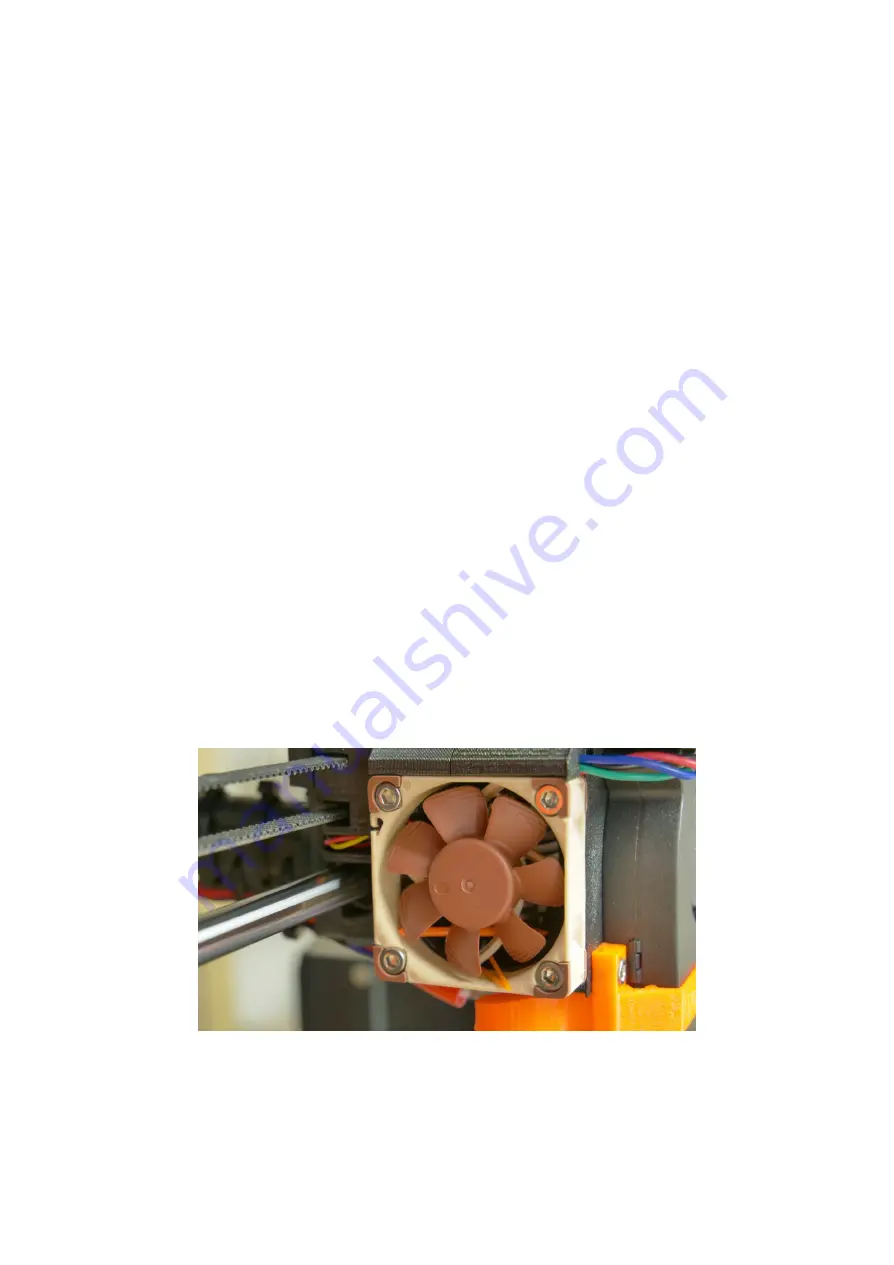

12.1.2

Fans

Both

fans

should

be

checked

and

cleaned

every

couple

hundred

hours;

dust

or

plastic

build-up

can

decrease

their

efficiency

or

even

damage

them.

Computer

cleaner

spray

will

get

the

dust

away

and

tweezers

can

be

used

for

little

plastic

strands.

Both

extruder

and

part

cooling

fans

measure

current

RPM

(Revolutions

Per

Minute).

Because

of

that,

they

can

detect

any

problem

that

will

cause

the

fan

to

slow

down,

like

a

piece

of

filament

getting

stuck

in

it.

If

you

get

a

fan

error,

check

that

it

can

rotate

freely;

clear

any

debris

that

may

be

stuck

in

it.

Pict.

35

-

Nozzle

cooling

fan

from

Noctua

59