3

WARNING:

Do not alter or intentionally

misuse this equipment. Consult Capital Safety

when using this equipment in combination with

components or subsystems other than those

described in this manual. Some subsystem and

component combinations may interfere with the

operation of this equipment. Use caution when

using this equipment around moving machinery,

electrical hazards, chemical hazards, and sharp

edges. Do not loop the lifeline around small

structural members.

Prior to Each Use

: Inspect the Rebel

SRL per the Inspection List (Table 1). Do

not use the SRL if inspection reveals an

unsafe condition.

After a Fall:

Any equipment subjected

to the forces of arresting a fall or

exhibiting damage consistent with

the effect of fall arrest forces (see

Table 1) must be removed from service

immediately and sent to an authorized

service center for repair.

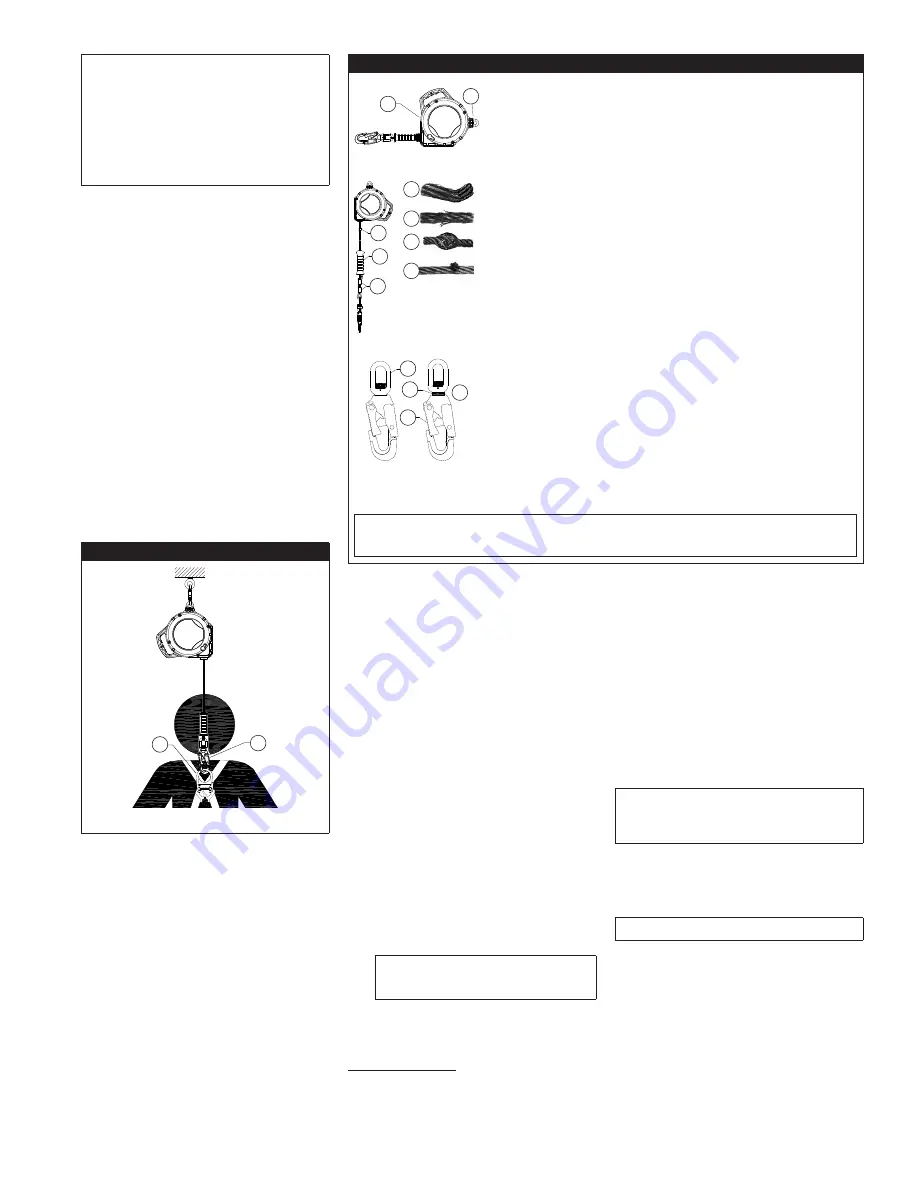

Making Connections:

After securing

the SRL to a rigid anchorage point (see

Installation

), attach the Snaphook end of

the SRL Lifeline to the dorsal D-ring on

the Full Body Harness (see Figure 5).

In situations where it is necessary to use

a front D-ring attachment point, such as

working on a fixed ladder, a Full Body

Harness with a Chest D-ring must be

used. (Refer to OSHA requirements.)

Figure 5 - Use

A

B

A

Dorsal D-Ring

B

Lifeline Snaphook

Use:

While attached to the SRL, the

worker is free to move about within

recommended working areas at normal

speeds. The lifeline should extend

smoothly and retract without hesitation.

If a slack line condition is created in

normal use the unit should be returned

to an Capital Safety for service. Should

a fall occur, the SRL will lock and arrest

the fall. Upon rescue, remove the

SRL from use. Inspect as described in

Table 1. When working with the SRL,

allow the lifeline to recoil back into the

device under control. A short Tag Line

may be required to extend or retract

the lifeline during connection and

disconnection. Allowing the lifeline to be

fully extended for long periods of time

may cause premature weakening of the

retraction spring.

INSPeCTION

To ensure safe, efficient operation, the

Rebel SRL must be inspected per the

procedures in Table 1 at the following

frequencies:

Before Each Use:

•

OSHA 1910.66,

OSHA 1926.502 ANSI Z359.1,

and CSA Z259.2.2) require an

inspection of the SRL and associated

equipment before each use. See

Table 1 for inspection procedures.

Annual Inspection:

•

ANSI Z359.1

requires a formal inspection of

the SRL by a competent person

2

other than the user. More frequent

inspections by a competent person

may be required based on the

nature and severity of workplace

conditions affecting the equipment

and the modes of use and exposure

time of the equipment. See sections

Table 1 for inspection guidelines.

Record results in the

Inspection &

Maintenance Log

on the back cover

of this instruction.

NOTe:

In Canada, CSA requires servicing

of SRLs within two year of the date of

manufacture and annual inspection thereafter.

After a Fall:

•

The SRL should be

removed from service and returned

to an authorized service center for

inspection and repair.

2 COMPETENT PERSON: One who is capable of

identifying existing and predictable hazards in the sur-

roundings or working conditions which are unsanitary,

hazardous, or dangerous to employees, and who has

authorization to take prompt corrective measures to

eliminate them.

MAINTeNANCe & SeRvICe

Periodically clean the exterior of the SRL

using water and a mild soap solution.

Position the SRL so excess water can

drain out. Clean labels as required.

Clean Lifeline with water and mild soap

solution. Rinse and thoroughly air dry.

Do not force dry with heat. An excessive

buildup of dirt, paint, etc. may prevent

the Lifeline from fully retracting back

into the housing causing a potential free

fall hazard. Replace Lifeline if excessive

buildup is present.

NOTe:

If the Lifeline contacts acids, remove the

SRL from service and wash with water and a mild

soap solution. Inspect SRL before returning it to

service.

Additional maintenance and servicing

procedures must be completed by

an authorized service center. Do not

attempt to disassemble the SRL.

NOTe:

Do not lubricate any parts in the SRL.

STORAGe

Store the SRL in a cool, dry, clean

environment out of direct sunlight. Avoid

areas where chemical vapors may exist.

Thoroughly inspect the SRL after any

period of extended storage.

Table 1 - Inspection Procedures

SRL

A

B

Inspect the SRL for loose bolts and bent or damaged parts.

•

Inspect the Housing (A) for distortion, cracks, or other damage.

•

Inspect the Swivel Eye (B) for cracks or damage and verify that it swivels freely.

•

Ensure the SRL locks up when the Lifeline is jerked sharply. Lockup should be

•

positive with no slipping.

Inspect the entire unit for signs of corrosion.

•

verify that all labels are present and are fully legible (see

•

Labels

).

Lifeline

A

F

G

B

C

D

E

verify that the Lifeline pulls out and retracts fully without hesitation or slack in

•

the line.

Inspect the Reserve Lifeline payout. If a fall has been arrested with most of the

•

lifeline out, the Reserve Lifeline may have been deployed. Pull the Lifeline out of

the SRL until it stops. If a red band (A) is visible, the Reserve Lifeline has been

spent and the SRL must be serviced by and authorized service center before

reuse.

Inspect the entire Lifeline Cable for cuts, kinks (B), broken wires (C), bird-caging

•

(D), welding splatter (E), corrosion, chemical contact areas, or severely abraded

areas.

Slide the Cable Bumper (F) up and inspect the ferrules (G) for cracks or damage

•

and the cable for corrosion or broken wires.

Snaphook

B

D

A

C

Inspect the Snaphook for signs of damage or corrosion.

•

verify that the Gate (A) opens and closes correctly and the Swivel (B) rotates

•

freely.

Inspect the Snaphook Impact indicator. If the Snaphook is in

•

‘Indicated Mode’

(C); as indicated by an exposed red band (D), the SRL has been subjected to an

impact load and should be removed for service by an authorized service center.

Do not attempt to reset the Impact Indicator.

Connectors & Full Body

Harness

Inspect Anchorage Connectors for damage, corrosion, and proper working

•

condition.

Inspect the Full Body Harness per the manufacturer’s instructions.

•

AfTeR INSPeCTION: Record Inspection results in the Inspection & Maintenance Log (see back cover). If

inspection reveals an unsafe or defective condition, remove from service immediately and contact an

authorized service center for repair.