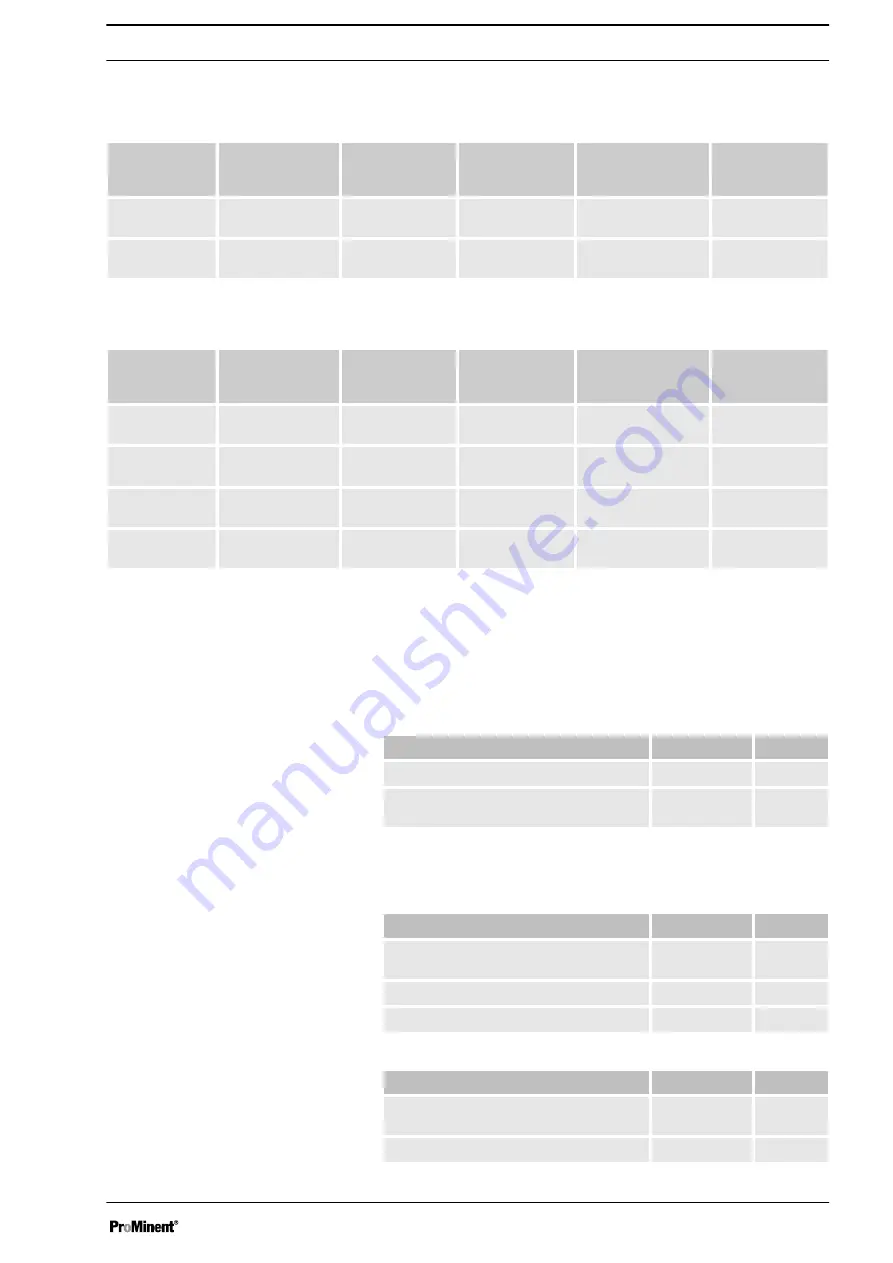

14.3 Wetted materials

DN 25 ball valve

Material version Liquid end, suc‐

tion/pressure con‐

nector

Seals*

Valve balls

Valve seats

Integral relief

valve

PVT

PVDF

PTFE

Glass

PTFE

PVDF / FPM or

EPDM

SST

Stainless steel

1.4581

PTFE

Stainless steel

1.4401

PTFE

Stainless steel /

FPM or EPDM

DN 32 plate valves

Material version Liquid end, suc‐

tion/pressure con‐

nector

Seals*

Valve plates /

valve springs

Valve seats

Integral relief

valve

PPT

PP

PTFE

Ceramic / hast. C

+ CTFE**

PTFE

PVDF / FPM or

EPDM

PCT

PVC

PTFE

Ceramic / hast. C

+ CTFE**

PTFE

PVDF / FPM or

EPDM

PVT

PVDF

PTFE

Ceramic / hast. C

+ CTFE**

PTFE

PVDF / FPM or

EPDM

SST

Stainless steel

1.4581

PTFE

Stainless steel

1.4404 / Hast. C

PTFE

Stainless steel /

FPM or EPDM

* Metering diaphragm is PTFE coated

** The valve spring is coated with CTFE (resistance similar to PTFE)

14.4 Ambient conditions

14.4.1 Ambient temperatures

Data

Value Unit

Storage and transport temperature

-10 ... +50 °C

Ambient temperature in operation (drive +

motor):

-10 ... +45 °C

14.4.2 Media temperatures

Data

Value Unit

Max. temperature long-term at max. oper‐

ating pressure

60 °C

Max. temperature for 15 min at max. 2 bar

100 °C

Minimum temperature

-10 °C

Data

Value Unit

Max. temperature long-term at max. oper‐

ating pressure

45 °C

Max. temperature for 15 min at max. 2 bar

60 °C

Pump, compl.

PP liquid end

PC liquid end

Technical data

47

Содержание 040830 SST

Страница 54: ...Dimensional drawings 54...

Страница 55: ...Dimensional drawings 55...

Страница 56: ...Dimensional drawings 56...

Страница 57: ...Dimensional drawings 57...