5

2.3 OPERATION

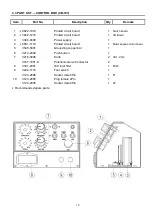

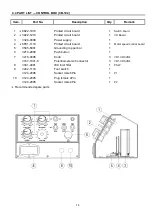

WORK / OFF/MOVE Toggle Switch (SW2)

WORK

:

Enable the system in “WORK procedure” standby. Press/release the footswitch to start “WORK

procedure”. Faceplate rotates according to timer VR1-VR4.

OFF

:

Reset error and stop work procedure.

MOVE

:

Enable the system in “MOVE” procedure standby. Press the footswitch to start the rotation, and

release footswitch to stop the rotation. Rotation speed varies according to VR1 or SW3 setting.

NORMAL / RAPID Toggle Switch (SW3)

NORMAL

:

Faceplate rotation speed varies according to WELD SPEED Knob (VR1).

RAPID

:

Faceplate rotates with maximum speed.

WELD / TEST Toggle Switch (SW4)

WELD

:

Welder output(P2) will be enabled when faceplate start rotating in either WORK or MOVE (SW2)

procedure.

TEST

:

Welder output (P2) is disable in WORK/MOVE procedure.

Note

:

Welder output (P2) type : Relay dry contact.

Speed Adjustment Knob (VR1)

Adjust rotation speed. CW to increase rotation speed. CCW to decrease rotation speed.

Weld Timer Knob (VR2)

Active in WORK procedure. Weld Timer is the duration of rotation after footswitch is triggered. Adjustable

between 1~60 second.

Start Delay Knob (VR3) (CB-102 only)

Active in WORK procedure. Start delay is the time delay before faceplate rotation. Adjustable between

0-9.9 second.

Overlap Knob (VR4) (CB-102 only)

Active in WORK procedure. Overlap is the time delay after faceplate has hit the home sensor before

faceplate stops rotation. Adjustable between 0-9.9 second

STOP Button

Press to stop the all control. Rotate CW/Pull to reset.

Homing Sequence (CB-102 only)

Homing sequence activates automatically when below condition are met.

A. Right after placing WORK / MOVE toggle switch (SW2) in WORK position.

B. 2 seconds after end of “WORK procedure”.

C. Flipping Forward/Reverse (SW1) switch in “WORK procedure” standby.

D. Reset the STOP button in “WORK procedure” standby.

Note

:

Homing sequence is divided into 2 stages. Faceplate first rotates in half of maximum speed until

home sensor is triggered and stops. Then faceplate rotates according to VR1 setting to trigger

the home sensor again. Problem may rise in second stage when VR1 is adjusted too small.

Warning

:

Homing sequence is a semi-automatic process that activates when above conditions

are met. Operator caution is advised.

Variable Speed Foot Switch (Option)

Variable foot switch change welding speed as a percentage of VR1. Example1, Set weld speed

knob 100% and external variable foot switch 50%, the resulting rotation speed is 100% x 50% =

50%. Example2, Set weld speed knob 50% and external variable foot switch 50%, the resulting

rotation speed is 50% x 50% = 25%.

Содержание PT-103

Страница 2: ......

Страница 13: ...6 2 4 TIMING DIAGRAM CB 102...

Страница 17: ...10 4 1 PART LIST MECHANISM PT 103...

Страница 19: ...12 4 2 PART LIST MECHANISM PT 203...

Страница 22: ...15 5 1 CIRCUIT DIGARM CB 101 CB 102...