serviced. This check should be carried out with

the grinding equipment detached

s01

1

370

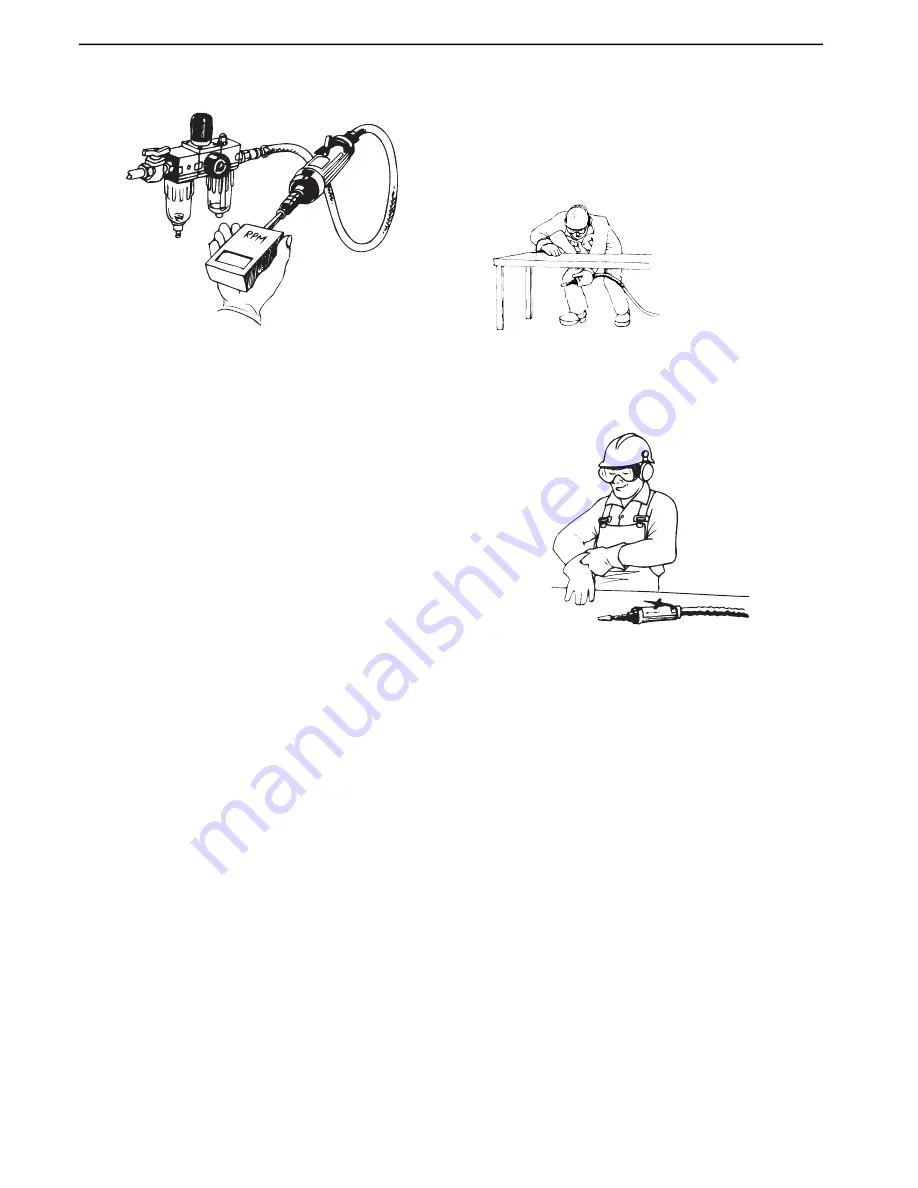

• Use a pressure regulator to avoid excessive air

pressure which may cause overspeed

• Connections and air hose must be in good condi-

tion

Mounted wheel and carbide burr

T

WARNING Air under pressure can cause

serious injury

►

Always shut off air supply, drain hose of air

pressure and disconnect tool from air supply when

not in use, before making any adjustments to the

machine, e.g. changing accessories, or when

making repairs

T

WARNING Wrong insert tool can burst and

cause serious injury or death

►

Use insert tool with max operating speed higher

or equal to the airgrinder speed

►

Do not use other insert tool than specified by the

manufacturer (no cutting off wheels or router bits).

See Section

Design and function

.

• Use only recommended sizes and types of abras-

ives

• Do not use mounting wheels that are chipped or

cracked, or may have been dropped

• Correct mounting is necessary to prevent injury

from broken mounted wheels

• Ensure the shaft diameter of the accessory is cor-

rect for the size of collet

• Do not mix mm shanks with inch collets and vice

versa

• Observe a min of 10 mm axial grip of the shank

• When fitting mounted wheels or burrs, reduce the

overhang by pushing the shank all the way into

the collet (Check also the recommendations given

by the tool manufacturer)

• Observe that increased overhang of shank reduces

permissible speed

• Before starting the machine, check that the collet

is properly tightened

• Test run every new mounted wheel in a safe posi-

tion for 30 seconds. Be sure to use a barrier (such

as under a heavy work table) to stop any possible

broken wheel parts. Stop immediately if vibration

is excessive

Correct working with the die grinder

Read the Section

Safety instructions

before using the

die grinder.

s011390

T

WARNING Failure to follow correct working

practices can result in serious injury or death

►

Ensure that the workpiece is properly supported

►

Ensure that sparks do not cause a hazard to people

or materials

►

There is a risk of electrostatic discharge if the tool

is used on plastic and other non-conductive mater-

ials

►

Personal protective equipment must be used as

described in Section

Personal protective equip-

ment

►

Slip/Trip/Fall is a major cause of serious injury

or death. Watch out for excess hose left on the

walking or work surface

►

Proceed with care in unfamiliar surroundings.

Hidden hazards may exist, such as electric or

other utility lines

►

Maintain a balanced body position and firm foot-

ing

►

React quickly to excessive vibration due to dam-

aged, or improperly mounted insert tool

►

Keep away from rotating drive spindle and abras-

ives. Rotation may continue for several seconds

© Atlas Copco Tools - 9836 3963 00

6

G2424-S120

Safety and operating instructions

Содержание G2424-S120

Страница 60: ...http www osha gov USA http europe osha eu int Europe T Atlas Copco Tools 9836 3963 00 60 G2424 S120...

Страница 61: ...T T T T T T 61 Atlas Copco Tools 9836 3963 00 G2424 S120...

Страница 64: ...10 mm 30 s011390 T 5 10 0 5 cm3 Lubricating Engineers LE3752 EP Atlas Copco Tools 9836 3963 00 64 G2424 S120...

Страница 71: ...http www osha gov http europe osha eu int T 71 Atlas Copco Tools 9836 3963 00 G2424 S120...

Страница 72: ...T T T T T T Atlas Copco Tools 9836 3963 00 72 G2424 S120...

Страница 74: ...T T 6 7 600 700 7 700 T s011370 T T 10 Atlas Copco Tools 9836 3963 00 74 G2424 S120...

Страница 75: ...30 s011390 T 5 10 0 5 3 Lubricating Engineers LE3752 75 Atlas Copco Tools 9836 3963 00 G2424 S120...

Страница 134: ......

Страница 135: ......