10 -

PRM 90

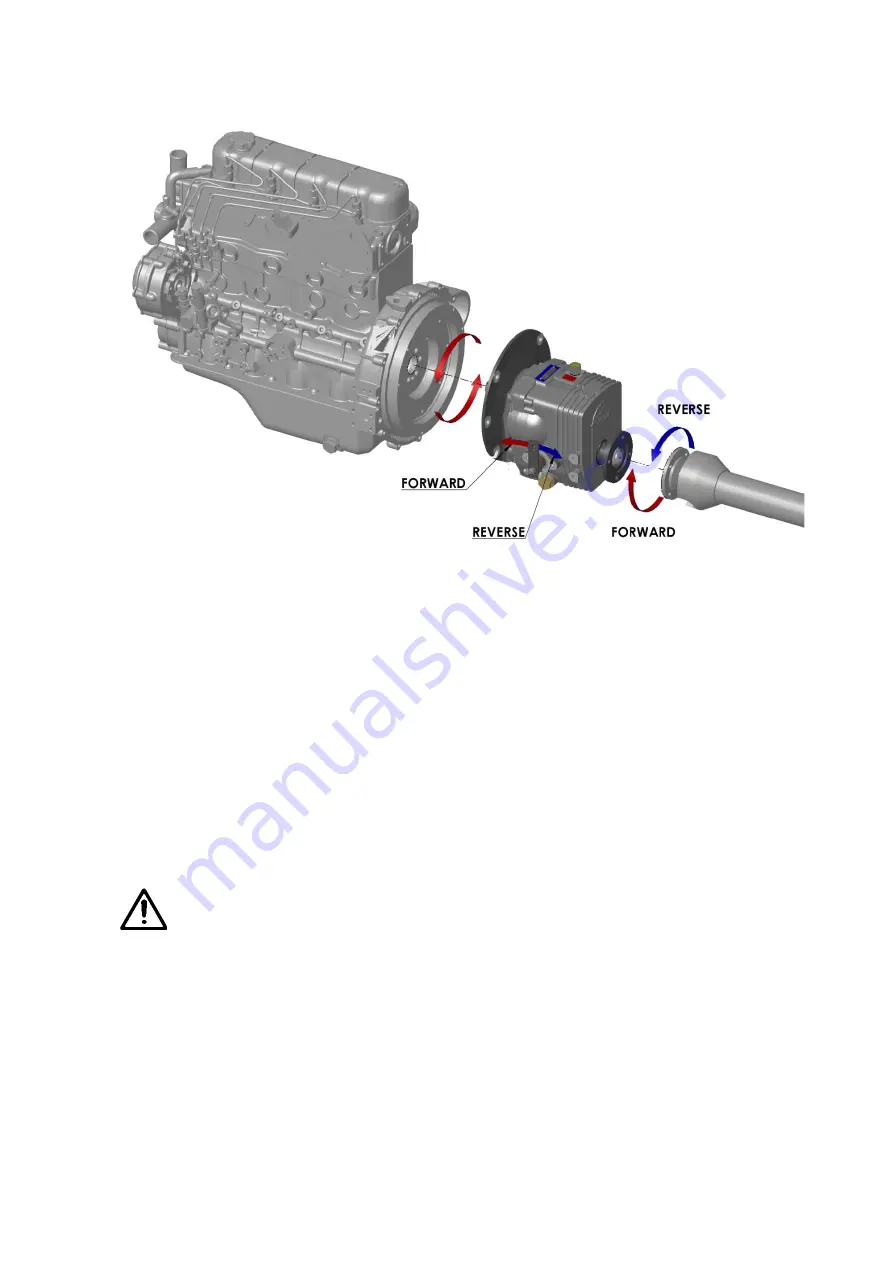

5.4 Mounting the gearbox to the engine

1.

Mount the drive plate to the flywheel, using an alignment mandrel if available, and bolt to the flywheel. Where

components to SAE standard are used, the outside diameter of the drive plate should be a close fit in the register

on the flywheel.

If a mandrel is not available, tighten the bolts just sufficiently to prevent free movement, assemble the gearbox to

the drive plate and rotate the engine two or three revolutions by hand to align the plate.

Tighten up two or three opposite bolts. Remove the gearbox and fully tighten all the drive plate bolts.

2.

Apply a layer of water-repellent grease to the input shaft spline and then offer the gearbox and adaptor up to the

drive plate and flywheel housing. Insert the gearbox input shaft into the centre of the drive plate (it may be

necessary to rock the shaft slightly to ensure the splines align). Press the assembly fully into position, align the

holes in the adaptor with those on the flywheel housing and tighten fully. See fastening torque chart 10.2.

5.5 Alignment to Propeller Shaft

CAUTION:

Alignment between the propeller shaft and the mating flange on the gearbox output

shaft is extremely important since excessive vibration and stress may lead to premature failure if

correct alignment is not achieved.

In the majority of boats whose hulls are rigid enough to prevent excessive flexing in heavy sea conditions, (which could

cause the engine and transmission to shift relative to the propeller shaft), it is generally considered preferable to couple

the propeller shaft direct to the gearbox output flange by means of a rigid coupling.

The two main conditions when a flexible coupling should be used are:

a) in boats whose hulls are not sufficiently rigid to prevent the flexing referred to above,

b) in cases where the engine is mounted on flexible mounts.

In both instances, the flexible coupling helps to isolate engine vibration or other movement from the propeller shaft thus

enabling correct alignment with the propeller shaft and stern tube to be maintained.

Whether a solid or flexible coupling is used, it is extremely important that the following points are carefully checked:

Содержание PRM90

Страница 1: ...PRM 90 WORKSHOP MANUAL...

Страница 2: ......

Страница 23: ...21 PRM 90 13 Exploded view and Cross section Figure 5 Exploded view and cross section...

Страница 24: ...22 PRM 90...

Страница 25: ...23 PRM 90...

Страница 26: ...24 PRM 90...

Страница 28: ...26 PRM 90 NOTES...