11

N

2

Control

The N2 Control monitors and controls the devices related to the production of nitrogen, such as the nitrogen generator and

the compressor. The N2 Control receives information from the Ox Control that determines whether nitrogen is needed in the

protected area. The N2 Control reacts to this signal by activating the nitrogen generator and the compressor. It also controls

the valves in the nitrogen supply lines, so that the nitrogen is blown into the right room. During nitrogen production, the N2

Control monitors whether production is proceeding as it should. For example, it measures the flow of compressed air to the

nitrogen generator (when used) and measures the nitrogen flow to the protected room. It also checks for errors in the related

devices such as the compressor, dryer, filters and humidity sensor by means of sensors and switches.

The N2 controller can control up to three nitrogen generators. If it is necessary to control several nitrogen generators, this is

done with additional N2 controllers.

Ox Control

The Ox Control monitors and controls the devices in and around the protected space that are related to the oxygen reduction

process. It receives its information from the Oxysensors located in the protected space. According to the measurements of

the Oxysensors, the Ox Control determines how much nitrogen is required to maintain the oxygen-reduced atmosphere. This

nitrogen demand is then communicated to the N2 Control. The Ox Control also uses the measurements from the Oxysensors

to monitor deviations. If the oxygen level becomes too high or too low, the Ox Control generates an error or alarm message

that is visible on the ECD display and indicated by a flashing light and/or a slow whoop. The Ox Control also checks the status

of the power supply. The Ox Controls installed as a leading or redundant controller are not different from each other and are

always constructed in the same way.

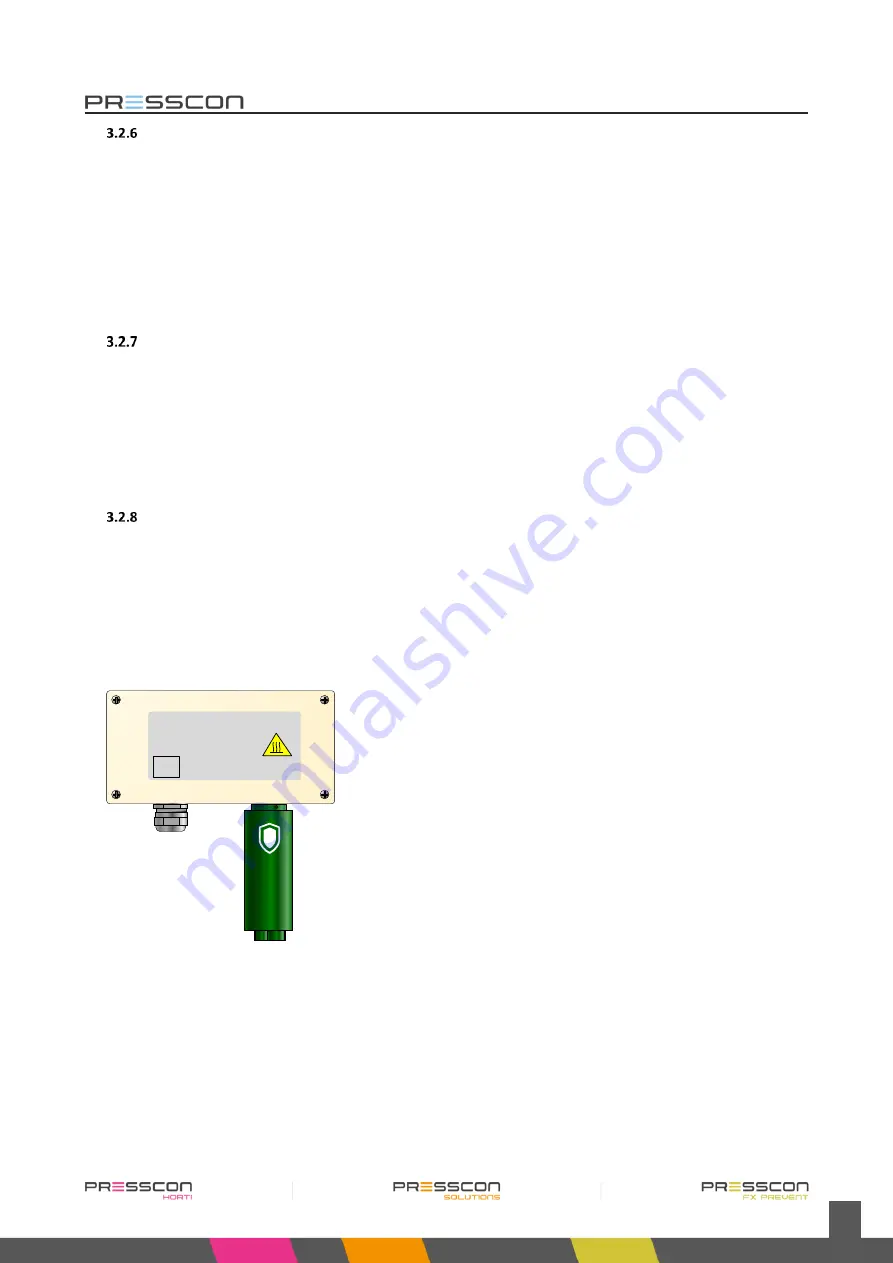

Oxygen sensors

Accurate monitoring of the oxygen concentration in the protected area is essential. On the one hand, the oxygen content

must not become too low because of accessibility for people. On the other hand, the oxygen content must not become too

high in order to ensure fire safety.

High-quality oxygen sensors are used to measure the oxygen content. The measuring principle is based on zirconium

elements that measure the oxygen content.

Depending on the size, shape of the room and the objects in the protected area, several oxygen sensors are used. The

measuring signal is sent to the Ox controller(s). There are always at least three sensors applied.

FX

P

re

vent

Number: 500

Serial: 12345678

VdS

FX Prevent

Oxygen sensor

Figure 3: Image of the oxygen sensor

The oxygen measurement is registered and interpreted by the Ox controller. If the oxygen percentage in the protected area

rises above the trigger level, additional nitrogen is blown in. The oxygen percentage is controlled within an adjustable

bandwidth.

If a single sensor shows a large deviation, this may indicate an abnormal oxygen content or a defect. This is immediately

indicated by an alarm message.

The oxygen sensors are part of the LOX installation and are therefore not described separately in this manual. Operation

takes place via the LOX controller.

Содержание LOX

Страница 2: ...2 ...

Страница 8: ...8 Figure 1 Schematic setup of the LOX system basics ...

Страница 45: ......

Страница 46: ......