Page 5

For technical questions, please call 1-888-866-5797.

ITEM 69733

SAFETY

Op

ERA

TION

M

AINTENANCE

SETU

p

20. Parts, especially exhaust system components,

get very hot during use. Stay clear of hot parts.

21. Do not cover the engine or

equipment during operation.

22. Keep the equipment, engine, and

surrounding area clean at all times.

23. Use the equipment, accessories, etc., in

accordance with these instructions and in the

manner intended for the particular type of

equipment, taking into account the working

conditions and the work to be performed. Use of

the equipment for operations different from those

intended could result in a hazardous situation.

24. Do not operate the equipment with known

leaks in the engine’s fuel system.

25. WARNING: This product contains or, when

used, produces a chemical known to the State

of California to cause cancer and birth defects

or other reproductive harm. (California Health

& Safety Code § 25249.5,

et seq.

)

26. When spills of fuel or oil occur, they must be

cleaned up immediately. Dispose of fluids and

cleaning materials as per any local, state, or

federal codes and regulations. Store oil rags in

a bottom-ventilated, covered, metal container.

27. Keep hands and feet away from moving parts. Do

not reach over or across equipment while operating.

28. Before use, check for misalignment or binding of

moving parts, breakage of parts, and any other

condition that may affect the equipment’s operation.

If damaged, have the equipment serviced

before using.

Many accidents are caused

by poorly maintained equipment.

29. Use the correct equipment for the application.

Do not modify the equipment and do not use the

equipment for a purpose for which it is not intended.

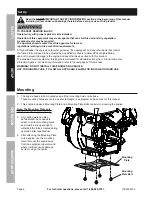

Service precautions

1.

Before service, maintenance, or cleaning:

a.

Turn the engine switch to its “OFF” position.

b.

Allow the engine to completely cool.

c.

Then, remove the spark plug

cap from the spark plug.

2. Keep all safety guards in place and in

proper working order. Safety guards include

muffler, air cleaner, mechanical guards,

and heat shields, among other guards.

3.

Do not alter or adjust any part of the

equipment or its engine that is sealed by the

manufacturer or distributor. Only a qualified

service technician may adjust parts that may

increase or decrease governed engine speed.

4. Wear ANSI-approved safety goggles,

heavy-duty work gloves, and dust

mask/respirator during service.

5. Maintain labels and nameplates on the equipment.

These carry important information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

6. Have the equipment serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the equipment

is maintained. Do not attempt any service or

maintenance procedures not explained in this

manual or any procedures that you are uncertain

about your ability to perform safely or correctly.

7. Store equipment out of the reach of children.

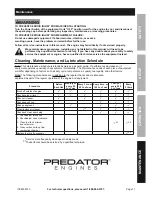

8. Follow scheduled engine and

equipment maintenance.

Refueling:

1. Do not smoke, or allow sparks, flames,

or other sources of ignition around the

equipment, especially when refuelling.

2. Do not refill the fuel tank while the

engine is running or hot.

3. Do not fill fuel tank to the top. Leave a little

room for the fuel to expand as needed.

4. Refuel in a well-ventilated area only.

5. Wipe up any spilled fuel and allow excess

to evaporate before starting engine.

To prevent FIRE, do not start the engine

while the smell of fuel hangs in the air.

SAVE THESE INSTRUCTIONS.

Operating precautions (cont.)